A-Z Chemicals Multi-Container Bottling Line from Feeding to Labeling

Installation, Service, Parts, Delivery & Training, under ONE umbrella

Shemesh offers an integrated and highly efficient solution for your packaging needs, whether for bottles or jerrycans. Discover why our complete line is the ideal choice for your business.

Compatibility with Chemicals Products

Our machines are designed to withstand the most demanding environments. Made from materials specifically chosen for their resistance to corrosive chemicals and equipped with explosion-proof features, they ensure long-lasting performance and optimal efficiency.

- Chemicals Corrosion and Explosion Resistance: Our equipment resists corrosive and reactive substances and is designed to be explosion-proof.

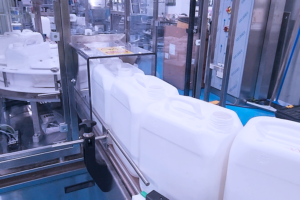

- Container Flexibility: Adapted to various viscosities and densities, our machines can fill different types of containers such as bottles and jerrycans.

Efficiency and Productivity

Our solutions are designed to maximize your productivity while ensuring consistent precision and quality.

- Production Speed: Achieve high production speeds without compromising quality.

- Automation: Reduce reliance on labor and minimize human errors with a high level of automation.

Precision & Reliability

Precision is essential to avoid waste and ensure compliance with standards.

- Filling Precision: Our automatic liquid filling machines for viscous and free-flowing liquids, ensures precise filling for each container.

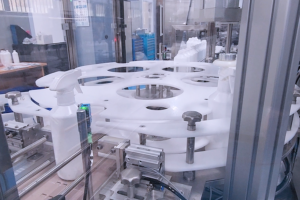

- Capping Reliability: Our Alantra Multi-Container Capper Series is designed to provide super-accurate, leak-free capping, efficient torque-measured capping for a wide variety of products guaranteeing secure and consistent results.

- Precise Labeling: Our LWA labeling machines labels your products with unmatched precision, even at high speed.

Flexibility

- Filling: Suitable for bottles and jerricans ranging from 500ml to 5000ml.

- Capping: Our machines provide flexibility to handle both trigger and screw caps efficiently, including spray pumps and more.

- Labeling: Capable of wrap-around, front and back, and side labeling and more.

Safety

- Safety Standards: Full compliance with local and international safety standards.

- Operational Safety: Equipment equipped with emergency stop devices and mechanical protections to prevent accidents.

Ease of Use and Maintenance

Our machines are designed to be intuitive and easy to maintain.

- User Interface: User-friendly control interfaces for simplified use.

- Maintenance: Easy maintenance with accessible parts and simplified maintenance procedures.

Adaptability

Our machines evolve with your needs.

- Modularity: Easily add new format modules to meet new production needs.

- Versatility: Our machines handle different types and sizes of containers and caps in sectors such as cosmetics, food and beverage, and pharma.

Quick Fact Sheet:

- As few as 2 operators can manage the process from unboxing empty bottles to palletizing filled, capped, and labeled bottles and jerrycans.

- Strikingly low changeover downtime, raw materials waste and space requirement design, leading to substantial costs savings

- Top industry standard filling accuracy

- Throughput: On demand

- NOT just generic machines but equipment designed for the specific market needs of high quality Chemicals production.

- 316 Stainless Steel & electro polished steel smart liquid tank

- ATEX-rated and machinery available

Service and Technical Support

We support you every step of the way.

- After-Sales Support: Responsive and competent technical assistance.

- Training: Training sessions for your operators and maintenance staff.

For more information about our A-Z Chemicals Multi-Container Bottling Line | Automation from Feeding to Labeling, do not hesitate to contact us.

- Choose a solution that combines efficiency, precision, and safety. Optimize your production with our complete line today!