Shemesh to launch a first-to-market Continuous Motion Capping Machine with integrated robotics and an advanced vision system

Shemesh Automation is set to launch the most versatile capping machine on the market to date. Incorporating both robotics and an advanced vision system, the ATTILUS continuous motion capping machine will break new ground for the packaging machinery industry.

The integration of robotics and an advanced vision system will allow ATTILUS to offer unmatched flexibility and enable higher speeds and enhanced accuracy in automatic caps, pumps and triggers sorting. Cap types will be changeable at the touch of a button, saving customers money by almost eliminating the need for format parts, and dramatically reducing downtime.

Shemesh has built a 30+ year reputation for delivering quality capping solutions across a range of sectors. From its THORO series, handling a wide range of snap-on, screw, twist-off caps, to more specialty models like the ALANTRA pump, spray & trigger capping machine.

Now, thanks to the introduction of integrated robotics, Shemesh has taken their capping offering to the next level with one machine that is capable of affixing trigger, pump, screw, Snap-On and other cap types, at even higher speeds.

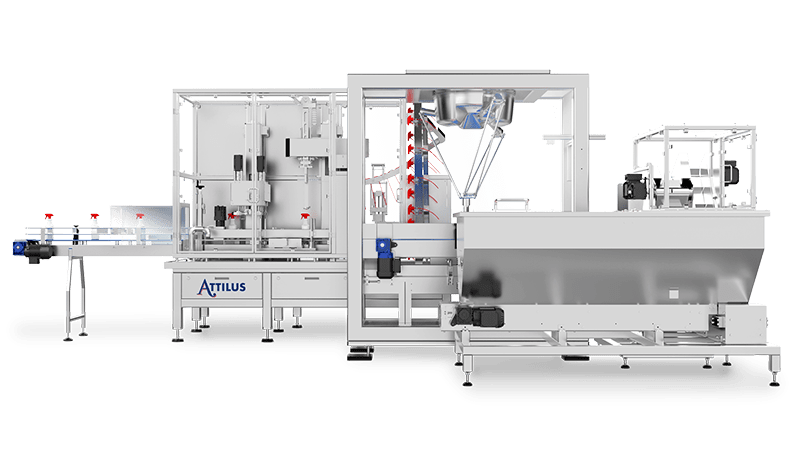

Meet ATTILUS – The Continuous Motion Capping Machine

Set for launch in September 2022, the ATTILUS utilizes the very latest robotic and vision system technologies in both the cap sorting and cap fixing phases to provide its most versatile capping machine to date.

A Robotic Sorter based on Delta Robot and an advanced vision system allows the ATTILUS to sort and orientate even the most complex screw, trigger and pump caps.

Also, the ATTILUS utilizes a pick & place Cartesian Robotic Arm (gantry two axis robot), which is servo-controlled, to track and deliver the caps to the bottles while in motion, ensuring smoother and faster production.

The ATTILUS operates at up to 80ppm and includes bottle tracking and a synchronized gantry robot based on encoders and servos. Its integrated Siemens/AB PLC & HMI puts the operator in complete control, allowing simple programming – changing formats and course of movement at the touch of a button. The Robotic enhancement of the ATTILUS also ensures changeover downtime is kept to a minimum (under 20 minutes).

The standard ATTILUS features include Servo controlled torque QC and cap position QC, as well as an array of optional features such as: vision QC system for cap position, fully automatic servo-controlled changeover which translates to under 5 mins changeover time and eliminates operators’ interventions and human error, bottle orientation for inclined neck bottles and ATEX/EX Compliance.

Of course, ATTILUS is also built to include all of the standard specifications you expect from Shemesh machinery, including:

- Industry 4.0 ready

- Minimal changeover time

- Tool free changeovers

- Festo pneumatics and Servo systems

- Complete SST304/316L design

- SIEMENS HMI & S7-1500 PLC series (Allen Bradley – optional)

- BANNER/ SICK/OMROM sensors

- E-stop buttons and safety interlocks wired through CAT IV safety controller.

- CE, ANSI, OSHA, NFPA and NEC compliant

- ABB Delta Robot

- SEW/Siemens Motors

- Cognex Vision Systems

The debut capping machine from Shemesh’s Robotics Division

Fulfilling its reputation for constant innovation, ATTILUS is the debut capping machine launched from Shemesh’s Robotics Division. Offering a wide range of solutions to meet ever developing customer needs, the Division will enhance Shemesh’s capabilities in delivering turnkey projects for downstream packaging lines.

Working closely with leading robot manufacturers and their application center teams, has allowed Shemesh to bring proven solutions to market in record time.

The introduction of robotics to the Shemesh range allows them to respond to market demand for enhanced machinery options including new small footprint depalletizing, case packing and palletizing Cobots, as well as higher throughputs full size robotic cells for Palletizer/Depalletizer solutions.

Their existing Shemesh range also receives an uplift thanks to the addition of the cutting-edge robotics. For example, the Shemesh range of Cap Sorters and Bottles Unscramblers now offers unmatched flexibility and efficiency with extremely low changeover time. The enhanced range will also include integrated Vision + Pick and Place units for parts assembly and orientation.

Shemesh Automation CEO Shai Shemesh commented; “Shemesh Automation has built a reputation for staying ahead of the curve by constantly innovating and using the latest technology to push the boundaries of what we’d previously thought possible. ATTILUS, the debut launch from our Robotics Division is the perfect example of this – with the incorporation of robotics and advanced vision technology we are able to deliver a faster, smoother, more versatile and even more accurate capping solution than ever before.”

For more info on the full range of our rotary filler and sealer machines or other filling machines visit: www.shemeshautomation.com

About Shemesh Automation:

With over 30 years in the industry, Shemesh Automation is a global leader in the high-end packaging and assembly machinery and industrial automation appliances manufacturing arena. The family-owned business supports almost 2,000 assets in over 30 countries around the world. Its nonwovens arm, Shemesh Automation Wet Wipes (www.sawetwipes.com) is a global pioneer in nonwovens downstream packaging equipment with cutting-edge technology positioned at the very forefront of the industry.

Shemesh is represented in 13 countries around the world with offices in the US, UK, France and Israel. Its London-based office coordinates global sales and marketing operations and its Israeli office managing research, development and engineering innovation. Shemesh’s unique combination of UK customer-centric service with an Israeli high-tech mentality to push the technical boundaries, plus the use of tried & tested parts from German manufacturers has greatly contributed to its success. The US market is served by a 43,055 square-foot office in Green Bay, Wisconsin, home to a Demo Center, 24 Hour Service and Parts Center and a large US installed base of packaging machines.

We don’t see Shemesh as a company that builds just cutting-edge machinery, we want to become your partner of choice for long and successful cooperation. “Let us build your vision” is not just our slogan, simply put, this is what we do, day in and day out!

For editorial or sales enquiries please contact:

Roni Levi

Marketing Director

Shemesh Automation

Telephone: +972.355.099.46

Email: roni.l@shemeshautomation.com

Website: shemeshautomation.com