Our new net-weight liquid filling machine, FALCON made the news in the August edition of Innovations in Food Processing & Packaging magazine. You can read the full piece on pg 7 here.

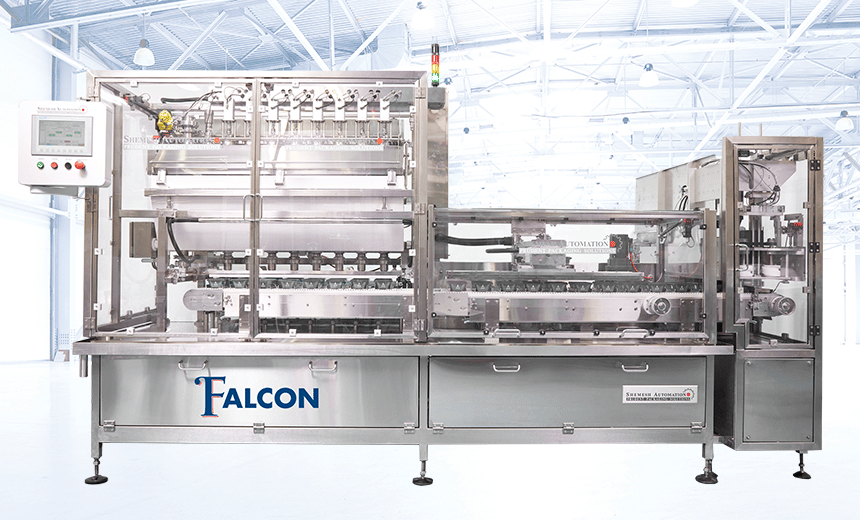

Shemesh launches the “Falcon” – Net weight liquid filling machine for thin liquids featuring hot fill of viscous and abrasive materials

Viscous and abrasive materials present some of the most challenging applications for filling machines. But now there is a brand-new solution on the market that can handle the toughest products: the new and unique Falcon, a high-speed net weight filler from Shemesh Automation, is a game changer.

Incorporating the Shemesh Deenex denester as well as a unique parallel servo-drivenindexing conveyor for maximizing throughput potential, the innovative Falcon offers many benefits that can increase efficiency levels significantly. It has been developed primarily to target the chemical sector. However, the creative design also makes it suitable for filling food, such as tubs of tahini and hummus.

Shemesh has applied decades of engineering expertise to combine a unique sequence of technologies that can load, sort, fill and package a variety of cleaning agents, creams and pastes. Using gravity or other positive displacement methods of filling ensures almost pin-point net weight accuracy. There are many materials that are sensitive to specific gravity changes due to temperature and this new filling will accurately control the net weight to help manufacturers comply with legislation.

Shemesh’s VP Global Sales & Business Development, Yonatan Levy, says the Falcon is built for long-term durability, avoiding the common problem of degradation of machine parts by harsh materials.

He explained: “This machine was built to handle the toughest materials out there. What sets it apart from its competitors is its parallel infeed system, which is used to maximise the throughput from the denester. The Falcon filler handles problematic materials seamlessly and accurately.

The tank and nozzles design guarantees that the liquid path is free from any kind of mechanical parts such as pistons and seals which can suffer from wear and tear because of the abrasiveness of certain materials.”

Shemesh’s Falcon PLC and HMI controls both the filler and the denester which essentially creates a single combined unit. The Falcon is also easily and rapidly adjustable. All parts are tool-less for quicker changeover, and manufactured from high grade, robust stainless steel. Changeover times are less than 15 minutes – a massive benefit for more niche producers switching between product lines more frequently.

Optional features from Shemesh include an agitator and a double jacket heated liquid tank and heated nozzles at set temperatures of up to 95˚ which allows materials that must stay at a certain temperature to remain liquified through the packing process. Full CIP automatically controlled from the HMI is another option for all Shemesh fillers, the Falcon included.

Customers are able to order an entire solution, a single non-stop line that accommodates the most challenging abrasive liquids from product feed to packaging. Shemesh’s electrical, mechanical and control systems are all completely integrated to maximize productivity and minimize downtime.

Flexibility, accuracy and speed are key to packaging efficiency for every material that is sold by weight. The Falcon net weight filler can be customised to suit many types of filling methods. For example, it can be designed to include more or less filling stations, weighing or load cells for each platform.

Positioned right under the nozzles, a blister pack for example will be sitting on top of the load cell to establish the weight. Once it hits the target weight it stops automatically with the accuracy of plus or minus 0.2% (by weight). This means that every filling station can be controlled independently as each has its own load cell.

Yonatan Levy added: “Shemesh has for decades been a market leader particularly in cosmetics, food and beverage and chemicals sectors. We are dedicated to using our R&D strength and unrivalled experience to extend our product range into new and innovative areas, solving problems for our customers and, in turn, their own customers. The state-of-the-art functionality of Falcon is the latest testament to that strategy and we’re delighted to introduce it to our current and prospective customers across the world.”

Shemesh Automation boasts a broad portfolio of in-house manufactured mechanical and robotic based unscramblers, fillers, cappers, conduction sealers, labellers and case packers. Its robotics division also offers cutting-edge palletizing solutions and unique robotic sorting systems.

This is complemented perfectly by a tried and tested range of third-party machinery which allows the company to provide the perfect solution to meet customer needs each and every time. Its product portfolio is supported by a global aftersales team and a host of experienced project managers.

It is Shemesh’s mission to ensure customer satisfaction with every installation. Its turnkey “Total Solution” approach to packaging machinery offers its customers complete peace of mind as the line design, machine specifications, mechanical and software integration and QC aspects are all seamlessly managed by its expert teams.

You can read the original article, which was published in August 2022 here (pg7)