Shemesh Automation, global manufacturer of high-end packaging machinery, has relaunched its unique, sustainable range of monoblock all-in-one packaging solutions dedicated to the cosmetics, health and beauty sector. The packaging leader will be highlighting the range’s state of the art technologies on its stand at Cosmoprof Worldwide Bologna (10-13 March 2022).

The Monoblock series from Shemesh Automation encompasses all aspects of downstream packaging including feeding, filling, capping, double-capping, weighing, labelling, QC and discharging. The machines’ ultra-smart configurations are ideal for cosmetics and beauty applications including vials, roll-on deodorants, sprays and countless other products.

Art Malinowski, CMO at Shemesh Automation, explained: “Here at Shemesh Automation we’re dedicated to providing true single-source solutions for all stages of packaging cosmetics and other health and beauty products. Not only do we offer unrivalled process flexibility, we also deliver significant sustainability benefits and reductions in operational costs. That’s an unbeatable combination for all of our current and future cosmetics and beauty customers.”

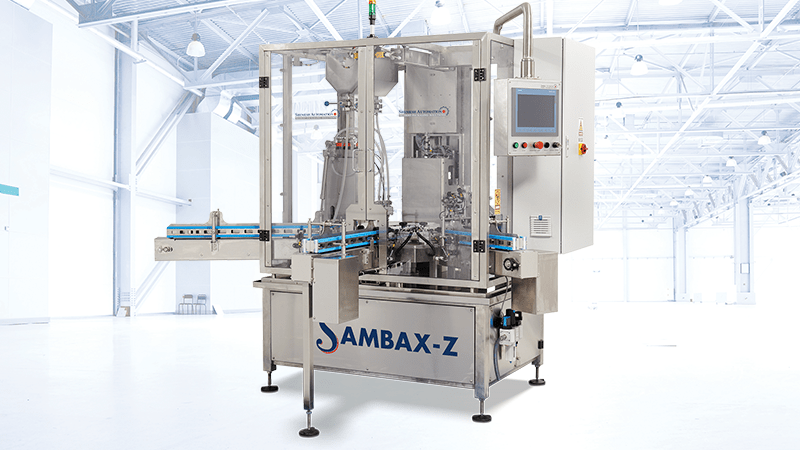

Sambax has proven technologies for cosmetics packaging

Shemesh’s decades of experience developing solutions for cosmetics has culminated in the Sambax-Z, a single small (1520mm L x 1050mm W) Monoblock packaging machine tailored to the sector. This baby brother to the Sambax, both of which offer a unique and truly universal monoblock design, is designed especially for small and extra small containers and vials ranging from 350ml right down to 5ml.

Fabricated from stainless steel 316L to Western European pharma grade machine build standard, the Sambax-Z is the go-to for fully automatic feed, fill, pick & place cap and overcap with quality control. Operating with liquids up to 95ºC (203ºF), Sambax-Z offers double servo filling technology in both the pistons and the diving nozzles for production consistency – and a staggering +/-0.25% of liquid volume accuracy.

Throughput range is from 20ppm up to 100ppm and there are up to 20 programmed product recipes to choose from. The Sambax-Z is Industry 4.0 ready with an integrated Secoma Site Manager 1139 modem. That’s in addition to a built-in HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback.

Built in CIP (clean in place) with enhanced cleaning from built-in spray balls brings labour and time savings. Together with a filling auto flushing mode, the Sambax-Z brings highly cost effective, time efficient line maintenance, cleaning and changeover.

Hands-free flexible pouch filling

Shemesh Automation has also relaunched the Encore Monoblock pouch filling machine. With operating speeds of up to 60ppm, Encore is a robust, fully automatic, servo driven vertical index machine, specifically designed as a single block for the downstream packaging of liquid, solids, tablets or powder in flexible bags.

The unique Encore Monoblock includes filling, portioning and sealing as a hands-free turnkey unit for both regular and jumbo doypacks ranging from 140mm to 550mm in width. It has a filling range of 50ml to 5L for solids, granules or powders – with or without liquid products – and, like its equally state of the art cousin Sambax, is precision-designed and Industry 4.0 ready with SMART support HMI.

Encore is designed as a space sensitive machine to pharma sanitary standards using 316L stainless steel and USDA/FDA approved materials. Its operational flexibility and an ultra low parts changeover downtime, tools free and sub-30 minutes, is assured. Encore also reduces waste via portioning tolerance of 0.5% of filling volume and anti-overflow filler nozzles. Bags are inflated with the exact amount of air needed to facilitate speedy opening and filling, and there is two-stage filling for liquids, minimising foaming and spillover whilst achieving a higher throughput.

Building sustainably

Shemesh Automation CMO Art Malinowski concluded: “As a major supplier of packaging machinery across the world, we bear a heavy responsibility to customers to develop machines that are designed and built with sustainability in mind. This helps our customers and industry as a whole to act on their commitments to the circular packaging economy.

“Yes, of course we can meet demand for large production facilities but the trend for smaller, more specialised production lines is gaining traction. Small footprints and innovative process efficiencies reduce use of energy and water, the latter also reducing waste. That’s where our focus is, and that’s where our Monoblock range brings unrivalled advances in cosmetics packaging. We’re looking forward to showcasing these benefits to old friends and new at Cosmoprof in March.”

Cosmopack, a division of Cosmoprof, is the leading international event fully dedicated to the entire supply chain of the cosmetics industry: ingredients and raw materials, contract and private label manufacturing, packaging, applicators, machinery, automation and full-service solutions. Visit Shemesh Automation Hall 20 Stand A35, 10-13 March, Bologna.

Article featured on Innovations in Food Technology