Shemesh’s ASTERRA and ATTILUS machines were highlighted in this PPMA Total Show preview article published in the September-October edition of Machinery Update. You can read the full piece here (pg 76).

Filling and capping units will showcase advantages

Visitors to the Shemesh Automation stand at the PPMA Total Show this year can discuss the latest developments from the company: one in filling and one in capping.

For instance, the latest ASTERRA mechanical cam rotary piston liquid filling machine is a robust and versatile machine designed to deliver high performance.

“The machine is a positive displacement, high-technology based, small footprint, low utilities, sustainable solution,” says marketing director at Shemesh, Roni Levi.

ASTERRA is equipped with cam driven filling stations each featuring a state-of-the-art SA nozzle proprietary design to fill your product with near zero leaks, splashes, bubbles, or overflow with ultra-high accuracy of+/- 2ml of filling volume.

It can handle containers of most common shapes and sizes in the food & beverage, chemicals and cosmetics industries. It is suitable for low viscous products as fruit juices as well as high viscous products, with or without solids such as goulash, paté, sauces, pastes, tomatoes, honey, puree and jams.

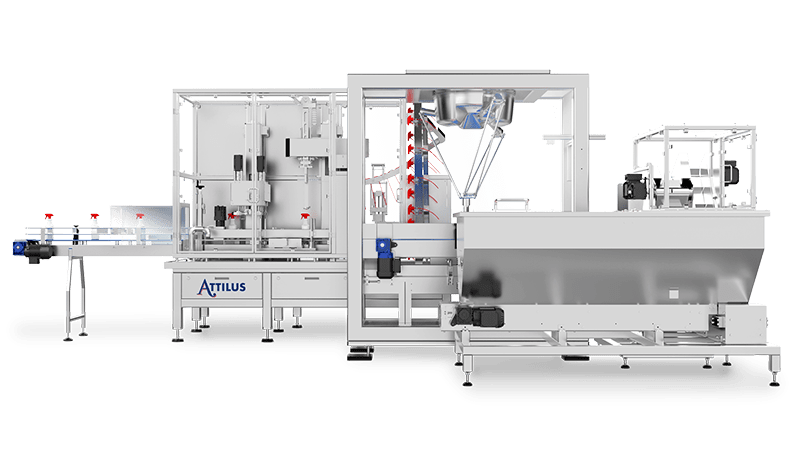

The company can also discuss the new ATTILUS continuous motion trigger, pump and screw capper that operates at up to 80 packs per minute with show visitors to its stand.

Shemesh says the ATTILUS capping machine enables higher speeds and enhanced accuracy in automatic caps, pumps and triggers sorting.

A Robotic Sorter based on Delta Robot and an advanced vision system allows the ATTILUS to sort and orientate caps from the most complex screw tops to trigger and pump caps.

Also, the capper utilises a pick & place Cartesian Robotic Arm (gantry two axis robot), which is servo-controlled, to track and deliver the caps to the bottles while in motion, ensuring smoother and faster production.

You can read the original article, which was published in September 2022 here (pg76)