Case Study – Sano-Bruno’s Enterprises

Optimising chemical packaging line with Shemesh Automation.

Overview

Sano-Bruno’s Enterprises is a market leader in home cleaning products with 400+ SKUs. To streamline operations and reduce waste, Sano partnered with Shemesh Automation to deploy a high-end, fully integrated packaging line that handles 10+ products, including angle-neck bottles and multiple cap types, while maintaining speed, precision and hygiene.

The Challenge

- – Run 10+ SKUs on one line, including slanted-neck bottles

- – Support screw caps, pump dispensers and trigger sprayers

- – Reduce downtime and filling waste at scale

- – Maintain hygiene, safety and compliance

The Shemesh Packaging Line

- FGW60 Automatic Gear Pump Filler – up to 60 products/min, ±3 ml accuracy, anti-overflow, anti-drip, CIP, Industry 4.0 ready

- ATTILUS Continuous Robotic Capper – up to 50 products/min per head, servo torque ±5%, fast tool-less changeovers

- Front & End Modules – bottle descrambler or robotic feeder, automatic conduction sealing machine, fully automatic labeller, automatic form-fill-seal case packer, robotic palletiser

Machines & Close-ups

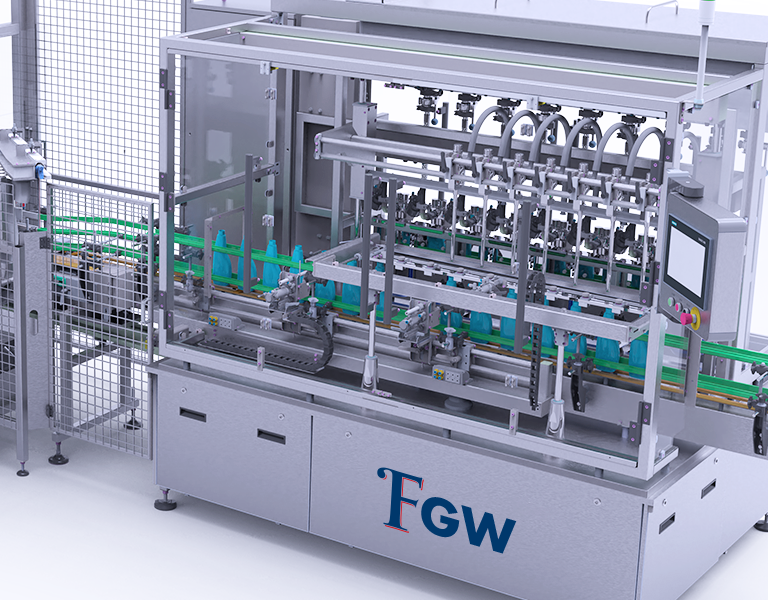

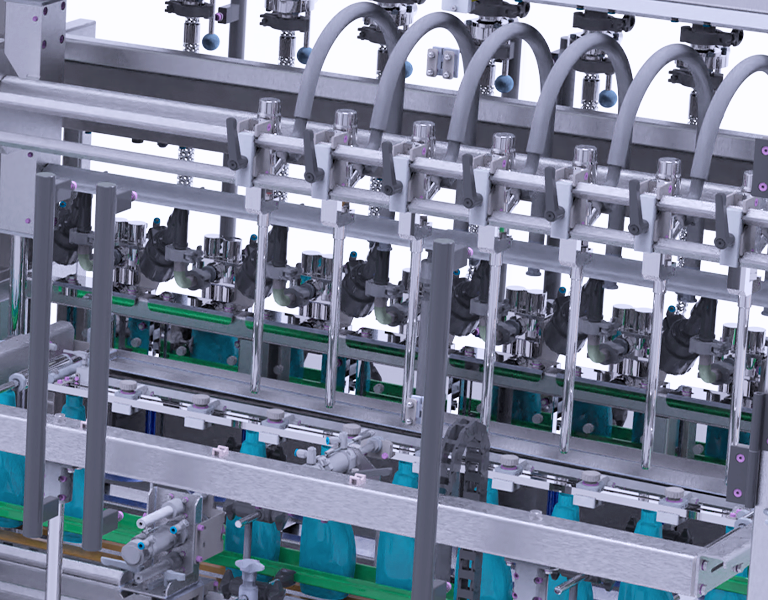

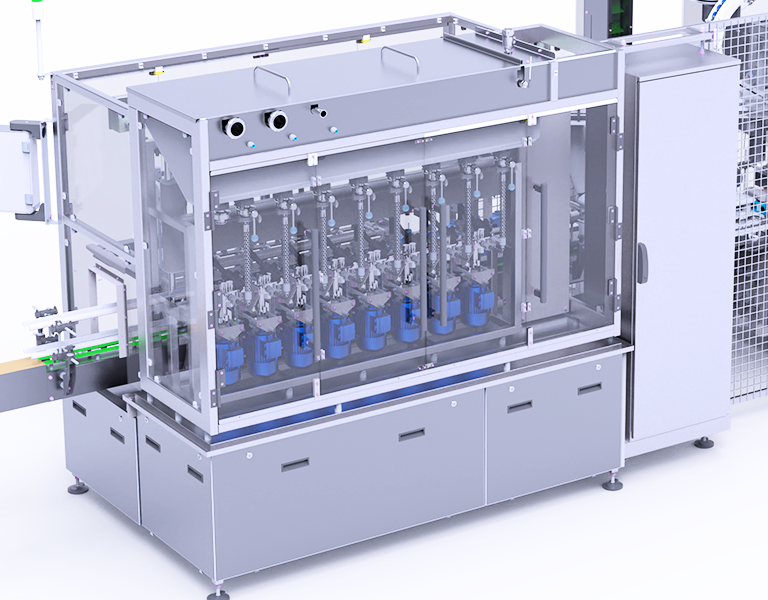

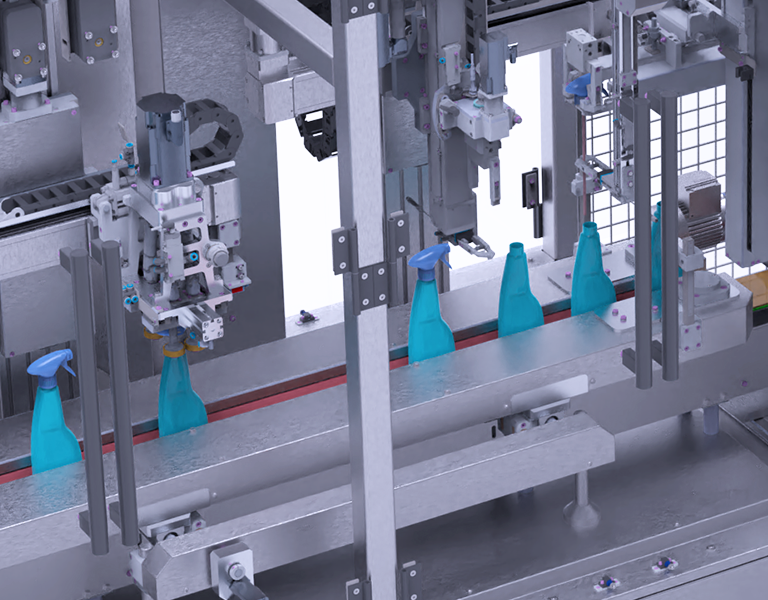

FGW60 Automatic Gear Pump Liquid Filling Machine

- – ±3 ml portioning tolerance for waste reduction

- – Proprietary anti-overflow and no-drip screwless showerhead nozzles

- – Supports oval, conic, round and rectangular canisters

- – Built-in CIP; explosion-proof and corrosion-proof upgrades available

- – All liquid-contact metals in SS316; SS304 elsewhere

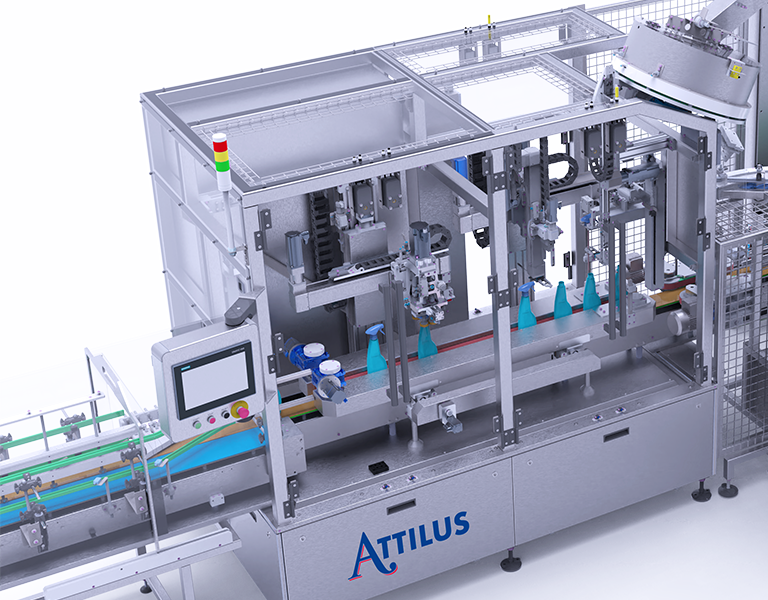

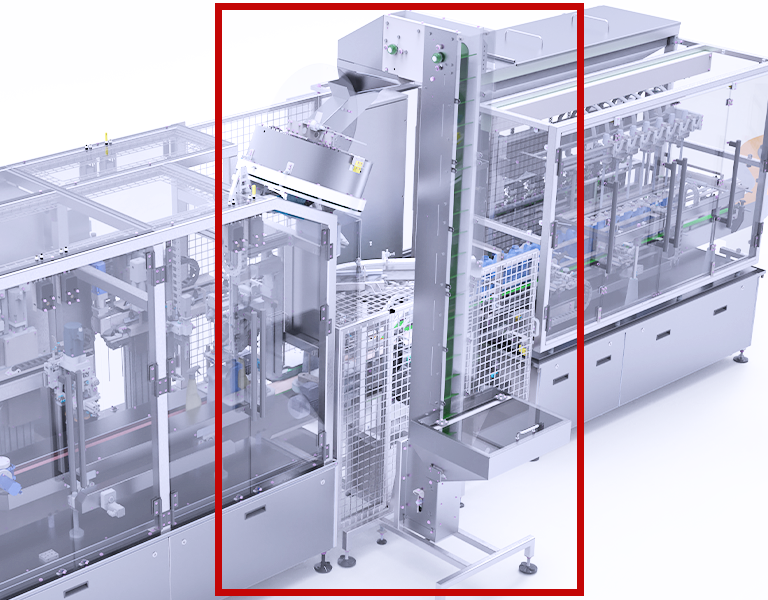

ATTILUS Continuous Robotic Trigger, Pump & Screw Capper

- – Up to 50 products/min per capping head

- – Tool-less format changeover under 20 minutes (manual) or under 5 minutes (servo)

- – Handles trigger, pump and screw caps

Comparative Results

| Criteria | Before Shemesh | After Shemesh |

|---|---|---|

| Production Efficiency | Frequent downtime and manual adjustments | 60 prod/min (filler) and 50/min (capper per head) with continuous flow |

| Waste Control | High variability in filling volume | ±3 ml accuracy with anti-drip and anti-overflow mechanisms |

| Flexibility | Separate machines needed for different products, limited adaptability | One line handles 10+ SKUs with multiple bottle shapes and cap types |

| Quality Consistency | Inconsistent torque and sealing | Servo torque ±5% ensures consistent capping quality |

| Hygiene & Safety | Basic compliance only | Sanitary design with SS304/316, CIP, explosion/corrosion-proof options |

| Scalability | Manual systems that are hard to upgrade | Industry 4.0 ready, modular architecture and robotic integration |

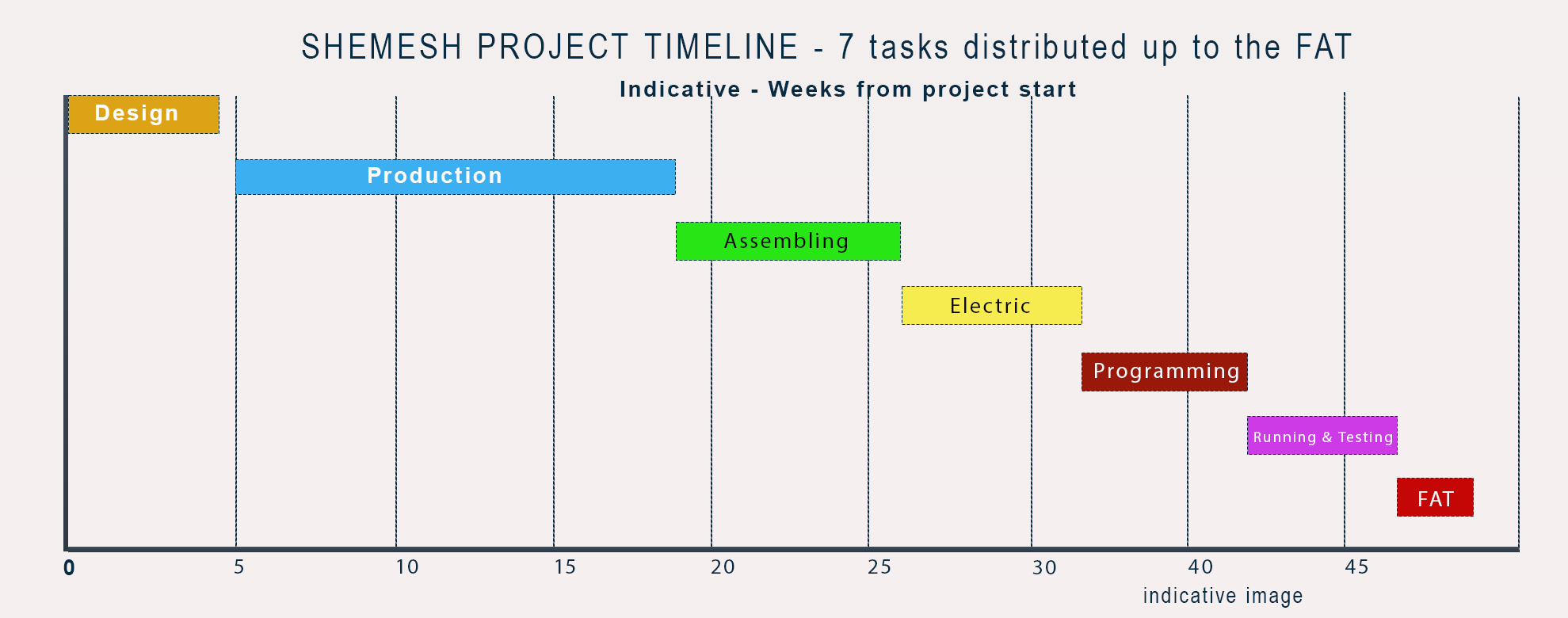

Indicative Project Timeline

Measurable Impact

- – Higher throughput with fewer stoppages

- – Reduced product giveaway and scrap through precise dosing

- – Faster SKU changeover on one versatile line

- – Improved and consistent capping quality

- – Future-ready digital connectivity and remote diagnostics