Bottling Machines

What is a Bottling Machine?

A bottling machine is a type of packaging equipment designed to fill bottles with a variety of liquids-such as beverages, oils, chemicals, or cosmetics-and securely seal them. Used in sectors like food and beverage, cosmetics, pharmaceuticals, and household chemicals, bottling machinery helps streamline operations, reduce labor costs, and ensure product consistency.

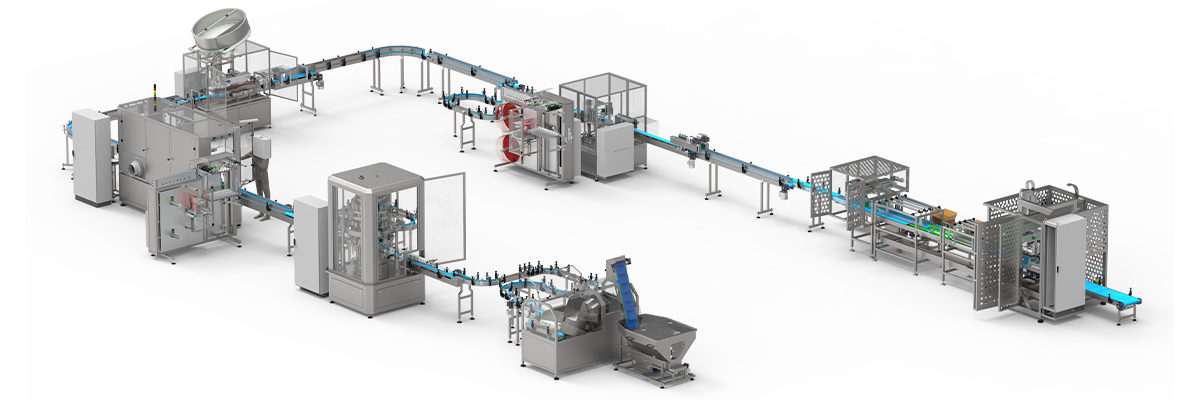

Bottling lines are production lines that fill a liquid product-often a beverage, sauce, syrup, marinade, oil, or vinegar-into bottles on a large scale. Bottling lines usually include label application equipment, capping operations, sealing & labeling application, and quality assurance verification equipment to ensure accuracy and compliance.

Where Are Bottling Machines Used?

Bottling machines are essential in industries where precise, high-speed liquid packaging is required. These include food and beverage, pharmaceuticals, chemicals, and cosmetics. For example, chemical manufacturers handling liquids and oils benefit from machines designed to maintain accuracy, safety, and hygiene throughout the filling process.

How Does a Bottling Machine Work?

A bottling machine automates the process of filling containers with liquid or semi-viscous products. Typically integrated into a complete packaging line, the machine starts by receiving empty bottles-manually or via an unscrambler-and aligns them under filling nozzles. Before filling, bottles may be rinsed or cleaned to ensure hygiene. The system then uses volumetric, gravimetric, or pressure-based technology to dispense the product. After filling, the bottles proceed to the capping and labeling stations for final packaging and may undergo vision inspection for quality control.

What Are the Benefits of an Efficient Bottling Machine?

- High throughput: Designed to handle large volumes at high speeds, reducing production time.

- Precision: Accurate dosing minimizes product waste and ensures quality control.

- Low maintenance: Engineered with premium components to reduce downtime and service needs.

- Flexibility: Easily adaptable to various bottle shapes, sizes, and product viscosities.

- Hygienic design: Suitable for cleanroom and sanitary environments, especially in food and pharma sectors.

- Minimal staffing: A fully automated line significantly reduces the number of operators required, lowering labor costs and minimizing human error.

What Are the Different Types of Bottling Machines?

There are several categories of bottling machines based on filling mechanism and product type:

- Volumetric Fillers: Ideal for applications requiring precise volume control, common in beverage and cosmetic sectors.

- Net Weight Fillers: Used for high-value or abrasive liquids where accuracy is critical, often in chemicals and oils.

- Piston Fillers: Best for viscous products like sauces, gels, or creams.

- Monoblock Machines: Integrate filling, capping, and sometimes labeling in a compact footprint-excellent for space-constrained lines.

Our Bottling Machines

- Automated Liquid Filling Machines

- Automatic Powder Filling Machines

- Automatic Solid Filling Machines

- Automated Bottle Capping Machines

- Automatic Conduction Sealing Machines

- Automatic Labelling Machines

Frequently Asked Questions (FAQs)

Why choose Shemesh Automation for my automation needs?

With decades of experience and a global reputation for excellence, Shemesh Automation delivers reliable, high-performance bottling machines tailored to your needs. Our equipment is built to last, with a focus on efficiency, hygiene, and integration.

What warranties and after-sales support will I receive?

All Shemesh machinery comes with a standard warranty and access to our worldwide after-sales support network. We provide on-site training, remote assistance, spare parts, and maintenance plans to keep your lines running smoothly.

Can Shemesh customise a machine for my factory’s specific needs?

Absolutely. Our engineering team works closely with you to design and adapt machines to your specific production requirements, floor plans, and product specifications.

Follow us on LinkedIn for more updates on our latest bottling, capping, labeling, and packaging innovations.