Fast and hygienic complete packaging solutions for Gummies and Candies

Shemesh has poured over 30 years of engineering know-how into a highly-innovative 60 products per minute A-Z gummies packaging line – the TKS-G60.

The TKS-G60 offers Gummies and Candies manufacturers a major advantage over their competitors – the ability to partner with a single manufacturer capable of meeting all their needs for gummy/candy packaging from product feed to palletising.

Engineered with hygiene, speed and efficiency in mind, the TKS-G60 includes:

- Automatic container unscrambling machine (mechanical for single bottle types or robotic where multiple bottle types are used)

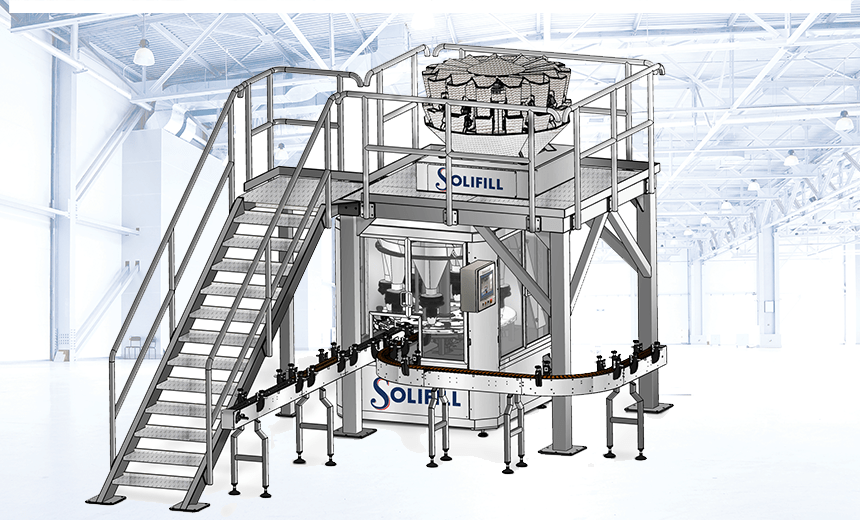

- SOLIFILL Continuous Rotary Multihead Weigher Filling Machine

- THORO Automatic Screw/Twist-off Capper

- Induction Sealing Machine

- LWA Universal Labelling Machine

- RELENTLESS Form, Fill and Seal Case Packing Machine

- APPOLON Palletizer

Solifill – Fast and Accurate Gummies and Candies Filling

The Solifill was designed for gummies and jellies, which are renowned in the food, supplements, and nutraceuticals sectors for being one of the most hard to handle products.

Operating at speeds of up to 150ppm, SOLIFILL is engineered with a number of unique processes and features that ensure gummies, candies and jellies are separated and accurately deposited into containers with wide or narrow openings, solving a problem that has plagued gummies and candies manufacturers the world over – inaccurate filling due to product ‘clumping’.

- The continuous rotary multi-head weigher based filling system dispenses a predetermined fill weight of product to the continuous motion rotary base, transferring product into the customer’s rigid container / bottle / jar through a transfer funnel.

- The bottles are fed through a timing screw into an infeed-starwheel which in turn feeds the main turret. Once in the main turret the combination scale filler is timed with the rotary platform to ensure accurate weight transfer.

- The product then travels onto a vibration section within the turret to allow for the transfer and settling of the entire dose into a narrow container / bottle opening.

Fast, hygienic changeovers

Our Gummies packaging machinery is filled with hygienic features that allow for fast changeovers, minimising downtime.

- Advanced ABB robotics and Cognex vision systems available to allow container unscrambler changeovers at the touch of a button

- Tool-less changeover

- All parts of the SOLIFILL are detachable and can be washed easily

- Complete SST304/316L design

- Small footprint for easy access and easy cleaning

- Stippled surface of the line in certain critical areas reduces the level of direct product contact

High-speed checkweighers and QC throughout the line

The TKS-G60 includes multiple checkweighers, metal detectors and QC points throughout the line to ensure pinpoint accuracy and minimise costly product lost.