If you have ever embarked on the process of fully automating your labelling process with automatic wraparound labelling machines, you will know there is a wide range of systems and solutions to choose from.

Most commonly though, if you are looking to wrap a label around the full or partial circumference of your product, there are two leading tried and tested methods: Linear wraparound labelling machines and three-roller wraparound labelling machines.

The choice between the two, essentially boils down to two main factors:

- The desired speed of your automatic wraparound labelling machine.

- Your container range which will reflect on changeover parts and operational flexibility.

- Label overlap (Y/N), and accuracy requirements related with overlapping.

Three-Rollers Automatic Wraparound Labelling Machines

Shemesh Automation offers LWA automatic wraparound labelling machines utilizing either the three rollers methodology or the linear side conveyor methodology, depending on the specific needs of the client.

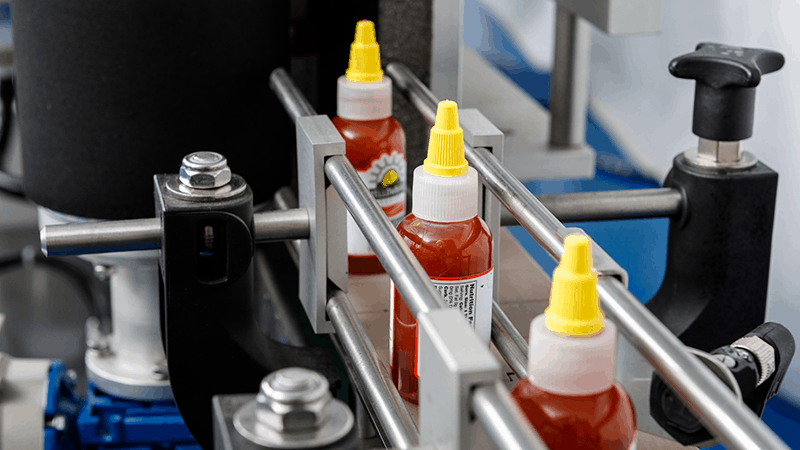

The Shemesh three rollers methodology, uses a HERMA H500 rotary servo-driven applicator head to ensure an accuracy of up to one-third millimeter on the edge of the peeling plate. The HERMA H500 applicator applies the leading edge of the label on to cylindrical shaped products, while the bottle is held by the three rollers mechanism.

The three rollers enclose the container to ensure it does not move relatively to its vertical axis, eliminating inconsistencies related with container manufacturing. One of the three roller rotates the container so that the label is applied accurately.

The name of the game when it comes to the three-rollers methodology is accuracy. Whilst still being no slouch, offering speeds of up to 60 ppm depending on container, required orientations and label size comes into its own when applying labels to containers made of less robust materials for example, lower-cost glass or plastic.

Because the Shemesh three-rollers mechanism holds the product in place while stretching the label as it is applied, creases and bubbling are eliminated and positional accuracy is significantly increased.

You can watch a video of our LWA automatic wraparound labelling machine utilizing the three rollers methodology here

Linear Side-Conveyor Automatic Wraparound Labelling Machines

If you are looking for higher-speed wraparound labelling (anything above 35ppm), the Shemesh side-conveyor methodology LWA automatic wraparound labelling machine is ideally suited to your needs.

First, containers progress along the LWA wraparound labelling machine to a star wheel separator for an accurate, high-speed feed and registration before arriving to the labelling zone.

Here, a sidebelt conveyor and a counter plate combine to positively rotate the container as it leaves the HERMA H500 Applicator with the label adhered at its first point of contact. Because the container never stops moving forward using this methodology, production speeds can be much higher. However, because the container is only secured on two surfaces, packaging materials quality plays a role with maintaining labelling accuracy.

You can watch a video of our LWA automatic wraparound labelling machine utilising the linear side rollers methodology here

Limitless Labelling Options

While the above two methodologies primarily refer to cylindrical containers requiring full wraparound labelling, there are limitless labelling possibilities within the range. The Shemesh LWA Series includes:

LWA Automatic Front and Back Labelling Machine: Capable of applying any type of self-adhesive label e.g. P, PE, opaque, transparent, paper, etc to the front and/or back of most common container shapes and sizes.

LWA Automatic Universal Labelling Machine: Capable of applying wraparound, top, front and/or back, side, bottom and even tamper proof labels to most common container shapes and sizes.

CAROLUS Automatic labelling machine for buckets: A fully-automatic wraparound labelling machine for buckets with automatic handle lifting and orientation.

You can download our complete labelling solutions brochure here. For more information or for a quotation for your line, please contact us today