Automatic Liquid Filling Machines

What is an Automatic Liquid Filling Machine?

An automatic liquid filling machine is advanced packaging equipment designed to dispense precise amounts of liquid into bottles, jars, vials, or pouches with minimal human intervention. For example, whether you require a bottle filling machine for food and beverage or a liquid filling machine for chemicals, these solutions help companies streamline their packaging operations.

In addition, liquid filling machines maximize production efficiency and ensure consistent product quality. As a result, Shemesh Automation’s liquid filling machines are trusted by leading manufacturers worldwide.

How Does a Liquid Filling Machine Work?

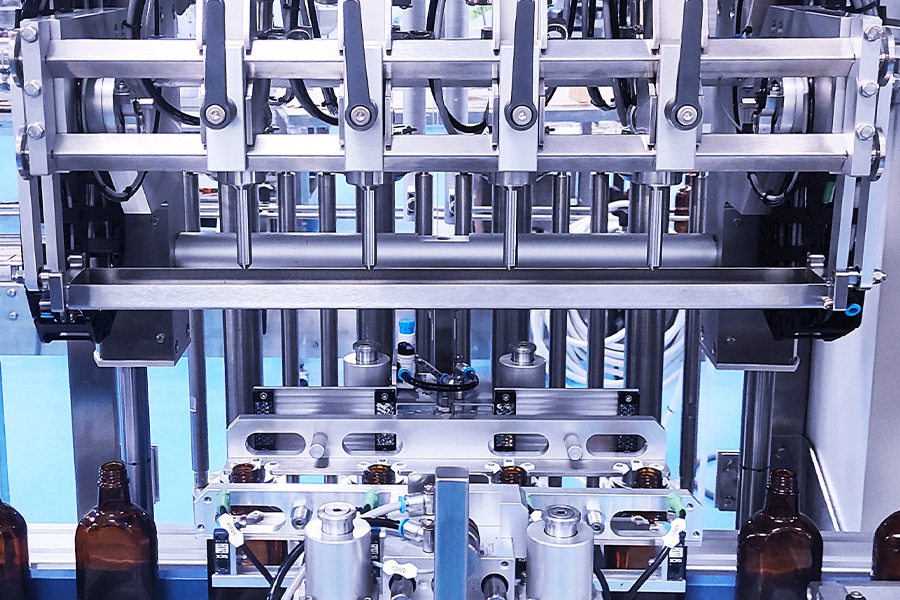

A liquid filling machine automates the filling process by moving empty containers along a conveyor. Then, it accurately dispenses liquid using piston, gear pump, gravity, peristaltic, or net weight technologies. For instance, automatic sensors, nozzles, and servo drives ensure high-speed, consistent filling while reducing waste.

Consequently, automatic liquid filling machines integrate seamlessly into your existing production line and can be customized for a wide variety of applications. Furthermore, these machines can handle a wide range of viscosities, from water to creams.

What Are the Benefits of an Automatic Liquid Filling Machine?

- Consistent and Reliable: Each container is filled to the exact programmed level, improving quality and reducing errors.

- Flexible: Automatic filling machines accommodate a wide range of products and container types.

- Easy to Use: Touchscreen controls and automated settings simplify operation.

- Clean and Hygienic: Designed for easy cleaning, minimizing contamination risks.

- Cost-Effective: Reduced labor and product waste help you save on operational costs.

- Low Maintenance: Durable components and modular construction ensure hassle-free servicing.

What Are the Different Types of Automatic Liquid Filling Machines?

There are several main categories of automatic liquid filling machines, each ideal for specific applications, products, and sectors. For example, piston filling machines and gear pump filling machines both deliver high accuracy, but are suited to different liquids and container types.

Piston Filling Machines

Piston filling machines use pistons to measure and fill liquids with a wide viscosity range. Therefore, they are perfect as a filling machine for liquid foods, creams, or viscous products.

Gear Pump Filling Machines

Gear pump filling machines use gear pumps for high-speed, precise filling, especially for larger volumes and variable viscosities. As a result, these liquid filler machines offer flexibility for manufacturers.

Gravity and Overflow Fillers

These liquid filling machines are best for free-flowing or foaming liquids, such as water, spirits, or juices. In addition, they are popular in the beverage and cosmetics sectors.

Net Weight Filling Machines

Net weight filling machines use weighing cells for ultimate precision. For instance, they are ideal for valuable or viscous liquids where accurate dosing is crucial.

Peristaltic Pump Fillers

Peristaltic pump fillers are extremely hygienic. In fact, only the tubing contacts the product, which is why they are preferred for pharmaceuticals and sensitive products.

Rotary Filling Machines

Rotary filling machines deliver continuous motion and high throughput for large-scale production. Therefore, these are the ideal bottle filling machines for food, chemical, and nonwovens industries.

Our Automatic Liquid Filling Machines

ALANTRA P+ Double Servo Driven Piston Filler and Capper Monoblock

Liquid filling machines are the flagship offering in the Shemesh Automation range. If you’re searching for a state-of-the-art filling machine for liquid products, a bottle filling machine for your packaging line, or a fully automatic liquid filling machine for bottles, jars, vials, or pouches, Shemesh Automation provides world-class solutions.

We offer a wide variety of liquid filling machine technologies to cater for a full spectrum of applications. These include:

- Servo driven piston liquid filling (linear)

- Mechanical cam control piston liquid filling (rotary)

- Gear pump liquid filling (linear)

- Flow meters (magnetic/mass) (linear or rotary)

- Gravity liquid filling (rotary)

- Net weight liquid filling (linear or rotary)

- Peristaltic pump liquid filling

A range of liquid filling methodologies available to suit your application

Key Applications for Automatic Liquid Filling Machines

Liquid filling machines and automatic filling machines play a vital role at the core of most packaging lines within the food and beverage, pharmaceuticals, cosmetics, chemicals, and nonwovens sectors. In fact, from maintaining consistent control and smooth movement of containers to filling them with the exact amount of liquid, these machines are responsible for much of the final product quality.

Therefore, it’s essential that your liquid filling machinery is engineered to maximize efficiency and adaptability. This can include specialist features-such as Shemesh’s double-servo-driven diving nozzles-designed to minimize waste for foaming liquids by providing precise speed and depth control.

Performance and Flexibility

- Accurate

- Consistent

- Fast

- Economical

- Robust

- Flexible

Because of these features, Shemesh liquid filling machines are chosen worldwide for demanding applications.

Products and Containers

Shemesh has over 30 years of experience delivering high-performance automatic filling machines and liquid filling machines for products including:

- Soft Drinks

- Spirits

- Creams and lotions

- Shampoo and Soaps

- Hand sanitizer

- Soups

- Syrups

- Sauces

- Pickles and Chutneys

Furthermore, our machines can fill all container types common to these sectors, including bottles, buckets, jars, pouches, PET containers, canisters, tubes, syringes, and vials.

Our range of automatic liquid filling machines and liquid filler machines delivers high performance for all these applications, and many more.

Machine Range

STRATUM – Servo Driven Piston Liquid Filling Machine (Linear)

From water, peanut butter and ink, to pastes, creams and paints – the Shemesh STRATUM Automatic Servo Driven Piston Filling Machine is an advanced filling machine for liquid products. Moreover, it fills a wide range of viscosities and container types, making it ideal for precise dosing and high-speed operation.

ASTERRA – Mechanical Cam Control Piston Liquid Filling Machine (Rotary)

ASTERRA is a high performance mechanical cam, positive displacement, small footprint, low utilities, sustainable Rotary Piston Filling Machine. As a result, this automatic filling machine delivers high reliability for a wide viscosity spectrum.

Asterra is suitable for both low viscous products such as fruit juices and high viscous products with or without solids, such as sauces, pastes, tomatoes, honey, puree, jam, and wax.

FGW – Gear Pump Liquid Filling Machine (Linear)

FGW is a positive displacement linear automatic liquid filling machine. In addition, its gear pump technology allows for a wide viscosity range and high-volume fills, especially for buckets and pails.

For example, the FGW is perfect for filling wet wipes buckets with liquid solution, using Shemesh’s specially designed shower nozzles.

SA-RGF – Low/High Vacuum Liquid Filling Machine – Gravity Filling (Rotary)

Also known as “overflow” fillers, this technology is commonly used for spirits, liquors, water, and juices. Therefore, our range of automatic filling machines is perfect for free-flowing liquids.

Falcon – Net Weight Liquid Filling Machine (Linear or Rotary)

The FALCON Net Weight Liquid Filler is engineered for challenging and abrasive liquids. For example, it can handle high viscosity products like honey and low viscosity products like juice, always with outstanding precision.

Monoblocks

Shemesh’s space-saving monoblocks offer ultra-accurate liquid filling from 5ml vials to 5L containers. For instance, complete monobloc packers use peristaltic pump technology for maximum hygiene and a portioning tolerance of just 0.5%.

Standard Machine Specifications

- Industry 4.0 ready

- Festo (Germany) pneumatics and servo systems

- Complete SST304/316L design

- FDA approved piping as applicable

- Siemens (Germany) PLC & HMI and motors. Allen Bradley – optional

- Banner sensors

- SEW motors

- E-stop buttons and safety interlocks wired through CAT IV safety controller

- CE, ANSI, OSHA, NFPA and NEC compliant

Frequently Asked Questions about Automatic Liquid Filling Machines

Why choose Shemesh Automation for my automation needs?

Shemesh Automation is a global leader in automatic liquid filling machines and complete filling lines. Our solutions offer cutting-edge technology, robust engineering, and a dedicated service team, ensuring maximum reliability and value for your business.

What warranties and after-sales support will I receive?

Every automatic liquid filling machine from Shemesh comes with a comprehensive warranty and access to our global support network. We provide technical assistance, preventive maintenance, and rapid supply of spare parts to keep your production running smoothly.

Can Shemesh customise a machine for my factory’s specific needs?

Yes, Shemesh Automation specializes in custom solutions. We can tailor any liquid filling machine-from bottle filling machines to high-speed monoblocks-to match your factory’s product types, container shapes, throughput, and specific production requirements.

Contact us for more information on the Liquid Filling Machines or for a detailed quotation.

Follow us on Linkedin