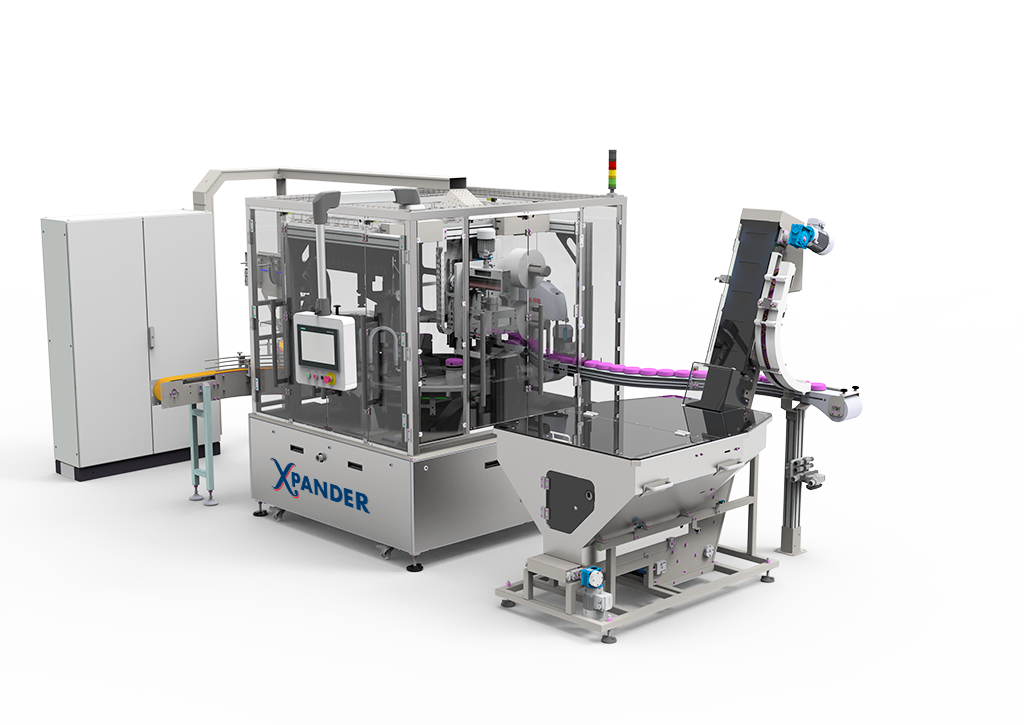

New generation of packaging automation with the Xpander Monobloc.

Innovation in Motion: A New Generation of Packaging Automation

In the nonwovens sector, some machines have made their mark. Designed to automate the packaging of canister wipes, certain integrated monobloc solutions have transformed entire production lines. Their agility, ability to simplify complex operations, and production reliability have made them essential.

But 2025 marks a new phase. Faced with rapidly evolving market demands and increasingly complex production environments, engineers embarked on a complete architectural overhaul. The goal was not to modernize, but to redefine.

This redesign was shaped by on-the-ground feedback. Operators, maintenance technicians, automation engineers, and designers collaborated to develop a smarter, more flexible machine – one that reflects real-world manufacturing needs.

Three major goals guided the effort: delivering stable output, simplifying user interaction, and improving integration. The result is a compact system that handles the full downstream process: roll stuffing, liquid dosing, conduction sealing, robotic capping with automatic cap feeding, and labeling – all synchronized with the upstream rewinder.

Responding to a Shifting Market

The wipes market is changing. Product diversification, new packaging formats, regulatory pressure, and cost containment all require systems that are adaptable and reliable. Flexibility is now essential: changing product, format, or cap type must be seamless, fast, and minimally disruptive.

A Reimagined Architecture

Servo-driven indexing replaced traditional systems, drastically reducing changeover time while improving accuracy. Format parts are color-coded for easier identification, setup, and training. Toolless format changeovers allow for smooth transitions between SKUs. The dosing system is modular, with tanks and pumps mounted on sliding rails, reducing footprint and simplifying maintenance. The conduction sealing station was reengineered for better film tension control and compatibility with synchronized printed films. Sensors across the machine deliver smart diagnostics: film break alerts, low product warnings, and net weight verification.

Robotics: Elevating Repeatability

At the capping station, robotics replace traditional mechanisms. A pick & place robot now performs cap application with high consistency and reduced vibration. Movements are recipe-driven: torque control, cap positioning, and height adjustment are automated. The system adapts to different cap types without manual intervention, aided by an advanced cap feeder and optional torque monitoring.

Operator-Centric Design

Despite its technical sophistication, this generation of equipment is designed for human ease. Transparent Lexan doors ensure visibility across stations. Access points are optimized for quick intervention and easy sanitation.

The HMI interface is designed for intuitive use: from recipe changes to diagnostics, operators benefit from clear, simplified navigation.

What Today’s Manufacturers Need

Manufacturers now require compact, complete, and intelligent systems. Floor space is limited, demand is unpredictable, and SKU changes are frequent. As such, fast changeovers, ergonomic layouts, and robust automation are essential to remain competitive.

Looking Ahead

The canister wipes market continues to evolve, driven by hygiene trends, innovations in substrate, and growing consumer expectations. To stay competitive, manufacturers need equipment that adapts easily while maintaining high output and quality.

Through increased integration, modularity, and robotics, the latest generation of automation meets the demands of modern nonwovens production environments – today and in the future.

For media and press releases, please download the PR here.

For editorial or sales enquiries please contact:

Nelly Desbiens

Marketing Director

Shemesh Automation

Email: Nelly.D@shemeshautomation.com

Website: shemeshautomation.com