This article was originally posted in the International Fibre Journal.

Shemesh Automation, a global manufacturer of packaging machinery, has relaunched its space-saving, sustainable range of monoblock (monobloc) all-in-one packaging solutions dedicated to the nonwovens sector. The packaging leader will be highlighting its enhanced Monoblock machine series at IDEA22 in the Miami Beach Convention Center, March 28-31, 2022.

The Monoblock series from Shemesh Automation encompasses all aspects of downstream packaging from cans & wipes feeding, loading, dosing, and sealing through to capping, a full built-in QC, and smart weight checking.

Thanks to the maintenance-friendly design, operators have optimum accessibility of machine parts allowing for tool-less changeovers quickly and safely. In terms of sustainability, the monoblock machines save energy and allow the use of eco-friendly and recyclable packaging for better sustainability.

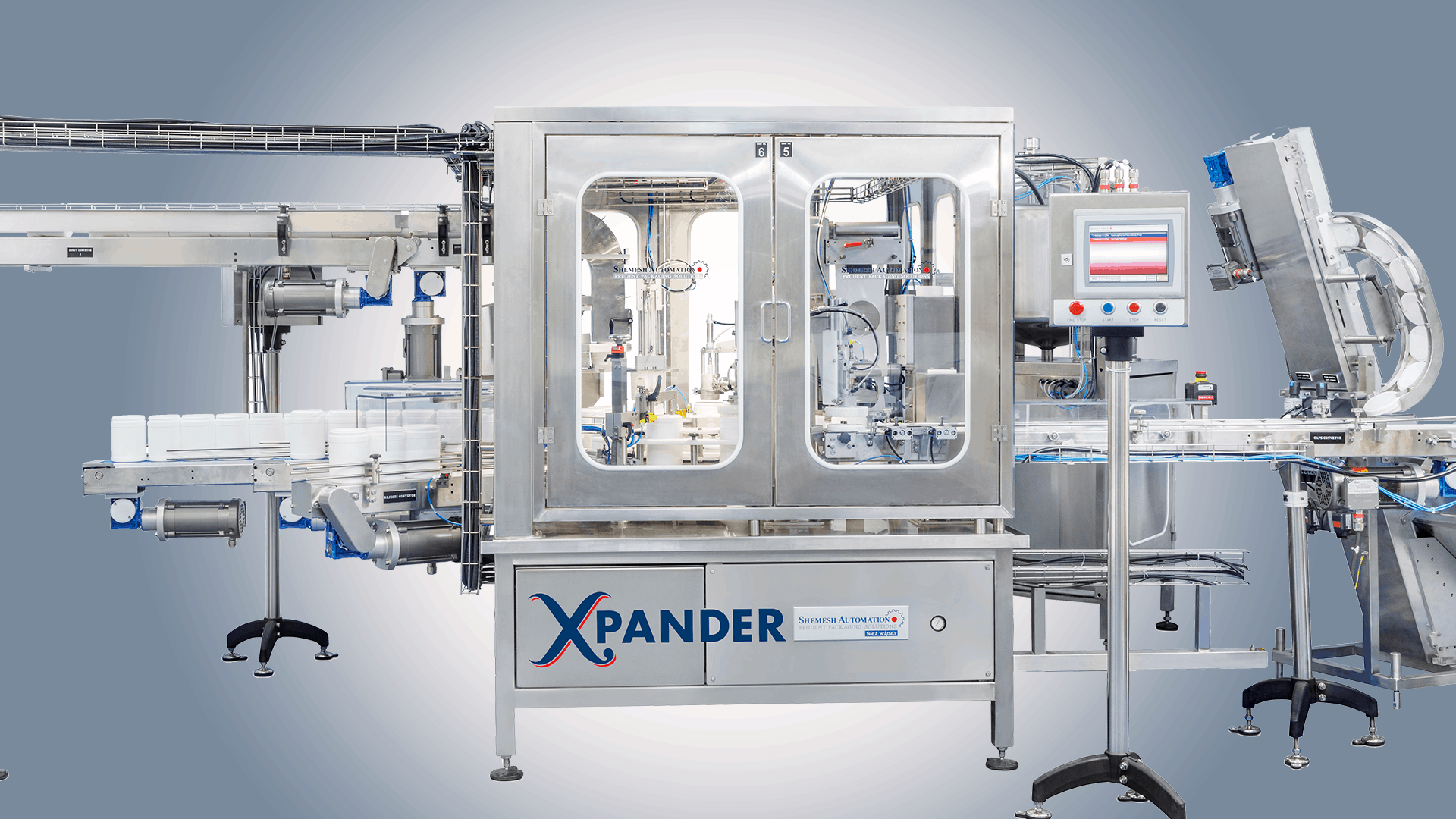

Taking center stage at the show will be the latest model Xpander+, a fully automatic all-in-one packaging machine with completely hands-free operation at a throughput of up to 35ppm. The Xpander+ is a fully integrated compact monoblock system (1850mm L x 1650mm W excluding inlet conveyors). This monoblock is equipped with a servo-driven pump system, height adjustable nozzles, and filling accuracy of +/-0.5% of liquid volume, eliminating spillage and therefore increasing production efficiency. Furthermore, the dosing station incorporates exchangeable nozzles and integrated CIP (Cleaning in Place) for greater clean configurations.

The Citadel-R (2241mm L x 3036mm W, with inlet conveyors!) and Citadel-J for jumbo size containers (3260mm L x 2270mm W, with inlet conveyors!) encompassing all aspects of round wipes downstream packaging, from bags/pouches feeding and roll stuffing to liquid filling and bag sealing with full built-in QC. The filling station is designed with total flexibility in mind to have an unlimited filling range, offering adjustable pump portioning.

The Citadel affords flexible and efficient operation and offers exceptional ROI while reducing waste, cutting production times, and maintaining high levels of product quality. In addition, it’s capable of operating in very compact spaces.

There’s even more to come, as Shemesh is now introducing its new machine, the Citadel-X, which is a very fast monoblock for this application. Currently, in final production, the Citadel-X is based on its Citadel forerunners and will deliver even more impressive speeds of 100-120 ppm all-in-one downstream packaging for dry and/or wet applications when packing up to 300ct rolls in stand-up-pouches.

Shemesh Automation CMO Art Malinowski concluded, “With our new Citadel models, we successfully identified a gap in the market by listening to our clients to deliver the complete packaging process of round wipes in doypacks. The new Citadel-X design, in particular, builds upon decades of Shemesh Automation’s proven expertise in different technologies, such as liquid filling, rolls stuffing, bag feed, bag opening, and conduction sealing. We’re looking forward to sharing this and other class-leading features with customers at IDEA22 in Miami.”

IDEA22 is a leading international event fully dedicated to the entire supply chain of the nonwovens and engineered fabrics industry. Shemesh Automation will be located in Area 900, Booth 4808.

Shemesh Automation boasts a series of unique all-in-one Monoblock Packaging Solutions, encompassing all aspects of downstream packaging including feeding, filling, capping, double-capping, weighing, labeling QC and discharging.