This article was originally posted in the PPMA.

Shemesh has launched a new mechanical cam-based rotary piston filling machine for high and low viscous products. This introduction follows five years of R&D and achieves a filling tolerance of +/- 2 ml and speeds of up to 300 containers per minute (higher throughputs are available depending on the number of filling stations).

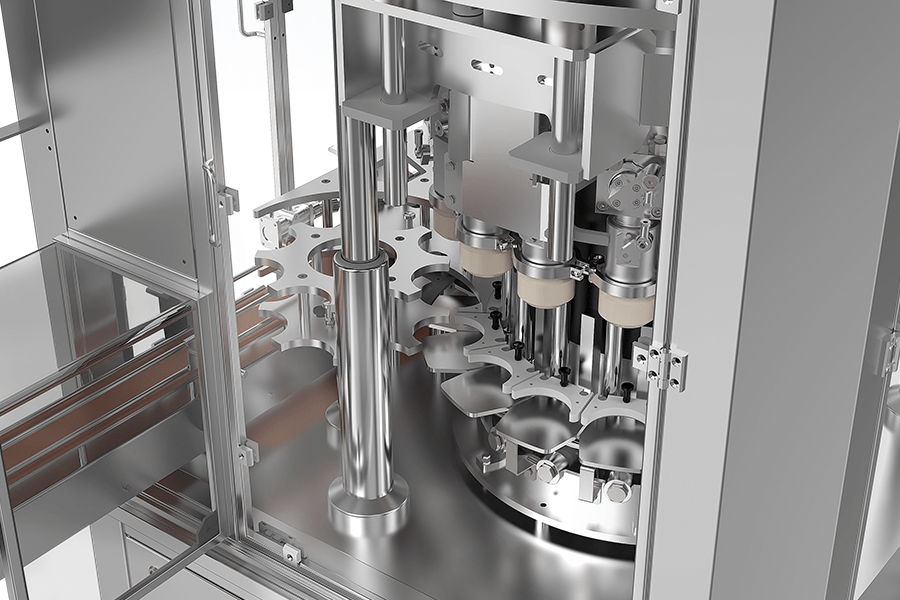

Called the Asterra, this new option includes 16 filling stations specifically designed to fill a wide range of low and high viscous liquid with particulates (viscosities from 500 to 400,000 CPS).

It is suitable for a wide range of products across varied market sectors including food & beverage, nonwovens, cosmetics, chemicals and household products.

The robust Asterra features a proprietary mechanical cam with built-in bottom-up Shemesh nozzles and portioning technology.

It also includes a programmable portioning speed graph for anti-foaming and drip prevention.

Shemesh says the Asterra’s technology results in higher accuracy as the filling process itself does not depend on auxiliary air pressure, which may be unstable. Additionally, the portioning process is faster and more consistent with this filling method which results in less waste and spillage.

Thanks to its proprietary nozzles and mechanical cam technology, Asterra can also fill highly viscous liquids, including particulates such as sauces with fruit pieces inside, peanut butter and pastes, etc.

Constructed of 304/316L stainless steel and USDA/FDA approved materials and sanitary welds, the Asterra is an hygienic option.

Meanwhile, the tri-clamp sanitary nozzle connections are designed for quick clean-up and maintenance, a ‘tool-less’ cam mounting system saves valuable time when changing production and/or product specifications and a complete changeover takes just 30 minutes.

This filling machine comes as a stand-alone filler or either in a rinser-filler-capper monoblock or in a filler-capper monoblock configuration. Asterra can also be easily incorporated as part of the complete Shemesh custom-made bottling line featuring unscramblers, rinsing machines, loading systems, cappers, sealers, labellers, case packers, palletisers and depalletisers.

The new filler has a small footprint; 4.9 ft x 5.2 ft only (1500 mm x 1600 mm excluding infeed and outfeed conveyors). That is thanks to the faster portioning process which means fewer filling stations and smaller turrets are required.

From water, peanut butter and ink, to pastes, creams and paints, our automatic liquid filling machines are designed to fill a wide range of liquids and particles with a broad spectrum of viscosity levels.