Gallery

The World’s First Automated Conduction Sealing Machine With 100% Thermal Imaging Inspection Technology

For the first time in the industry, Shemesh Automation presents the SealPro Total Automatic Conduction Sealing Machine – and here’s what the ‘total’ stands for:

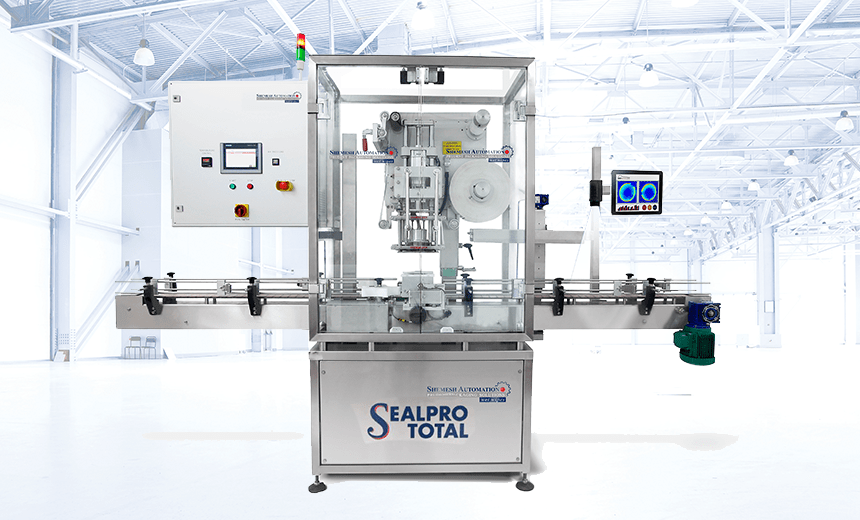

The Sealpro Total Automatic Conduction Sealing Machine is the first 100% in-line inspection system for heat sealed packages that is non-intrusive and does not result in production slowdown.

This represents a quantum leap forward from sampling to monitoring every single package in real time. The system’s live analysis provides insight into the quality of the sealing process, enabling operators to detect and immediately amend issues should they occur.

How does it work?

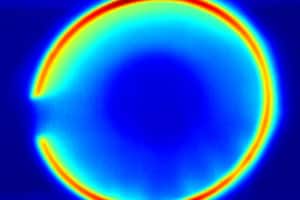

The Sealpro Total Automatic Conduction Sealing Machine combines SA’s proprietary thermal imaging technology for it’s heat sealing product portfolio. Utilising sophisticated analysis algorithms, the SealPro Total provides real time integrity monitoring of every single package or container on the packaging line – at the speed of the machine throughput.

Inspection is ‘hands off’, non-invasive and nondestructive. Nothing is projected at the product; the SealPro Total reads and analyses the inherent heat signature of the seal (which is amplified directly after the sealing process).

Benefits

- Offers a total 100% inspection —leaving the product completely sealed

- Applicable to containers of most common shapes and sizes in the food & beverage, cosmetics, nonwovens, pharmaceuticals and health & beauty industries

- Throughputs offered from 20 to 200 products per minute

- Inspection is live, ‘hands off’, non-invasive and non-destructive

- All welded to pharma sanitary standards using 316/304 stainless steel.

- Solutions are available in Sealing Only or with vacuum/gas facilities to extend the product shelf life.

- Easy-to-access ‘smart’ controls with multiple HMI’s

- The sealers are offered as either as Cut & Seal solution to seal and cut film coming from a reel or as a Seal Only solution from pre cut lids.

- Minimum foil waste between batches of 15-20mm, reducing waste

- Tolerance: margin 3-4mm, trim 10mm, reducing waste

- Sub 20 minutes changeover, reducing downtime!

- Sanitary design

- Sealing strength tuning and fine-tuning per each sealing head may be done separately via the HMI

- Explosion-Proof, Lid-Intrusion and ‘Breathing Foil’ upgrades available

- Offers a total inspection for 100% of products — leaving the machine completely sealed

- Industry 4.0-ready