A guide to flexible packaging machines

In this article we’ll spotlight the flexible packaging revolution taking place around the world as manufacturers seek more sustainable options for their product packaging.

We’ll also explore the latest flexible packaging machinery innovations that are helping manufacturers to realise savings and efficiencies that give a real boost to their bottom line.

What is flexible packaging?

Flexible packaging utilizes flexible materials to provide a lightweight, versatile, and cost-effective means of protecting and preserving products. Unlike traditional rigid packaging, flexible packaging conforms to the shape and size of the product, offering excellent adaptability and customization options. It encompasses a wide range of materials such as paper, plastic, films, and more, catering to diverse packaging needs across multiple industries.

Which sectors benefit most from the advantages of flexible packaging?

We’ve worked with customers all around the world to help them automate their flexible packaging operations. We’ve found that customers in these sectors have benefited the most from making the switch to flexible packaging:

Adoption of flexible packaging is helping wipes manufacturers to unlock savings, enhance their sustainability credentials and present their brand in more creative and visible ways when compared with traditional canister packed wipes.

Flexible packaging plays a pivotal role in the food and beverage industry, ensuring product freshness, enhancing shelf appeal, and providing convenience to consumers. It is widely used for packaging snacks, candies, bakery products, dairy items, beverages, and more.

Pharmaceutical and Healthcare Sector

Flexible packaging solutions are crucial in the pharmaceutical and healthcare sectors, where precision, safety, and hygiene are paramount. Packaging formats like blister packs, sachets, and pouches help preserve the integrity of medications, medical devices, and diagnostic kits, ensuring their efficacy and protecting them from external contaminants.

Flexible packaging finds extensive usage in the personal care and cosmetics industry. It offers convenience, portability, and aesthetic appeal for products like shampoos, lotions, creams, makeup, and toiletries. Sachets, tubes, and pouches are commonly employed, making these products easily accessible to consumers.

What are the benefits of using flexible packaging?

Manufacturers who opt for flexible packaging are reporting a wide range of benefits –for themselves, the consumer and the environment.

These include:

- Cost savings in shipping and transportation due to its lightweight nature

- Extended product shelf life through the use of high-barrier films

- Minimized risk of product damage during handling and transportation

- Customizable packaging options to meet specific requirements and enhance shelf appeal

- Convenient handling, storage, and on-the-go consumption options for manufacturers and consumers

- Reduced waste and lower carbon footprint

- Efficient inventory management with compact packaging design

- Brand differentiation an increased sales through customizable designs and branding elements

What are the different types of flexible packaging?

At Shemesh, we believe gaining a true understanding of each and every product we come into contact with, enables us to squeeze extra ROI out of every single machine we engineer for our customers. Therefore, it’s important to take a look at the various types of flexible packaging found on the market today. These include:

Paper-based Flexible Packaging:

Paper-based flexible packaging solutions are commonly used for dry goods, snacks, confectionery, and various food products. They are often preferred due to their eco-friendly nature, recyclability, and ability to provide barrier properties when combined with appropriate coatings.

Plastic-based Flexible Packaging:

Plastic-based flexible packaging is widely adopted in the food and beverage, personal care, pharmaceutical, and consumer goods industries. Plastic films offer excellent barrier properties, extending the shelf life of perishable products and protecting them from moisture, light, and oxygen.

Film-based Flexible Packaging:

Film-based flexible packaging involves the use of thin films. These films can be transparent, translucent, or opaque, and are commonly used for packaging products like snacks, frozen foods, beverages, and non-food items. Film-based packaging offers exceptional flexibility, durability, and printability, allowing for attractive product displays and branding opportunities.

Flexible packaging materials

These materials cater to diverse packaging needs, balancing factors like barrier protection, flexibility, sustainability, and cost-effectiveness for various products and industries.

- Plastic Films: Common materials like polyethylene (PE), polypropylene (PP), polyester (PET), and polyvinyl chloride (PVC) offer flexibility, durability, and barrier properties.

- Aluminium Foil: Provides excellent barrier properties against moisture, oxygen, and light, commonly used in laminates and pouches.

- Paper: Eco-friendly option for flexible packaging, used for paper bags, folding cartons, and other paper-based packaging solutions.

- Laminates: Combinations of different materials, such as plastic films, foil, and paper, offering enhanced barrier properties, strength, and customization options.

Using flexible packaging does come with many challenges though when it comes to automation of the packaging process with flexible packaging machinery.

For example, because of the inherent ‘give’ in a flexible pack, manufacturers rely even more heavily on their filling machinery to be accurate. If a rigid bottle is under or over filled, the result would be visually obvious, however flexible packaging can hide a multitude of sins!

Also, whilst rigid containers can withstand fairly robust handling, flexible packages require a much lighter machinery touch.

Furthermore, rigid bottle openings are generally consistent in size and remain open until a lid is placed on top of it. Flexible pouches, for example, need to be held open during the filling or loading process and potentially a blast of air to keep the rest of the pouch from coming together and preventing an accurate fill.

This is where choosing an experienced flexible packaging machinery manufacturer becomes so important – saving you money, waste and headaches down the line!

Shemesh has engineered not one, but two flexible packaging machinery series’ to ensure the specific needs of every market sector are catered for.

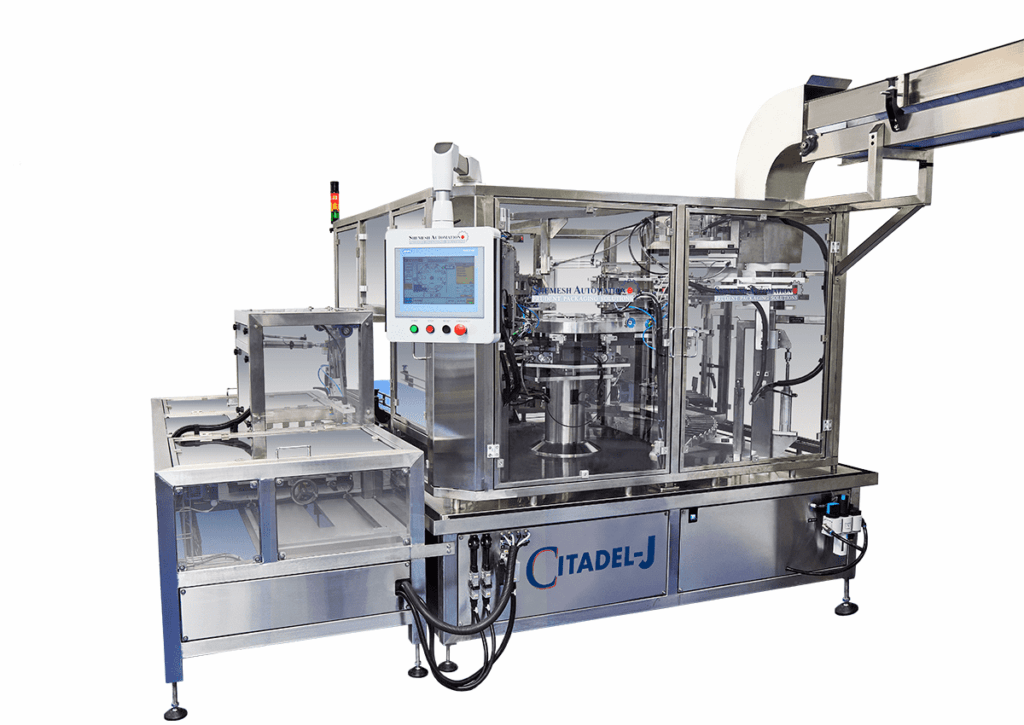

CITADEL Complete Monoblock Packer for Wet Wipes in Flexible Packs

Shemesh is first to market with an all-in-one system designed specifically to serve the jumbo round wipes in flexible packaging market.

The tried and tested all-in-one monoblock design of the Citadel-J encompasses all aspects of round wipes downstream packaging from Jumbo bags feeding, roll stuffing, liquid filling, bag sealing with full built-in QC at speeds of up to 12ppm!

Its sister machine, the CITADEL-R utilises the same cutting-edge technology to pack consumer/refill sized flexible packs at speeds of up to 30ppm.

The all-new Citadel A can fulfil both jumbo bags (Citadel J) and consumer refill bags (Citadel R) in one packaging solution, unlocking major savings for flexible pack wipes manufacturers.

The Citadel-J encompasses all aspects of round wipes downstream packaging from Jumbo bags feeding, roll stuffing, liquid filling, bag sealing with full built-in QC at speeds of up to 12ppm!

Benefits of the CITADEL Series

- Throughput: 8-12ppm (jumbo bags) up to 30ppm (refill/consumer packs)

- Direct and easy integration to the rewinding unit

- Closed bags opening feature

- All welded to pharma sanitary standards using 316/304 stainless steel

- Designed for operational flexibility and ultra low, tools free sub 40 minutes format parts changeover – reducing downtime!

- INDUSTRY 4.0 READY: SECOMA SiteManager 1139 modem, integrated into the machines’ HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback.

- Advanced QC including multiple check-weighers significantly increasing efficiency

- Enhanced, height-adjustable anti-overflow, proprietary designed filler nozzles. Portioning tolerance of 0.5% of filling volume – reducing waste!

- Bag inflation: bags are inflated with the exact amount of air needed to facilitate speedy opening and rolls stuffing

- Two-stage filling, minimising foaming and spillover whilst achieving a higher throughput

- A newly developed design for wipes bag loading Easy-to-access ‘smart’ controls with multiple HMI’s around the Citadel for simple operation

- Adjustable rewinder-to-Citadel throughput technology

- Air evacuation

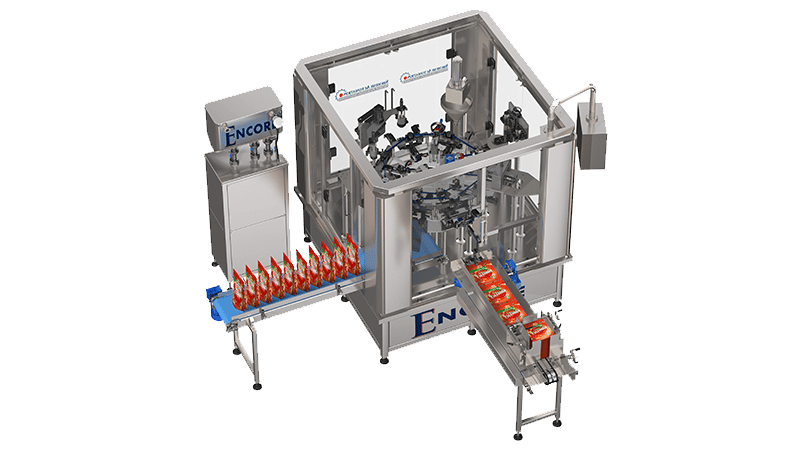

ENCORE – The Complete Monoblock Pouch Filling Machine For Food, Beverages, Cosmetics, Or pharmaceutical Products In Flexible Packs.

Building on the success of CITADEL, Shemesh engineered a similarly game-changing flexible packaging solution for general packaging applications.

The Encore Pouch Filling Machine is a robust, fully automatic, servo driven vertical index machine. It is specifically designed as a single block for the downstream packaging of liquid, solid food, tablets or powder in flexible bags.

Representing the state of the art packaging technology the Encore includes fully filling, portioning and sealing and functions as a hands-free turnkey unit.

SA’s unique Encore monoblock has a filling range of 50ml to 5L and operates at speeds of up to 30ppm/60ppm (regular size), 12-15 (jumbo size).

Book a free flexible packaging consultation with a Shemesh expert today!

Start your journey to installing a cutting-edge ultra-low downtime, waste-reducing, ROI boosting flexible packaging line at your plant today.

Contact us to discuss the optimal solution for your product with one of our industry-leading engineering experts and you could be benefitting from increased savings and productivity sooner than you think!