Thanks to Nutraceutical Business Review for publishing the following piece about our unique new Gummies Packaging Line. You can read the full piece here.

Shemesh launches unique new gummies line offering end-to-end solutions for all bottle shapes

Gummies and jellies are renowned in the food, supplements, and nutraceuticals sectors for being one of the most awkward, hard to handle products. But the growing market of sticky sweets and supplements has now met its match with the launch of a brand new, highly innovative 60 products per minute A-Z gummies packaging line from Shemesh Automation – the TKS-G60.

Shemesh has applied its decades of engineering expertise to seamlessly combine a unique sequence of technologies that feed, load, fill, cap and label bottles and gummies of all common sizes – and ultimately case pack and palletize them too. Shemesh Automation’s VP Global Sales & Business Development, Yonatan Levy, says Shemesh is the only machinery manufacturer in the world to provide an entire uninterrupted bottling line for gummies and jellies where all the core machinery in the line is made by just one manufacturer. This, in turn translates to no pointing fingers between different machinery makers when something goes wrong, as well as to one source – the original manufacturer – for after sales, service and support, a huge plus.

He explained: “It’s hugely beneficial for customers to be able to partner with a single manufacturer capable of meeting all their needs for gummy packaging from product feed to palletising. It saves them both time and money as they only have to deal with one supplier and one team of engineers who know their systems inside out. And of course our electrical, mechanical and control systems are all completely seamlessly integrated under one platform to maximise productivity and minimise downtime.”

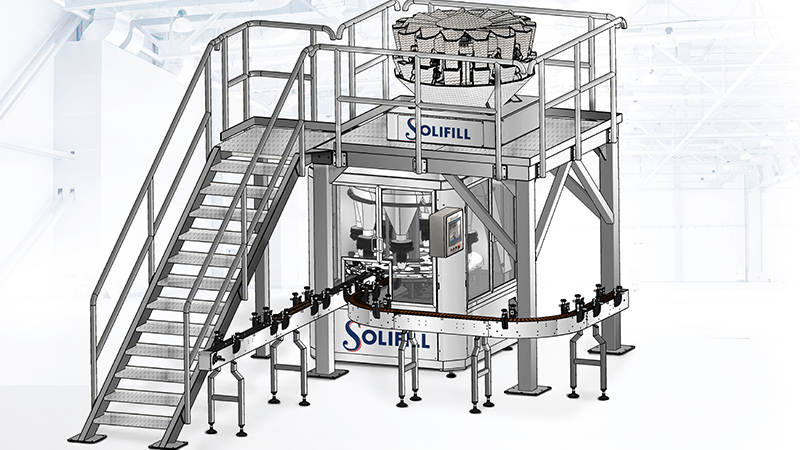

Flexibility is key in gummy packaging efficiency and the Shemesh line is headed up by an unscrambler that can be either mechanical where bottle choice is limited or robotic where multiple shapes and unlimited types of bottle are involved.

This feeds into a continuous rotary multi-head weigher based filling system which dispenses a predetermined fill weight of product to the continuous motion rotary base, transferring product into the customer’s rigid container / bottle / jar through a transfer funnel.

The bottles are fed through a timing screw into an infeed-starwheel which in turn feeds the main turret. Once in the main turret the combination scale filler is timed with the rotary platform to ensure accurate weight transfer. The product then travels onto a vibration section within the turret to allow for the transfer and settling of the entire dose into a narrow container/bottle opening.

Bottles are sealed using induction sealing which reduces oxygen and moisture thus improving shelf life – key for certain specialist supplements that don’t immediately fly off the shelves. The labeller can uniquely handle literally most common types of bottles that a co-packer may need – again a massive benefit for more niche producers switching between product lines more frequently.

In addition, there are QC points along the entirety of the line to ensure pinpoint accuracy and top quality all the way through. All the parts are tool-less for faster changeover, and manufactured from high grade, robust stainless steel. Furthermore, the stippled surface of the line in certain critical areas reduces the level of direct product contact and the chance of it sticking.

You can continue to read the rest of the article, which was published on 25/7/22 here