How Monoblocs Are Redefining Canister Wipe Packaging in a Shifting Industry Landscape

Over the past decade, the monobloc packaging machine has redefined how canister wipes are produced and packaged. As consumer expectations, regulations, and sustainability goals evolve, manufacturers are adopting automation that delivers flexibility, precision, and speed. Compact and integrated, the monobloc packaging machine represents the new standard for efficiency in the canister wipes packaging industry.

A Decade of Transformation in Canister Wipes Packaging

The canister wipes packaging industry has evolved dramatically. Changing consumer behavior, new hygiene expectations, and tightening regulations have encouraged producers to invest in smarter automation. Across healthcare, homecare, and industrial markets, the demand for flexible, compact, and reliable systems continues to grow – and that’s where the monobloc packaging machine takes center stage.

By combining multiple functions into one unit, manufacturers can now meet smaller batch requirements, switch between packaging types, and maintain high output with reduced downtime.

The Rise of Monobloc Packaging Machines

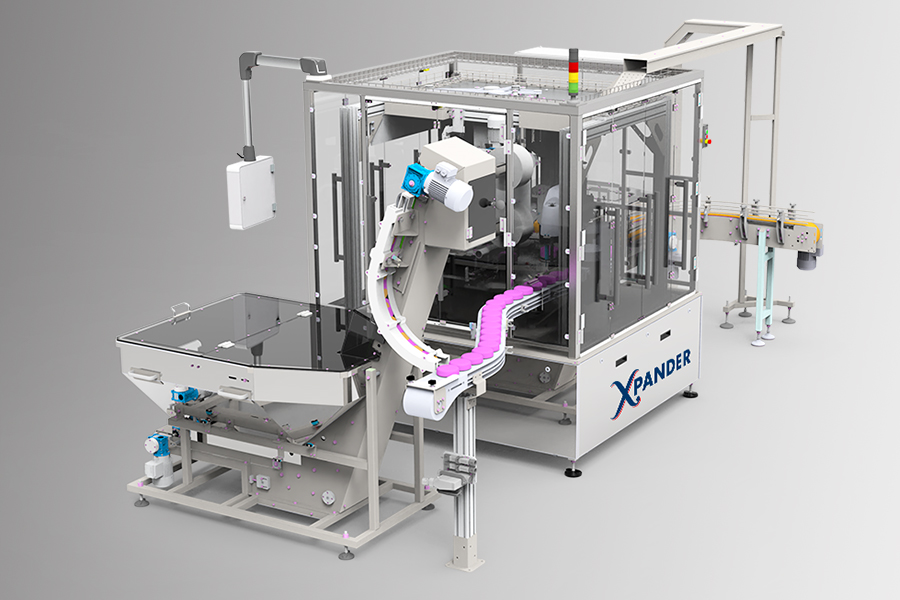

Modern monobloc packaging machines – like Shemesh Automation’s newly redeveloped Xpander Monobloc Round Wipes Packer – consolidate multiple packaging processes such as roll stuffing, liquid dosing, sealing, capping, and labeling into a single, compact system. A key feature of this new generation is the automatic cap feeder, which delivers caps directly to the capping station with precision and speed.

By automating the entire cap-handling process, manufacturers eliminate manual feeding and reduce line stoppages caused by misalignment or supply interruptions. This results in smoother, faster, and more consistent production.

In addition, the monobloc’s integrated cap feeding system minimizes floor space requirements and simplifies maintenance, making it an ideal choice for canister wipes producers seeking efficiency and reliability.

For canister wipe production, a monobloc packaging machine offers notable benefits: space optimization, easier maintenance, and consistent product quality – all while lowering operational costs.

Engineering the Next Generation of Monobloc Packaging Machines

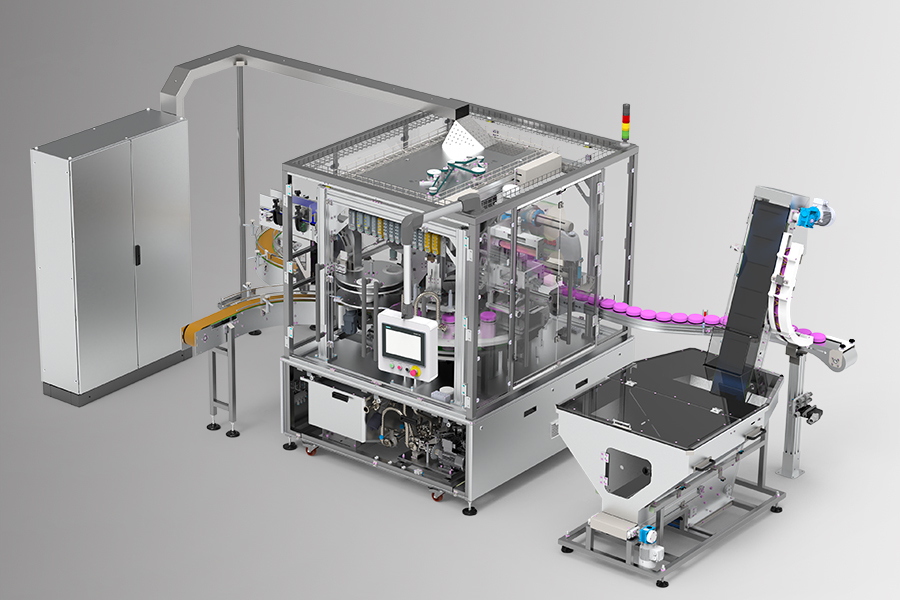

The latest generation of monobloc packaging machines has been redesigned from the ground up to address modern manufacturing challenges. Servo-driven indexing dramatically reduces format changeover times and automates adjustments like container height, cap torque, and cap type. Tool-free, color-coded format parts improve usability, while slide-out dosing tanks and pumps make cleaning faster and safer.

In sealing applications, new tension control systems and printed film synchronization enhance both performance and presentation. Integrated diagnostics monitor film breaks, detect low material levels, and verify net weight, allowing smoother, more transparent production.

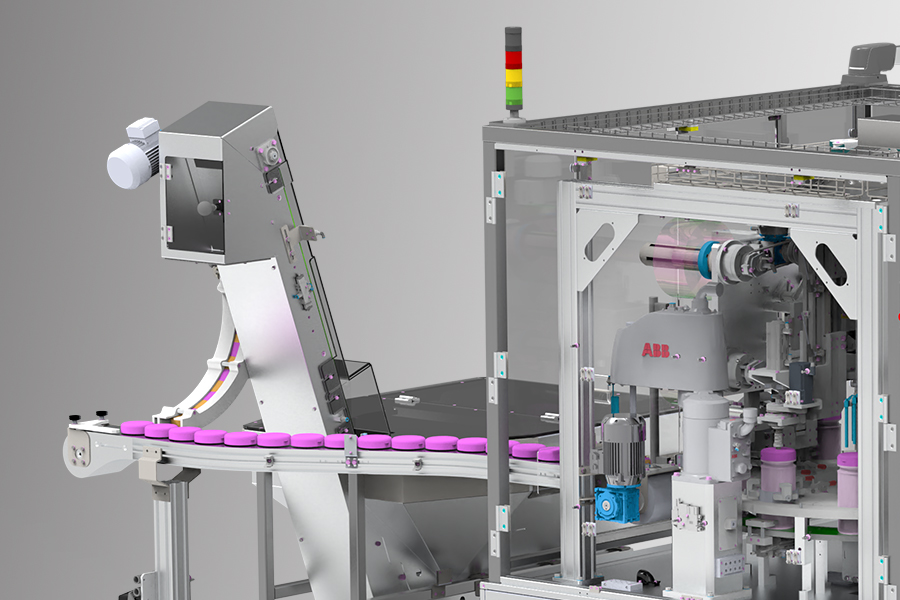

Robotics and Operator-Centric Design

Traditional capping systems are giving way to robotic pick & place modules, often powered by ABB delta robots. This ensures accurate, repeatable cap placement and minimizes mechanical wear. These innovations make the monobloc packaging machine ideal for high-speed environments with frequent product changeovers.

Equally important, operator-centric design has become a must. Transparent safety doors, ergonomic access points, and intuitive touchscreen HMIs reduce training time and enhance safety. Guided troubleshooting and digital reporting improve day-to-day usability and line reliability.

Smart Automation with Monobloc Packaging Machines

Today’s monobloc packaging machines are more than mechanical systems – they are digital, data-driven tools that align with Industry 4.0 standards. Equipped with smart sensors and connectivity options, they gather production data for real-time decision-making, predictive maintenance, and quality tracking.

Sustainability is also at the forefront. Sealing stations now accommodate recyclable films and bio-based laminates, while dosing systems can handle a wider range of viscosities for eco-friendly products. The compact footprint of a monobloc packaging machine helps manufacturers optimize space and minimize environmental impact.

The Future of Canister Wipe Packaging

As production floors face spatial constraints and faster market cycles, the monobloc packaging machine offers a clear competitive advantage. Its integration of precision, flexibility, and automation enables faster product launches, reduced downtime, and scalable efficiency – making it an essential tool for future-ready factories.

Ultimately, the evolution of the monobloc packaging machine illustrates how engineering and sustainability converge to meet modern production challenges. Compact, connected, and intelligent, it’s shaping the next era of canister wipes packaging.

Watch the Newly Designed Xpander Monobloc Round Wipes Packer FAT

Discover the newly designed Xpander Monobloc Round Wipes Packer by Shemesh Automation, filmed during its Factory Acceptance Test (FAT). See how this advanced monobloc packaging machine for canister wipes combines precision, compact design, and seamless integration into one intelligent system.

Get a Free Consultation

Looking to upgrade your canister wipes packaging line? Our experts can help you identify the ideal monobloc packaging machine for your production goals.

Follow Shemesh Automation on LinkedIn for more automation insights.