Thanks to Packaging World for publishing the following piece about our ATTILUS Continuous Motion Capping Machine. You can read the full piece here:

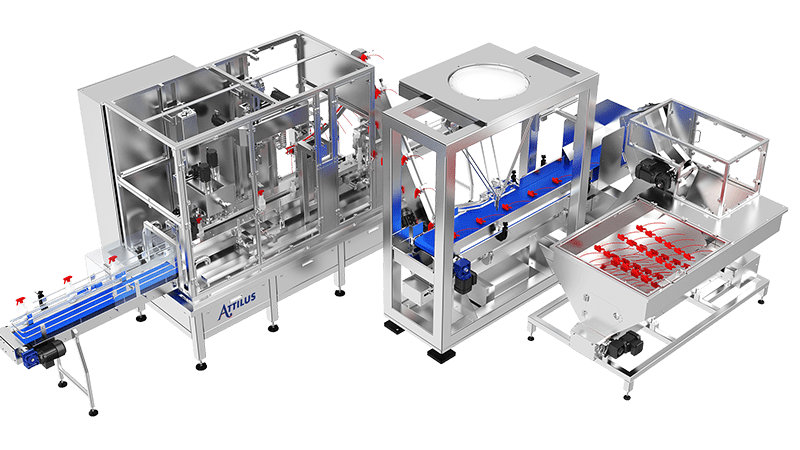

Continuous Motion Capping Machine

Shemesh’s Attilus continuous motion capping machine is designed to sort and orientate caps from screw tops to trigger and pump caps. It features a robotic sorter based on a delta robot and an advanced vision system.

Set for launch in September 2022, Shemesh’s Attilus capping machine utilizes a pick & place cartesian robotic arm (gantry two axis robot), which is servo-controlled, to track and deliver the caps to the bottles while in motion, ensuring smoother and faster production.

ATTILUS Continuous Motion Capping Machine

The Attilus operates at up to 80 ppm and includes bottle tracking and a synchronized gantry robot based on encoders and servos. Its integrated Siemens/AB PLC & HMI puts the operator in complete control, allowing simple programming – changing formats and course of movement at the touch of a button. The robotic enhancement of the Attilus also ensures changeover downtime is kept to a minimum (under 20 minutes).

The standard Attilus features include Servo controlled torque QC and cap position QC, as well as an array of optional features such as: vision QC system for cap position, fully automatic servo-controlled changeover which translates to under 5 mins changeover time and eliminates operators’ interventions and human error, bottle orientation for inclined neck bottles and ATEX/EX Compliance

The Attilus includes the following standard specifications:

• Industry 4.0 ready

• Minimal changeover time

• Tool free changeovers

• Festo pneumatics and Servo systems

• Complete SST304/316L design

• Siemens HMI & S7-1500 PLC series (Allen Bradley – optional)

• Banner/ Sick/Omron sensors

• E-stop buttons and safety interlocks wired through CAT IV safety controller.

• CE, ANSI, OSHA, NFPA and NEC compliant

• ABB Delta Robot

• SEW/Siemens Motors

• Cognex Vision Systems

This article was originally published on PackagingWorld.com (June 2022)