Packaging Insights published the following piece about Shemesh’s complete robotics-enhanced bottling line for cosmetics products with the aim of reducing downtime, lowering expenses, and preventing the complexities of integrating machinery. You can read the original article here.

“Quiet revolution”: Shemesh Automation harnesses robotics with A-Z turnkey packaging line for cosmetics

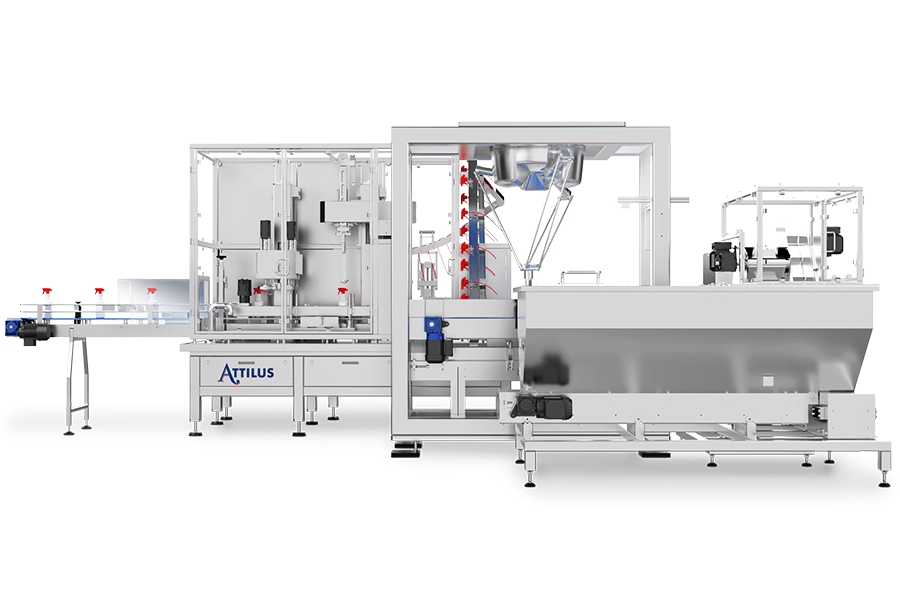

Automated packaging solutions provider Shemesh Automation is introducing the TKS-C60 for cosmetics manufacturing. The new line is built to handle the entire production process – feeding, filling, sealing, capping, labeling, case packing and palletizing cosmetics products of all shapes and sizes.

The TKS-C60 is engineered to operate across a broad range of cosmetics products, from creams and foundations to fragrances and nail polish, at a rate of 60 bottles per minute.

The line consists of three ABB Delta Robots – one on the product unscrambling station, one for accurate multi-capping and one for case packing – as well as an integrated advanced vision system.

“The advantages of sourcing all of your cosmetics packaging machinery from one supplier are clear,” the company shares.

“When dealing with one supplier, you can ensure each machine in your line is built to cater to your specific product and footprint requirements. Installation and integration require downtime – relying on multiple suppliers to coordinate this on a schedule that suits you can be almost impossible.”

Shemesh’s TKS-C60 smart technology is described as a complete turnkey packaging solution for cosmetics. It thus maximizes productivity and minimizes downtime.

“Reduced downtime and economies of scale are the name of the game here, and opting for one single manufacturer to provide your entire line is one way to achieve it,” the company details.  TKS-C60 is engineered to operate across a broad range of cosmetics products.

TKS-C60 is engineered to operate across a broad range of cosmetics products.

Seamless cosmetics manufacturing

Manufactured from high-grade, robust stainless steel, the TKS-C60 applies two lanes as per need to pack different products on the same line by setting up the requisite recipes via a smart HMI screen. The linear rather than rotary feed means fewer parts for faster and easier changeovers and cleaning, Shemesh details.

The machine is automated to identify different cap types and puck loaders. Furthermore, the line’s automatic bottle unscrambler uses a spider robot to provide precise bottle orientation, covering a broad range of bottle types common in cosmetics.

The mechanical elements ensure no change parts are required when unscrambling multiple different bottle shapes resulting in lower downtime and reduction in format parts costs over time.

Additionally, after capping, the line provides a customizable labeling function. Robotic case form fills and seals with an efficient transition to the palletizer to help make cosmetics manufacture and packaging seamless.

Growth of robotics

Shemesh Automation asserts that robots and cobots are becoming a “must-have” addition to packaging lines. “Faced with a barrage of external pressures, from supply shortages to increased utility costs, manufacturers are looking for creative ways to gain an edge over the competition,” the company says.

“Robots can generally complete tasks faster and more efficiently than humans – allowing workers to be deployed on more skill-dependent tasks. Integrating robotics within packaging machinery, for example, can enhance accuracy and allow for a wider range of products to be handled by the same automated line – generating huge savings on change parts and manpower.”

The company enlists data from the World Robotics Industrial Robots report to illustrate that in 2021 alone, the number of robots working in factories grew by 10% globally to three million.

“There is a quiet revolution taking place in factories and production plants worldwide – the growth in adoption of robotics,” Shemesh says.

With the TKS-C60, a robotic sorter and servo-controlled robotic arm deliver higher speeds, enhanced accuracy and flexibility in capping, filling and labeling. Its synchronized gantry robot based on encoders and servos puts the operator in control, allowing simple programming – changing formats and course of movement at the touch of a button.

You can read the full article, published by Packaging Insights on 6th January 2023 here.