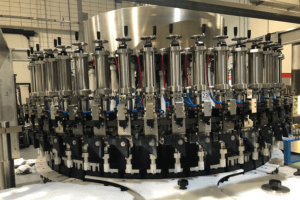

Complete Rinse-Fill-Cap Monoblock Packers for Spirits

Shemesh is a member of the American Craft Spirits Association

Shemesh Automation offers a range of complete rinse-fill-cap monoblock packers engineered specifically for the packaging of alcoholic spirits.

With speeds of up to 300ppm, the very latest models in the range feature fully automatic:

- “No bottle no spray” injection rinsing

- Tankless Pressure Gravity Filling

- Single-Head or Rotary Cappers for ROPP, Guala, T-Cork, Screw and GPI caps

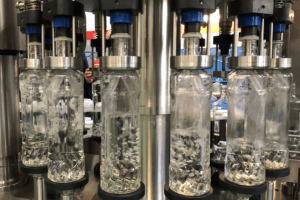

Perfect for the demands of Spirits packaging, our Tankless Pressure Gravity Filling models offer you a competitive edge through the following features:

- PERFORMANCE: the monoblocks are able to perform at a higher speed thanks to the air return valve mechanism and the physical angle of filling

- EASY TO CLEAN: the Tankless and Recirculation system allows for enhanced performance of the CIP (Clean In Place) process

- LESS MAINTENANCE: pistons are not required for lifting bottles, unlike many common industry solutions, therefore the machine requires less maintenance and a reduced chance of technical issues

- BETTER FILLING TECHNOLOGY: our Tankless Pressure Gravity Filling Models don’t use Vacuum pumps, and therefore offer a more gentle filling system to protect the scent and flavour of your product.

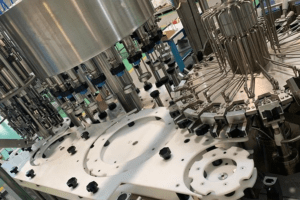

Our range of Rinse-Fill-Cap monoblock packers for spirits include the following premium spec as standard:

- Machine structure made from stainless steel AISI 304, placed on adjustable feet built from resistant material

- Machine complete with safety protection in stainless steel AISI 304, built according to CE norms, integrated into the machine structure.

- Every part touching the product is in stainless steel AISI 304

- Equipped with a device to contain and recover the filling product that could be poured accidentally – reducing waste!

- Stainless steel electric board with low voltage controls, placed at machine side

- All devices involved with the transfer and movements of bottles are made of HD polyethylene to ensure the minimum wear and fully silent functioning

- Complete stainless steel bottles conveyor

- Complete with electrical photocells placed on entry and exit to stop the machine when no bottles are detected.

Inline Solutions for Spirits Packaging

Shemesh Automation also has a complete range of in-line packaging machinery dedicated to the safe and efficient packaging of alcoholic beverages. From ATEX protected lines to proprietary filling nozzles for foaming and spill prevention, Shemesh has the experience and know-how to cater for your Alcohol filling and packaging machine needs.

Our tried and tested lines, purchased by some of the biggest names in the food & beverage industry include:

- Automatic Feeding machines

- Automatic Dosing & Liquid Filling machines

- Automatic Thermo-Sealing machines

- Automatic Capping Machines

- Automatic Labelling Machines

- Automatic Form, Fill and Seal Case Packing machines.

ATEX Protection

Alcohol-based solutions dictate that your equipment is duly fitted to professionally handle these delicate environments. Years of experience in the field means we can create for you the exact protection you need. Your production will be safe and stable, while your people and equipment are well protected, keeping your facility at the top of the range.

STANDARD Alcohol Filling Machine SPECS

With speeds of up to 300ppm, all Shemesh machinery is offered with these high-end specs as standard:

- Industry 4.0-ready

- FESTO (Germany) pneumatics and servo systems

- Complete SST304/316L design

- FDA approved piping as applicable

- SIEMENS (Germany) PLC, HMI and MOTORS

- BANNER sensors

- E-stop buttons and safety interlocks wired through CAT IV safety controller

- CE/OSHA Marking.