Flexible Packaging Machines

Shemesh Automation boasts a series of unique all-in-one Monoblock Flexible Packaging Machines, encompassing all aspects of downstream packaging including doypack feeding, filling, sealing, capping, double-capping, weighing, labeling QC and discharging.

These ultra-smart monoblock configurations are ideal for projects involving pharma, cosmetics and food and beverage for soups, nonwoven wipes, pastes and other such products.

What are flexible packaging machines?

As manufacturers look for more sustainable and efficient ways of packaging their products, the adoption of flexible packaging – such as doypacks, pouches and bags has grown substantially.

That has created a market need for fast, efficient and sustainable machinery capable of automating the process of packaging products into flexible packs.

Because of the nature of flexible packaging, this process requires multiple stages including:

- Bag/ pouch/ doypack feeding

- Bag/ pouch/ doypack opening

- Solid or liquid product filling

- Bag/ pouch/ doypack sealing

- Bag/ pouch/ doypack quality control

- Bag/ pouch/ doypack case packing

- Bag/ pouch/ doypack case palletizing

Shemesh Automation has engineered a series of flexible packaging machinery that excels at all of these operations – delivering high ROI solutions for manufacturers utilising flexible packaging.

Benefits of Monoblock Flexible Packaging Machines

- Everything you need, in one smart unit

- Small footprint

- Requires as few as 2 operators (hands-free versions also available)

- Designed for operational flexibility and ultra low, tools free sub-40 minutes format parts changeover

Why choose Shemesh Automated machines for flexible packaging?

Shemesh’s complete packaging monoblocks for products in flexible packaging create efficiencies for manufacturers that boost their bottom line and increase productivity.

Our monoblocks are designed to have the smallest footprint possible, allowing manufacturers to maximise their all-important floorspace. By having all packaging functions – feeding, filling, sealing, capping and QC carried out by one small monoblock also provides savings when it comes to maintenance and servicing.

Our monoblocks are also engineered specifically to suit our customer’s product. For example, our Citadel R model differs from the Citadel-J in that it specifically caters for consumer and refill size packs – creating another space saving! The Citadel-J however, is built to tackle the specific challenges posed by the packaging of jumbo sized wet wipes into jumbo bags. As you’d expect, the machine is engineered to seamlessly to carry out its function whilst saving as much space as possible – the vertical wipes stuffing station is a perfect example of this as it takes up far less floorspace than a horizontal wipes stuffer would.

Top Monoblocks in the Shemesh range include the:

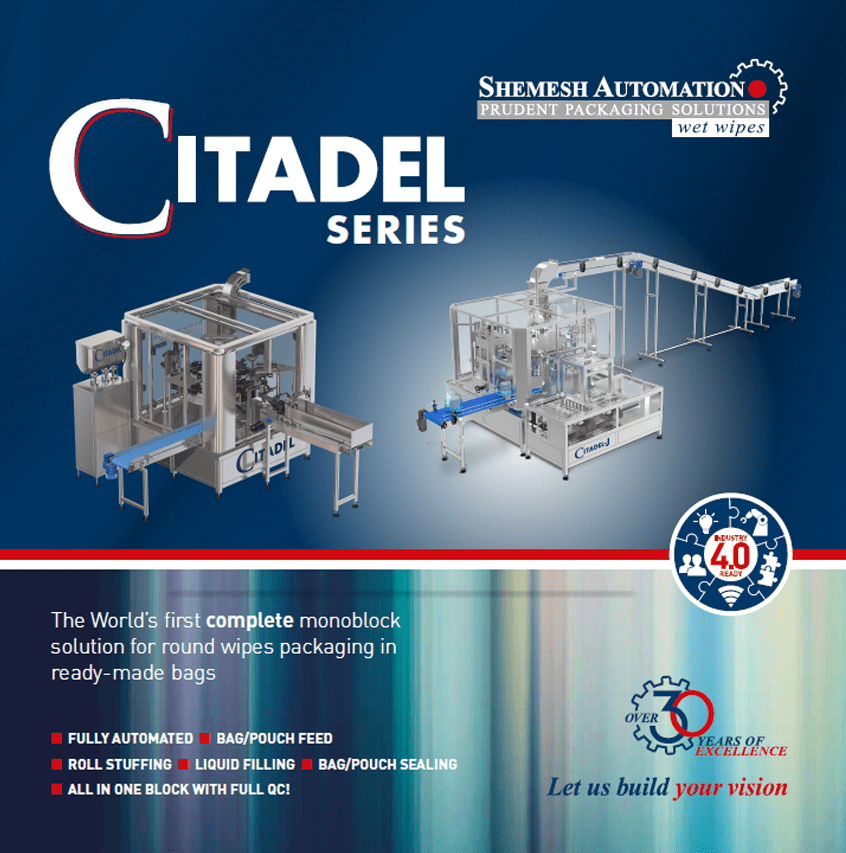

CITADEL

Fully Automated Package Machine – Bag/Pouch Feed, Roll Stuffing, Liquid Filling, Bag/Pouch Sealing, All-in-One Block with Full QC.

Built on decades of industry experience supporting the wipes manufacturing sector with our in-line, high throughput downstream packaging portfolio, Shemesh Automation is once again first to market with an all-in-one system designed specifically to serve round wipes in the flexible packaging market.

The CITADEL Automated Packaging Machine harnesses all the knowledge and innovations that were key to our globally successful XPANDER monoblock for wipes in canisters and other nonwovens packaging technologies such as the SAS120 stuffer. The tried and tested all-in-one monoblock design of the CITADEL Automated Packaging Machine encompasses all aspects of round wipes downstream packaging from bags/pouches feeding, roll stuffing, liquid filling, bag sealing with full built-in QC!

The CITADEL has a throughput of up to 30ppm (refill size)/ 8-12ppm (jumbo size) and is the only machine of its kind available on the market today — far exceeding the sophistication of existing market solutions.

ENCORE

With operating speeds of up to 60ppm, the ENCORE Pouch Filling Machine is a robust, fully automatic, servo driven vertical index machine. It is specifically designed as a single block for the downstream packaging of liquid, solid food, tablets or powder in flexible bags.

Representing the state of the art packaging technology the ENCORE includes fully filling, portioning and sealing and functions as a hands-free turnkey unit.

Shemesh’s unique ENCORE monoblock has a filling range of 50ml to 5L and operates at speeds of up to 30ppm/60ppm (regular size), 8-12 (jumbo size)

Encore is perfect for, but not limited to, applications in the following sectors:

- Food and beverages in flexible packaging (e.g. soft drinks, pet food, soups, sauces, nuts, snacks and much more)

- Cosmetics (e.g. Creams, soaps and lotions)

- Chemicals (e.g. cleaning fluid, salt and other crystals, dishwasher tablets and more)