Automatic Conveyors & Conveyors Feeding Systems

What is an Automatic Conveyor System?

An automatic conveyor system is a motor-driven system used to transport containers, products, or materials between stations on a packaging line without manual intervention. These systems employ belts, slats, or chains and may include sensors, guides, and control logic to maintain an efficient, synchronized flow of goods. They are essential for reducing manual labor, maintaining consistent product spacing, and accelerating production.

Automatic and Adjustable Conveying Systems

At Shemesh Automation, we offer a comprehensive range of automatic and adjustable conveying systems tailored to meet the needs of diverse products and container formats.

Our systems are designed for perfect integration within full production lines. One notable example is our dedicated conveyor for nonwoven rolls, developed to transfer them seamlessly from processing equipment to our liquid, solid or powder filling machines.

Benefits of an Automatic Conveyor System

- Reduces manual handling and labor costs

- Ensures consistent product spacing and alignment

- Boosts line speed and reduces bottlenecks

- Easily adaptable to different product shapes and packaging formats

- Modular and scalable for future line expansions

Types of Conveyor and Feeding Systems

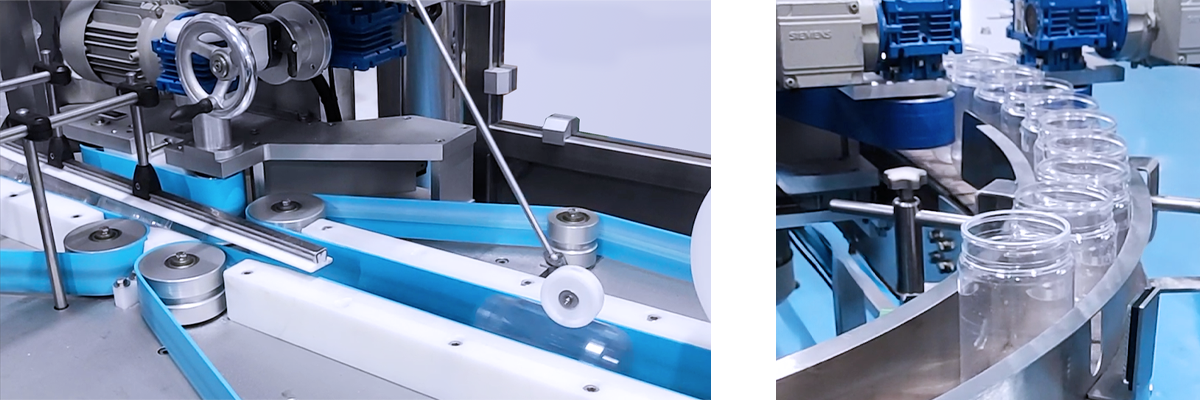

- Horizontal and vertical feeding conveyors

- Buffer, dividing, and merging conveyors

- Slat, pallet, chain, or belt conveyors

- Flow control and synchronization systems

- Custom-built conveyors by our engineering team

Featured Equipment Integrating Conveyor Technology

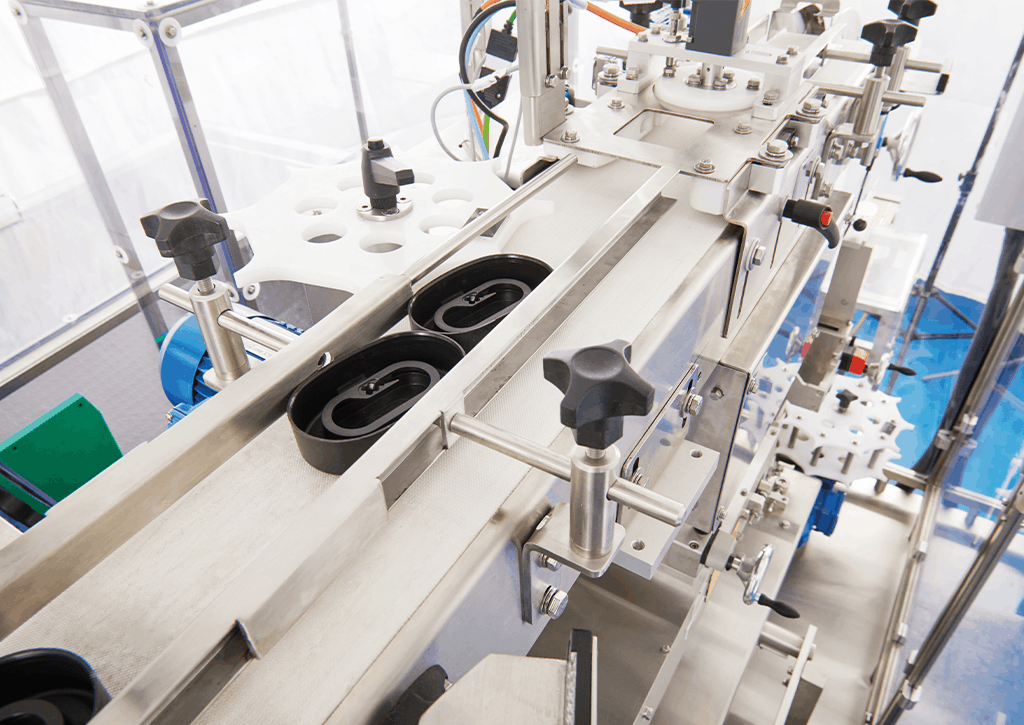

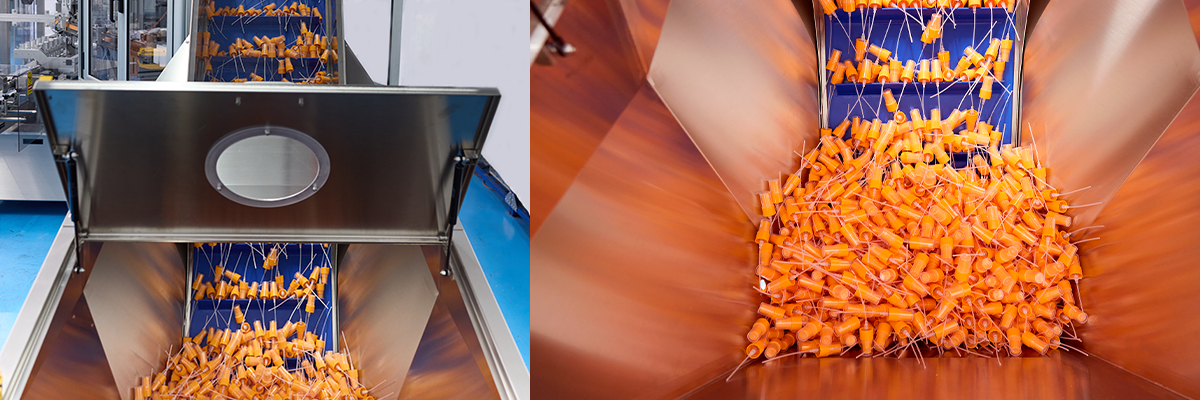

Automatic Caps Feeder – Hopper-Fed Vertical Caps Elevator

- The automatic cap feeder benefits from –

- Stainless Steel Hopper: Stores and dispenses caps steadily to the elevator. Multiple sizes available.

- Vertical Elevator Conveyor: Lifts and orients caps gently with low maintenance requirements.

- Horizontal Belt Conveyor: Maintains cap flow continuity before elevation.

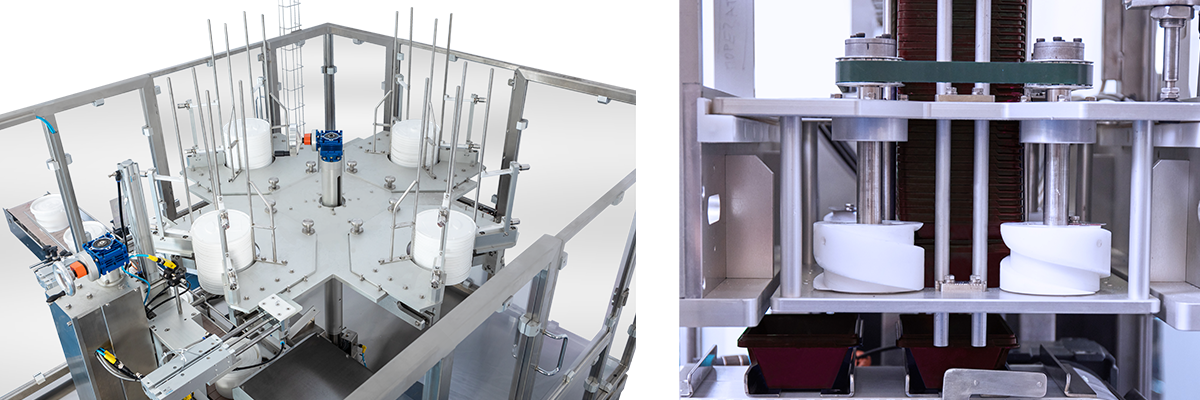

Automatic Unscrambler Machine

This unscrambler machine automatically arranges and orients bottles or containers, preparing them for downstream processes. Perfect for increasing line autonomy and reducing manual intervention at the start of the line.

Denester Machines

Our denesters are ideal for automatically separating and feeding containers, trays, or lids into the packaging line. Engineered for hygiene, precision, and easy changeovers.

Applications Across Industries

Shemesh’s automatic conveyor systems are used in a wide variety of sectors including food and beverage, cosmetics, chemicals, nonwovens, and household products. Whether transporting bottles, tubs, wipes canisters, or pouches, these systems improve operational efficiency, reduce downtime, and ensure optimal line performance.

Follow us on LinkedIn for more insights into our automated filling, capping, labelling, case packing, and palletizing solutions.