Thanks to Nonwovens Industry for publishing the following piece about our CITADEL-J in their Machinery & Equipment Review. You can read the full piece here.

Nonwovens Industry Machinery & Equipment Review: Shemesh Automation

Wipes manufacturers are increasingly transitioning from rigid packaging such as canisters and buckets towards flexible packaging in an effort to reduce carbon footprint and transportation costs. Also, while the initial Covid-related surge in demand for consumer wipes may have settled down post-pandemic, it’s clear that the market for jumbo wipes in flexible packs, commonly used in hospitals and gyms, is still growing apace.

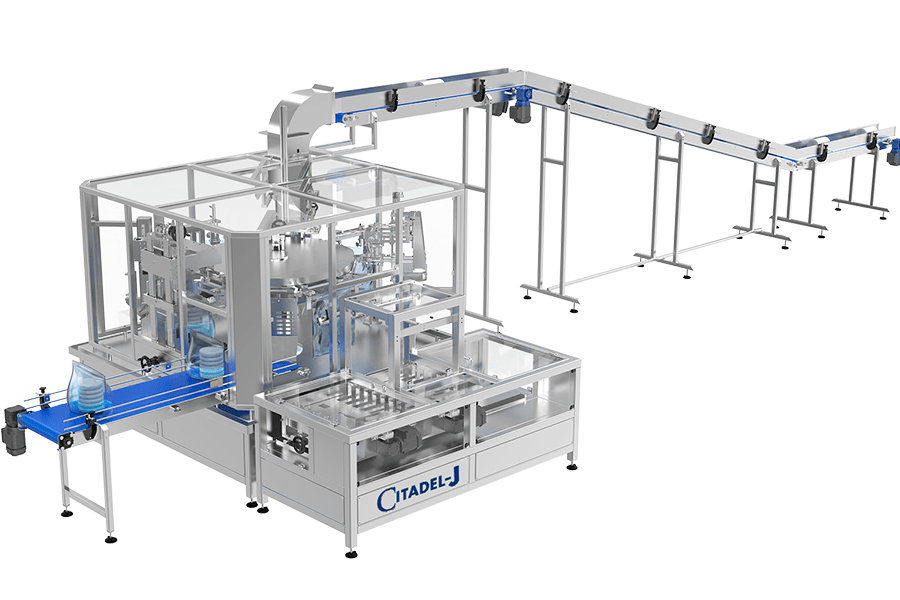

Responding to these emerging trends, Shemesh Automation has developed the perfect solution for manufacturers of wipes in flexible jumbo-sized bags who are looking to enhance their production with fast, space-saving automation: The CITADEL-J.

A stand-alone monobloc unit, the CITADEL-J automatically stuffs jumbo sized (typically in the 600 sheet-count to 1200 count range) nonwoven rolls into premade bags, accurately fills them with liquid (typically 3 to 5 liters) while providing constant support beneath the heavy bag, seals the bags and then ejects the finished product at speeds of 10-15 packs per minute (depending on product-specific variables).

- CITADEL-J is designed to connect seamlessly to existing slitter/rewinders, allowing manufacturers to benefit from complete A-Z hands-free operation.

- Main advantages:

- Throughput: 10-15 products per minute

- Adjustable rewinder-to-Citadel throughput technology

- Closed bags opening feature

- All welded to pharma sanitary standards using 316/304 stainless steel

- Designed for operational flexibility and ultra-low, tools-free sub 40 minutes format parts changeover downtime

- Industry 4.0 ready

- Advanced QC

- Enhanced, height-adjustable anti-overflow, proprietary designed filler nozzles. Portioning tolerance of 0.5% of filling volume – reducing waste

- Bag inflation: bags are inflated with the exact amount of air needed to facilitate speedy opening and rolls stuffing

- Two-stage filling, minimizing foaming and spillover while achieving a higher throughput

- Air evacuation

You can see the original article, a look at the latest technological developments from the major suppliers of nonwovens related machinery, which was published on 2/8/22 here