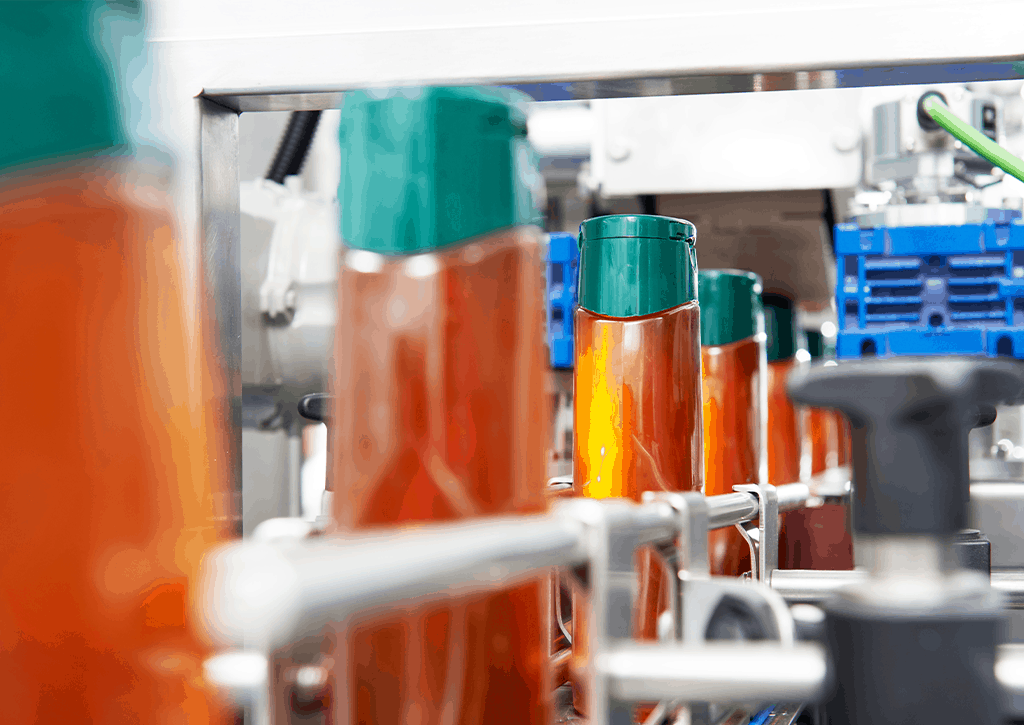

In an era where consumer choices abound, product presentation and quality preservation play a pivotal role in influencing purchasing decisions. This is where an efficiently designed food packaging line, powered by state-of-the-art food filling machines, emerges as a game-changer. Here are some of the key benefits that underscore the importance of these machines:

- Enhanced Productivity: Food filling machines automate the once time-consuming and labour-intensive task of filling containers, be they bottles, cans, pouches, or cartons. This automation drastically ramps up production speed, allowing manufacturers to meet high demand without compromising on quality.

- Precise Portion Control: Consistency is key in the food industry, and filling machines ensure precise measurements for each product. This not only maintains uniformity in taste and texture but also eliminates product wastage due to overfilling or underfilling.

- Improved Hygiene and Safety: Manual filling processes come with inherent risks of contamination. Automated filling machines minimize human contact with the product, ensuring higher levels of hygiene and food safety. Additionally, Shemesh machines are designed to meet stringent sanitation standards, making cleaning and maintenance more straightforward.

- Versatility in Packaging: Food filling machines are incredibly versatile, accommodating a wide range of packaging types and sizes. This adaptability enables producers to diversify their product offerings without the need for major retooling, saving both time and costs.

- Extended Shelf Life: Proper filling and sealing techniques are crucial for extending the shelf life of perishable products. Filling machines create airtight seals that protect products from external elements, thereby preserving freshness and flavour for longer periods.

- Cost Efficiency: While the initial investment in food filling machines might seem substantial, the long-term cost savings are significant. The reduction in labour costs, minimized product wastage, and increased output collectively contribute to improved profit margins.

- Market Competitiveness: In an industry where innovation is the driving force, adopting advanced packaging technology can give a brand a competitive edge. An efficiently designed packaging line not only ensures product integrity but also showcases a commitment to quality and innovation, resonating with consumers.

What are the Types of Food Filling Machines?

Food filling machines come in various types, each designed to cater to specific product consistencies and packaging requirements. The diversity of these machines ensures that both liquid and solid food products can be efficiently packaged. Here are the primary categories:

- Liquid Filling Machines: These machines are adept at handling a spectrum of liquids, from thin sauces and beverages to viscous oils and syrups. They employ techniques like gravity, servo-driven piston, or peristaltic pumps to ensure accurate filling without spillage.

- Solid Filling Machines: Designed for products like grains, nuts, confectionery, and more, these machines use augers, vibratory trays, or weigh scales to achieve precise filling by volume or weight.

- Paste Filling Machines: For semi-solid products like pastes, creams, and sauces, paste filling machines utilize piston-driven mechanisms or progressive cavity pumps to maintain consistent fill volumes.

- Powder Filling Machines: These machines handle powdered products like spices, flour, or protein supplements. Auger-based or volumetric filling systems ensure that the right quantity of powder is dispensed into each package.

- Counting Filling Machines: Ideal for small, individual items like pills, candies, or seeds, these machines use sensors to count and dispense a specific number of items into each package.

- Aseptic Filling Machines: For products that require a sterile packaging environment, aseptic filling machines maintain the highest hygiene standards, extending shelf life and preserving product integrity.

- Cup Filling Machines: Commonly used for yogurt, desserts, and other viscous products, these machines fill pre-made cups or containers with precision and minimal wastage.

- Pouch filling machines: Suitable for filling liquids, solids or powders into flexible bags/pouches or doypacks.

By selecting the appropriate type of food filling machine, manufacturers can optimize their packaging line to accommodate a wide range of products while maintaining efficiency and quality.

How do Food Filling Machines Work?

The STRATUM double-servo driven piston filling machine is the flagship liquid filling machine in the Shemesh range

Food filling machines are the backbone of efficient packaging lines, ensuring accuracy and consistency in product filling. They operate on three main levels: manual, semi-automatic, and automatic, each with distinct advantages.

- Manual Filling: In manual filling, operators control the filling process by hand. While cost-effective for small-scale operations, it’s labor-intensive and prone to variations in fill volume, potentially compromising product quality.

- Semi-Automatic Filling: Semi-automatic machines combine manual labor with automation. Operators place containers, and the machine performs the filling. While reducing human error, it still falls short in terms of maximizing efficiency and output.

- Automatic Filling: Automatic filling machines like Shemesh’s STRATUM double-servo-driven piston liquid filling machine stand out for their unparalleled efficiency. They handle the entire process – from container handling to precise filling and sealing – with minimal human intervention. Advanced sensors and controls ensure accuracy, while high-speed mechanisms enhance productivity.

Automatic machines excel in maintaining hygiene, reducing product waste, and accommodating various product types. With programmable settings, they effortlessly switch between different products and packaging sizes, adapting to market demands swiftly. The reduced need for constant oversight enhances productivity and reduces labor costs.

In a competitive market, where speed, precision, and consistency reign, automatic food filling machines emerge as the optimal choice. They streamline processes, boost output, and elevate product quality, making them an indispensable asset for modern food producers. For a more in-depth guide on how to choose the right food filling machine for your product, check out our blog.

What Types of Food Require Filling Machines?

Food filling machines cater to a diverse array of products, ensuring precise and efficient packaging. Some of the key food categories that greatly benefit from these machines include:

- Sauces and Condiments: Liquid or viscous sauces, including ketchup, mayonnaise, and salad dressings, are efficiently dispensed using filling machines.

- Beverages: From juices and energy drinks to water and milk, beverages of varying viscosities are accurately filled to maintain consistency.

- Dairy Products: Items like yogurt, cream, and milk require controlled filling to preserve freshness and meet quality standards.

- Edible Oils: Filling machines ensure exact quantities of cooking oils, olive oils, and other liquid fats are packaged without spillage.

- Honey and Syrups: Viscous substances like honey, maple syrup, and pancake syrup benefit from machines that provide precision filling.

- Dry Goods: Powdered products such as spices, flour, coffee, and protein supplements are measured accurately using powder filling machines.

- Snacks and Confectionery: Nuts, candies, chocolates, and other small snacks are counted and dispensed precisely by counting filling machines.

- Bakery Items: Products like cake batter, icing, and pie fillings require controlled dispensing for consistent baked goods.

- Ready-to-Eat Meals: Meals in containers, like soups and curries, are efficiently filled using cup filling machines.

- Personal Care Products: Beyond food, filling machines are used for items like lotions, shampoos, and creams, ensuring measured dispensing.

The versatility of food filling machines makes them indispensable for an expansive range of products, contributing to both efficiency and product quality across the food and beverage industry.

What Other Types of Machines are Essential for a Food Packaging Line?

In addition to food filling machines, a well-rounded packaging line requires a synergy of complementary machinery to ensure a seamless production process. Shemesh Automation’s Complete range of packaging machinery offers food manufacturers the ability to automate their entire packaging process – from product feeding and unscrambling all the way to case packaging and palletizing. These advanced solutions are all built, installed and integrated under one umbrella by Shemesh – offering food manufacturers a distinct competitive advantage.

Shemesh’s comprehensive range of food packaging machinery includes:

- Automatic Unscrambling Machines Shemesh’s fully synchronised container unscramblers reduce the need for manual operation and vastly improve the efficiency and accuracy of your line.

- Automatic Sealing Machines The most advanced automatic sealing machine of its kind in the market today, the SEALPRO cuts sealing laminate according to the specific product size and conduction-seals it accurately in position. It offers individually temperature-controlled welding heads built inside one robust sealing block, therefore delivering a consistent application of heat to ensure a perfect seal.

- Automatic Capping Machines: Applicable to call cap and container types common to the food manufacturing market, Shemesh’s range of automatic capping machines operate at speeds of up to 200ppm and ensure product integrity and extended shelf life. These machines contribute to maintaining product freshness and preventing leakage, a critical factor for liquid-based products such as sauces, beverages, and oils.

- Automatic Labelling Machines: Accurate labelling enhances brand visibility and consumer trust. Shemesh Automation’s labelling machines precisely apply labels to containers, allowing food manufacturers to showcase essential product information, branding, and regulatory compliance.

- Case Packing Machines: Shemesh’s mechanical gripper or vacuum gripper case packers ines automate the process of packing products into cases, streamlining the final packaging stage for bulk distribution.

- Robotic Palletizing Machines: Shemesh utilizes the latest robotic technology to products on pallets for easy shipping and storage, reducing manual labor and ensuring safe transport for larger quantities.

Shemesh Automation’s Core Line packaging machinery embodies innovation, precision, and reliability, essential qualities for food manufacturers aiming to achieve efficient, high-quality packaging processes. The integration of these machines into a packaging line not only enhances productivity but also ensures that products reach consumers with consistent quality and looking their very best.

Contact us to discuss your food filling machinery needs today!