Gallery

The World’s First Empirically Proven Round Wipes Canister Loader

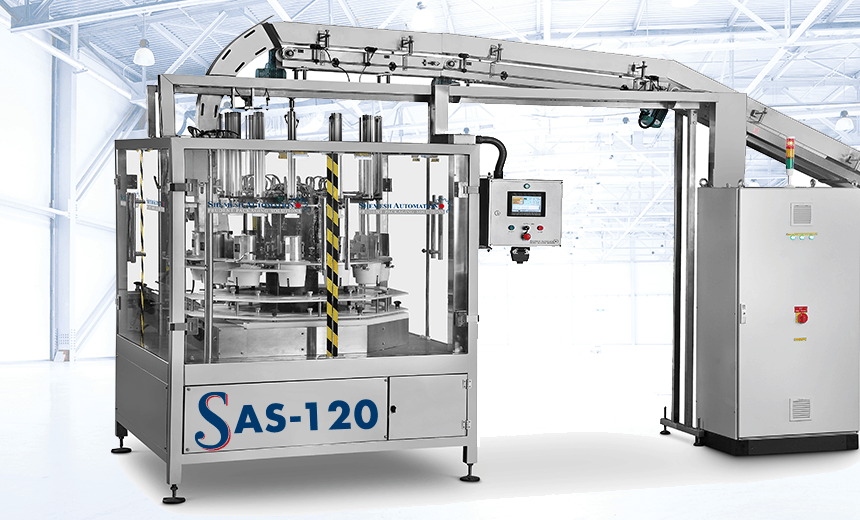

A truly revolutionary high-speed vertical round wipes canister loader, the SAS120 is the first empirically-proven wipes loading machine of its kind.

It offers unprecedented speeds and accuracy levels, reinventing operations and efficiency.

Officially rolled out in 2013, the SAS120 is the first vertical nonwovens rolls stuffer to hit the market and has been used to great benefit, by some of the world’s largest manufacturers of round wipes.

Available both as a stand alone unit, or as part of our complete turn-key wipes packaging lines, the SAS120 is engineered so that the diameter of each wipes role may be larger than the canister opening by up-to 3mm -a big plus!

Also, because of its economical, vertical design, the SAS120 takes less than one third the space required for average horizontal stuffers – saving you much needed factory floor-space!

The SAS120 is also compatible with all recommended round wipes converters/rewinders, giving you a complete ‘hands free’ start to your line.

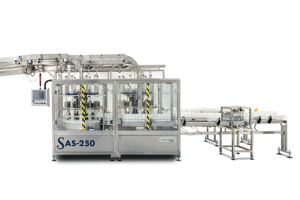

The SAS Stuffer is now also available as a super-fast 250ppm model – the fastest machine of it’s kind available anywhere in the world today! Contact us for more information.

Also, don’t forget to visit our dedicated wet wipes site for our complete range of wet wipe packaging machinery: www.sawetwipes.com

Benefits

- Throughput models offered: 60, 120 or 250 products per min

- Methodology. Vertical chute and a main servo-driven rotary turret

- Newly developed capping mechanism for round cans lids

- Designed for operational flexibility – ultra low, tools free changeover downtime

- Space. Takes less than one third the space required for the average horizontal stuffers

- Newly developed design for vertical wipes can loading

- Synergy. Compatible with all of our downstream portfolio and offered converting machines

- Setups, operation & maintenance. Sub 30 minutes changeover downtime. Easy to operate & maintain

- Tolerance: rolls may be wider by up to 3mm than the canister opening, a BIG plus!!

- Sub 30 minutes changeover, reducing downtime!

- Supporting both round and oval canisters

- Smart controls. Seamless line integration. Adjustable throughput technology

- Developed over 3 years with over 20 machines installed since officially rolled out in 2013