Automatic Liquid Filling Machines

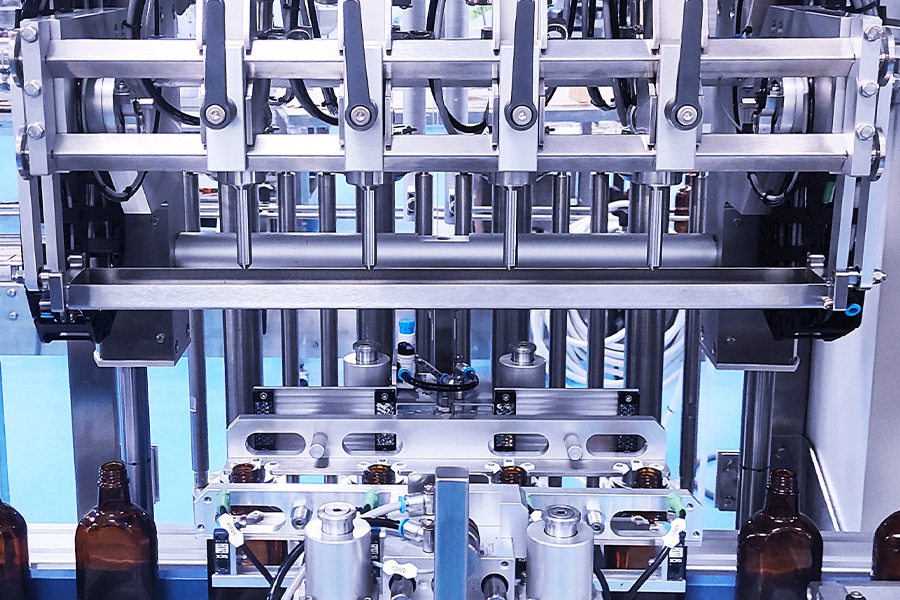

ALANTRA P+ Double Servo Driven Piston FIller and Capper Monoblock

Liquid Filling Machines are the flagship offering in the Shemesh Automation range.

We offer a wide variety of filling technologies to cater for a full spectrum of applications. These include:

- Servo driven piston liquid filling (linear)

- Mechanical cam control piston liquid filling (rotary)

- Gear pump liquid filling (linear)

- Flow meters (magnetic/mass) (linear or rotary)

- Gravity liquid filling (rotary)

- Net weight liquid filling (linear or rotary)

- Peristaltic pump liquid filling

A range of liquid filling methodologies available to suit your application

Automatic filling machine applications

Liquid fillers play a vital role at the core of most packaging lines within the food and beverage, pharmaceuticals, cosmetics, chemicals and nonwovens sectors.

From maintaining consistent control and smooth movement of the containers throughout the process – to avoid spillages – to filling the empty containers with exact amounts of the desired liquid, filling machines are responsible for a high degree of the quality of the final product. It’s to be expected therefore that these machines should be engineered specifically to maximize their ability to handle the client’s particular liquid product and containers. This can include specialist functions – for example, Shemesh utilises double-servo-driven diving nozzles to keep waste to an absolute minimum when dealing with foaming liquids. This is because with such liquids, it’s vital to have total control over the speed and diving depth of the nozzles.

As the heartbeat of any bottle filling line, liquid filler machines have to be:

- Accurate

- Consistent

- Fast

- Economical

- Robust

- Flexible

That’s why it’s incredibly important not to compromise on the quality of your liquid filling machinery.

Shemesh has over 30 years of experience delivering high-performance automatic filling machines for a broad spectrum of products including:

- Soft Drinks

- Spirits

- Creams and lotions

- Shampoo and Soaps

- Hand sanitizer

- Soups

- Syrups

- Sauces

- Pickles and Chutneys

Whilst maintaining the flexibility to handle all of the above liquid types and more, Shemesh machines are also engineered to fill all container types common to the sectors mentioned above including:

- Bottles

- Buckets/Pails

- Jars

- Flexible pouches and Doypacks

- PET containers

- Canisters

- Tubes

- Syringes

- Vials

Our range of automatic liquid filling machines are to deliver high-performance filling across all of the applications, liquid types and container types listed above- as well as a whole host of additional products. The range includes:

STRATUM – Servo driven piston liquid filling machine (linear)

From water, peanut butter and ink, to pastes, creams and paints – the Shemesh STRATUM Automatic Servo Driven Piston Filling Machine is designed to fill a wide range of liquids and particulates with a wide spectrum of viscosity levels.

ASTERRA – Mechanical cam control piston liquid filling machine (rotary)

ASTERRA is a high performance mechanical cam, positive displacement, small footprint, low utilities, sustainable Rotary Piston Filling Machine.

It is equipped with cam driven filling stations each featuring a state-of-the-art proprietary designed SA Nozzles to fill your product with near zero leaks, splashes, bubbles, or overflow with ultra-high accuracy of+/- 2ml of filling volume.

Asterra is suitable for low viscous products such as fruit juices as well as high viscous products, with or without solids like goulash, paté, sauces, pastes, tomatoes, honey, puree, jam, wax etc.

FGW – Gear pump liquid filling machine (linear)

FGW is a positive displacement linear automatic liquid filling machine. Thanks to its built-in gear pumps filling technology, the filling range of the FGW is theoretically unlimited. It is easily adjusted to fill a wide range of viscosities and is a real space saver as fewer filling heads are required for higher fill volumes.

Because of its ability to fill higher volumes, the FGW is perfect for filling buckets or pails with liquids. One classic example is the filling of wet wipes buckets with liquid solution that is evenly absorbed by the wipes roll, thanks to shower nozzles which are specially designed by Shemesh for this particular application.

SA-RGF – Low/High Vacuum liquid filling machine – Gravity filling (rotary)

Also known as “overflow” fillers, this technology is most commonly used for filling alcoholic beverages like spirits, and liquors, water and soft drinks like juice and other free flowing liquids. Our range has been developed and enhanced over time to include:

- Hygienic design attributes

- Machine durability

- Trusted brands BOM components such as PLC, HMI, Pneumatics, Sensors, motors etc. ensuring parts availability and greater serviceability

Falcon – Net weight liquid filling machine (linear or rotary)

The FALCON Net weight liquid filler is an all-new, state of-the-art, intermittent linear solution. Engineered to accommodate the most challenging and abrasive liquids, FALCON delivers high accuracy filling for a variety of products of high viscosity liquids like honey and treacle and low viscosity liquids like thin fruit juice, for example.

Monoblocks

Shemesh’s range of space-saving monoblocks also offer ultra accurate liquid filling. From 5ml vials to 5L, Shemesh’s complete monobloc packers use the latest Peristaltic pump technology to fill to within a portioning tolerance of 0.5% of filling volume.

Peristaltic pumps are a super-hygienic filling method as only the filling tubes themselves come into contact with the fluid – thus eliminating the risk of pump-fluid contamination.

STANDARD MACHINE SPECIFICATIONS

All Shemesh’s Liquid Filling Machines come with the following standard specification:

- Industry 4.0 ready

- Festo (Germany) pneumatics and servo systems

- Complete SST304/316L design

- FDA approved piping as applicable

- Siemens (Germany) PLC & HMI and motors. Allen Bradley – optional

- Banner sensors

- SEW motors

- E-stop buttons and safety interlocks wired through CAT IV safety controller

- CE, ANSI, OSHA, NFPA and NEC compliant