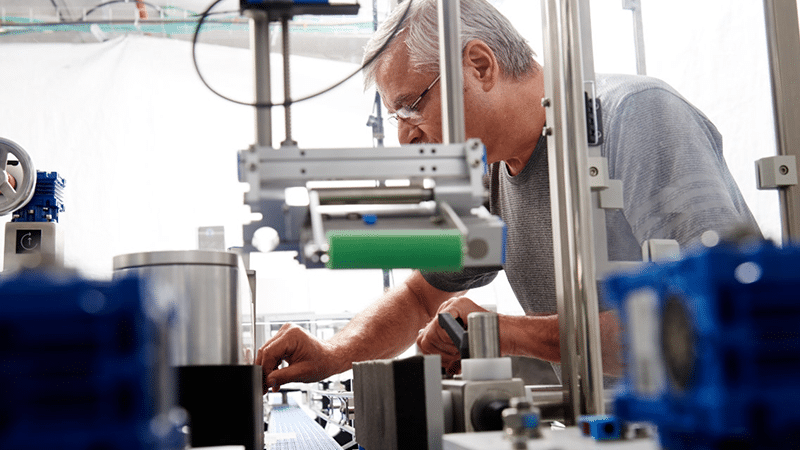

With so much innovation happening in the packaging machinery sector on an almost daily basis, it’s easy to forget that one of the most effective ways to increase your machinery ROI is to implement a robust preventative maintenance (PM) routine.

Successful preventative maintenance incorporates a regular program of inspections, cleaning, testing, and repairs designed to keep your machinery in good working order and prevent unexpected breakdowns. The goal of preventive maintenance is to identify and fix potential problems before they cause significant damage, thus increasing the lifespan of the machinery and ensuring consistent, high-quality production.

This can be achieved through regular checks of your equipment’s key components, such as motors, bearings, and gears, as well as thorough cleaning and lubrication.

Performing preventive maintenance on a regular basis can increase the overall ROI of your packaging machinery by reducing the risk of unexpected downtime, lowering operating costs, and improving the efficiency and productivity of the machines.

If you need convincing that preventative maintenance is worth your time, here’s 10 key benefits that can be unlocked by the implementation of an effective preventative maintenance regime:

1. Increased Equipment Life: Preventive maintenance helps to identify and fix potential problems before they cause significant damage, thereby increasing the lifespan of your machinery. Quick Tip: Regularly checking chain conveyors for fractures will allow you to quickly replace individual chains rather than suffering extended downtime and cost if the problem worsens and you need to change the entire set.

2. Improved Equipment Performance: Regular maintenance ensures that your machines are functioning at their best, reducing downtime and increasing productivity. In many cases unscheduled maintenance downtime will cost more in lost productivity than the price of investing in a preventative maintenance routine. Food for thought. Quick Tip: Air leaks can reduce the performance of your filling machine pistons, eventually resulting in a lower throughput. Listen in, every now and again, to check for any audible leaking air so that you can quickly fix the piston before suffering a reduction in overall performance.

3. Lower Operating Costs: By keeping machinery in good working order, you can reduce energy costs, avoid costly repairs, and minimize downtime. Having a clear idea of your spare parts requirements over a lengthy period and keeping a sufficient supply in-house will save on expensive ad-hoc shipping costs and avert potential downtime due to parts unavailability. Quick Tip: Avoid having to install an unscheduled replacement conveyor belt and suffer the associated downtime by regularly checking that your belts haven’t moved off-centre – which will cause belt degradation over time.

4. Improved Safety: Regular maintenance helps identify and repair potential safety hazards, reducing the risk of accidents in the workplace.

5. Better Quality Control: Preventive maintenance helps ensure that your machines are producing high-quality products, reducing the risk of defects and customer complaints.

6. Increased Uptime: Scheduling preventive maintenance during scheduled downtime can help you avoid unexpected shutdowns, reducing the amount of lost production time. Quick tip: If you make a product changeover in a scheduled maintenance period, double check that your butterfly clips are securely tightened before restarting the line.

7. Improved Maintenance Planning: A well-planned preventive maintenance program helps you prioritize and schedule maintenance tasks, making it easier to manage your maintenance budget. Quick tip: Factor in time for treating any parts that are vulnerable to rusting, such as bearings etc to increase their longevity and reduce downtime.

8. Better Compliance with Regulations: Preventive maintenance helps you ensure that your machinery is in compliance with safety and environmental regulations.

9. Enhanced Reputation: Consistently producing high-quality products on time, and in quantities that always meet demand, demonstrates your commitment to customer satisfaction and helps improve your company’s reputation.

10. Better Data Collection: Regular maintenance provides an opportunity to gather data and insights into the performance of your machinery, which can inform future improvements to your equipment and processes.

If you need advice on how to implement a preventative maintenance schedule on for your packaging line, or if you require service, spare parts or brand new machinery, don’t hesitate to contact the Shemesh Automation team.

Whether you are looking for a complete turnkey packaging line – from product feeding and filling all the way to case packing and palletizing, or single high ROI packaging machines, you can rest assured that all Shemesh machinery is offered with a full recommended spare parts inventory, Line integration, installation and training support.