Automated Capping Machines

ROBUST, VERSATILE BOTTLE CAPPING MACHINES FOR COMPLEX OR SIMPLE LINES.

From rotary systems to compact monoblocks, Shemesh Automation delivers advanced capping solutions with precise torque control, quick changeovers, and full compatibility with multiple bottle cap types – all on a single machine.

Shemesh Automation UK is your single-source partner for turnkey packaging lines – manufactured, delivered, and installed by one trusted supplier.

The Capping Process: How Shemesh Machines Fulfil Your Needs

The capping process is a vital step in packaging because it ensures product integrity, safety, and extended shelf life. It involves sealing bottles securely using different cap types, which prevents contamination and preserves the quality of the contents. Let’s explore how Shemesh Automation’s machines tackle each stage of the bottle capping process effectively:

- Preparation: The system must clean and orient the bottles correctly. Shemesh machines integrate effortlessly with your existing production line to ensure that bottles are always in the correct position, enabling efficient capping.

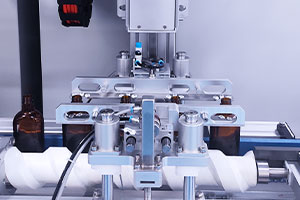

- Cap Feeding: An efficient cap feeding system is essential for smooth operation. Our capping machines feature advanced feeding mechanisms that deliver caps accurately to the sealing point, minimizing jams and maintaining continuous production.

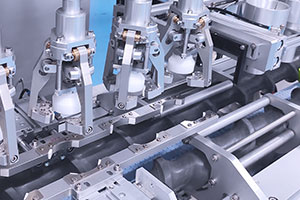

- Cap Placement: Accurate cap placement is key for a secure seal. Shemesh’s servo-driven systems position caps precisely relative to each bottle, significantly reducing the risk of misalignment and ensuring optimal results for various cap types.

- Capping Mechanism: During the capping stage, the mechanism applies the necessary torque to seal the bottle cap securely. Our machines, such as the THORO and ALANTRA, offer digital torque control, allowing precise adjustments through the HMI interface. This feature helps prevent leaks and preserves product integrity.

Our Capping Machines

- Quality Control: Quality control is the final step in the capping process. Our automated capping machines feature advanced quality control systems that verify cap placement and closure. This ensures that only bottles with properly sealed caps reach the consumer, maintaining high product standards.

With Shemesh Automation’s advanced automated capping machines, you can optimize your capping process while ensuring superior quality and efficiency. Our dedication to innovation and reliability means that we provide solutions tailored to your specific packaging needs.

Our Bottle Capping Machines – Tailored for Your Product

Shemesh designs its bottle capping machines to maximize speed and precision. Our extensive range of automatic capping machines delivers industry-leading advantages, such as:

- High Throughput: Cap between 20 to 180 bottles per minute, with options for I, II, or III capping stations.

- Industry 4.0 Ready: Equipped with Secomea Site Manager 1139 modem, integrated into the machine HMI for SMART remote support, live stats, and performance analysis.

- Versatile Handling: Efficiently manages a wide variety of container materials, including both plastic and glass.

- Cap Compatibility: Handles Twist-Off, Screw, Push-Pull, ROPP, Snap-On, Triggers, and more.

- Diverse Capping Techniques: Choose from mechanical Pick & Place or robotic capping for better flexibility.

- Digital Torque Control: Adjust torque via the HMI to meet specific cap requirements.

- Servo-Driven Quality Control: Integrated defect rejection system to validate cap placement and closure.

- Tool-Free Design: Quick changeovers in less than 20 minutes minimize downtime.

- Multiple Configurations: Choose from monoblock or linear line options to suit your production environment.

- Precision Orientation: Servo-driven systems ensure accurate cap positioning relative to the bottle.

Our Capping Machines

ALANTRA P+ Automatic Filler-Capper Monoblock

The ALANTRA P+ is the next generation of precision packaging equipment – a fully integrated monoblock that combines servo-driven piston filling with automatic bottle capping in one compact unit. Designed to maximize throughput, consistency, and hygiene, ALANTRA P+ handles pump caps, trigger caps, screw-on caps, and snap-on caps with minimal changeover time.

Ideal for industries including cosmetics, chemicals, food & beverage, and others where performance and reliability are non-negotiable, the ALANTRA P+ ensures each container is filled and capped with unmatched precision.

Featured Capping Machines

THORO Screw, ROPP & Twist-Off Capper

The THORO Multi-Container Capper Series caters to a wide range of products, providing precise, torque-measured capping. Available in both semi-automatic and fully automatic versions, it ensures leak-free capping. Major manufacturers like Beams Packaging Services and MacPhie in the UK have successfully adopted THORO.

Valextra High-Speed Snap-On Capper

The Valextra is perfect for snap-on applications, such as infant formula packages and wipes. It consistently applies round, oval, and shaped lids on containers with multiple orientation options for precise lid placement.

ALANTRA Automatic Air Pump and Trigger Nozzle Capper

The ALANTRA machine specializes in products requiring trigger nozzles and air pumps. It offers accurate, leak-free capping and includes an optional built-in quality control system that guarantees a defect rate below 1%.

ALANTRA P Automatic Capping Machine: Pump, Trigger, Screw-On & Snap-On Caps

The ALANTRA P is a versatile, all-in-one capping solution engineered to meet the varied requirements of industries such as cosmetics, pharmaceuticals, chemicals, and food & beverage. Offering advanced capabilities for handling pump, trigger, screw-on, and snap-on caps, this machine sets a new standard in automated packaging technology.

CIW Automatic Capping Machine

Designed for nonwoven wipe rolls, the CIW120 accurately caps various canister lids. It includes a lid deformation prevention mechanism and offers quick changeover capabilities for enhanced adaptability.

Attilus Continuous Robotic Trigger, Pump & Screw Capper Machine

The ATTILUS machine delivers high precision for capping screw caps, triggers, and pumps. It ensures a flawless seal and supports a variety of container shapes and cap types.

Benefits of Using Reliable Capping Machines

- Enhanced Product Integrity: Prevents leaks and contamination by ensuring secure seals.

- Improved Efficiency: Automating the capping process speeds up production and cuts labor costs.

- Consistent Quality: Precise capping pressures and speeds reduce defects, resulting in higher-quality output.

- Scalability: Easily adapts to increased production volumes with flexible solutions for various bottle types.

- Reduced Waste: Effective capping minimizes product waste, enhancing profitability.

Overcoming Industry Challenges with Shemesh Automation

The packaging industry often deals with fluctuating demand and evolving regulatory standards. Shemesh Automation’s capping solutions are built to tackle these challenges head-on, ensuring that you maintain high efficiency and compliance.

Ready to upgrade your capping process? Get a budgetary quote today!

Join us on LinkedIn to stay up-to-date with our latest news and innovations in filling and packaging solutions.