This article was originally featured on CHP Packer International.

Shemesh Automation has launched Asterra a robust, versatile high-end industry 4.0-ready pioneering positive displacement Rotary Piston Filler. It offers a filling tolerance of+/- 2ml and speeds of up to 300c.p.m.

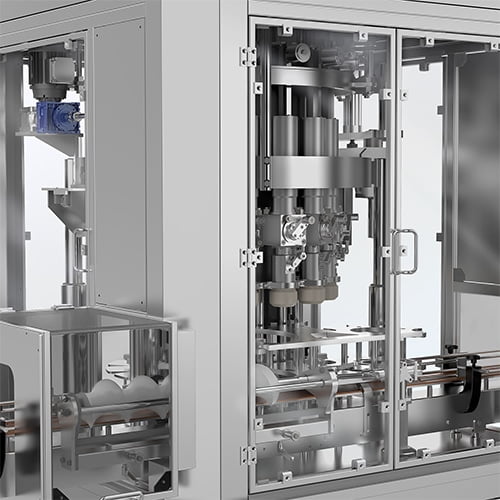

The Asterra includes 16 filling valves designed to fill a range of low and high viscous liquid with particulates (viscosities from 500 to 400.000 CPS).

The Asterra features a proprietary mechanical cam with built-in bottom-up Shemesh nozzles and portioning technology. And a programmable portioning speed graph for antifoaming and drip prevention.

Mechanical-cam based, technology also results in higher accuracy as the filling process does not depend on auxiliary air pressure, which may be unstable or sometimes liquid contaminated. Additionally, with this filling method, the portioning process is faster and more consistent.

Featuring SEW motors, this rotary filler is fully controlled by Siemens HMI and PLC unit Allen Bradley controls platform is also optional. Fill speed and portioning trajectory is adjusted simultaneously for all pistons via the touch panel. The interface software provides a wide range of functions, controls, monitoring and traceability for improved production efficiency.

This filler comes as a standalone unit or either in a rinser-filler-capper monobloc or in a filler-capper monobloc configuration.

The Asterra has a small footprint, 4.9ft x 5.2ft (1500mm x 1600mm excluding infeed and outfeed conveyors). That is thanks to the fact that the portioning process itself is much faster, which results in fewer filling stations and smaller turrets overall, saving space in your production plant.

From water, peanut butter and ink, to pastes, creams and paints, our automatic liquid filling machines are designed to fill a wide range of liquids and particles with a broad spectrum of viscosity levels.