Automatic Powder Filling Machines

Powder Filling Machines

What is a Powder Filling Machine?

Automatic powder filling machines are essential in packaging operations across the food, cosmetics, and chemicals. These systems ensure hygiene, speed, and accuracy when filling both rigid containers and flexible bags.

How Does a Powder Filling Machine Work?

Automatic powder filling machines operate using volumetric or gravimetric principles. Powders are stored in a hopper and dispensed via augers, vibration funnels, or multi-head weighers. Machines for rigid containers typically use rotary indexing systems, while flexible pouch fillers integrate bag opening, dosing, sealing, and nitrogen flushing in one monoblock unit.

What Are the Benefits of an Efficient Powder Filling Machine?

- Fast, repeatable operation for high-output production

- Accurate dosing with minimal waste

- Low maintenance through robust mechanical design

- Quick changeovers for multiple SKUs or formats

- Compliance with ATEX, GMP, or hygienic production standards

What Are the Different Types of Powder Filling Machine?

- Auger Fillers – Ideal for fine powders using screw-based dosing

- Multi-head Weighers – High-speed and accurate for granulated or irregular powders

- Volumetric Cup Fillers – Suitable for free-flowing powders

- Net Weigh Fillers – Used where strict weight precision is required

- Vacuum/Air-Fill Systems – Designed for lightweight or fluffy powders

Our Powder Filling Machines

Solifill Rotary Multi-Head Weigher Filling Machine

Explore Solifill →

The Solifill is a rotary powder filling machine for rigid containers such as tubs, jars, and bottles. With integrated multi-head weighers, it offers speed and precision across the food, cosmetics, and chemical sectors. Solifill integrates seamlessly with cappers, sealers, and case packing systems for a complete line.

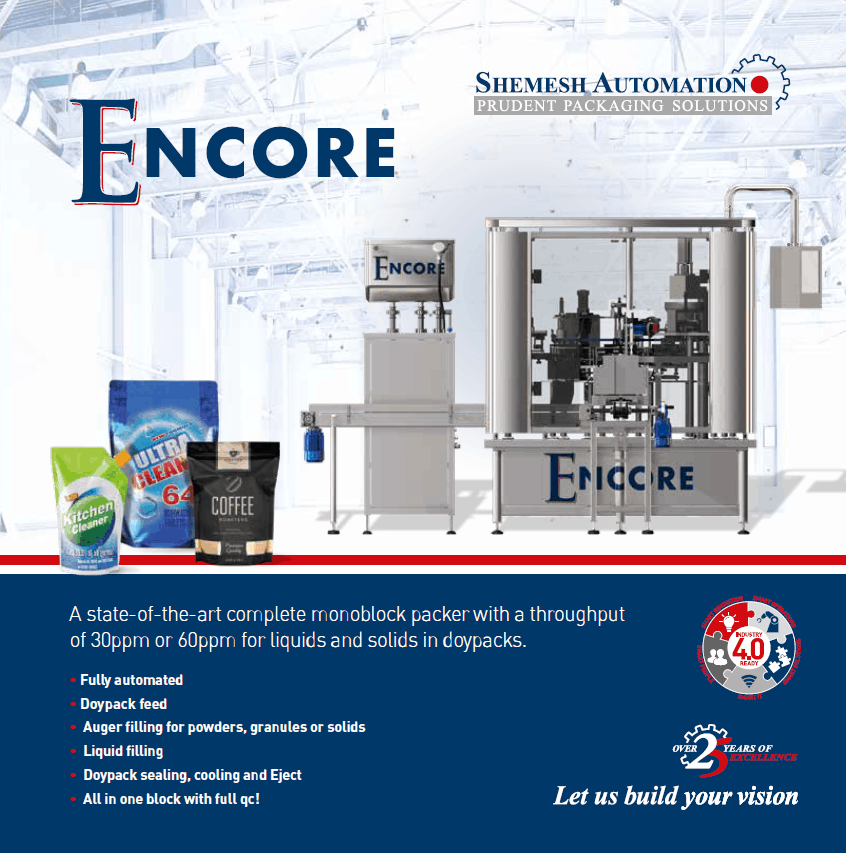

Encore Monoblock Rotary Filler for Flexible Bags

Explore Encore →

The Encore is a monoblock rotary solution for filling powders into flexible bags or pre-made pouches. It performs bag opening, servo-controlled dosing, sealing, and optional nitrogen flushing—all in one compact footprint. It’s ideal for co-packers and flexible packaging operations using automatic powder filling machines.

Custom Powder Filling Solutions

Need a tailored system? Our engineering team builds custom automatic powder filling machines adapted to your product, production space, and container type. We also offer ATEX-compliant versions and integration with quality control, labeling, and case packing.

Frequently Asked Questions (FAQs)

Why choose Shemesh Automation for my automation needs?

Shemesh Automation brings over 30 years of experience delivering smart, integrated packaging solutions—trusted by leading global brands.

What warranties and after-sales support will I receive?

We offer a 12-month warranty (extendable), lifetime remote support, spare parts availability, and local service via our hubs in the US, UK, and EU.

Can Shemesh Automation customize a machine for my factory’s specific needs?

Yes. Every Shemesh Automation machine and packaging line can be tailored to your product specifications and factory layout—ensuring a perfect fit with your production requirements, space constraints, and operational goals.

Get in Touch

For more information on the Filling Machines, contact us today to discuss how we can meet your unique packaging requirements.

Follow us on LinkedIn for updates on our latest innovations.