Gallery

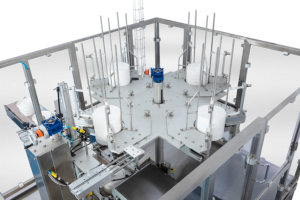

This fully automatic Bucket Lid Denester and Top Conveyor is bi-functional. First, lids are de-nested using SA’s proprietary magazine design for easy and smooth insertion.

Then, lids are picked and placed on to the moving buckets. Afterwards, each bucket with a lid on top moves under SA’s proprietary designed upper belt buckets lids wide conveyor fastener for final pressing.

The machine is available with or without the carousel and is applicable to a variety of bucket shapes (round, square, etc.).

Benefits:

- Continuous means continuous. No need to stop the line for lids loading.

- Due to integrated Siemens/AB PLC & HMI, Lid types are changeable at the touch of a button!

- Almost eliminates the need for format parts

- Dramatically reduces downtime

- Material: stainless steel SST304.

- HMI-controlled.

- Throughput: 25 lids per minute.

- Up to 120-160 lids in 4 cartridges

Get in touch with us for a quote today!