Gallery

The SA-CF120 is an Automatic Container Unscrambler engineered for high-speed feeding and orientation of bottles and canisters at the start of the packaging line. It supports multiple container formats and delivers up to 120 units per minute with stable and repeatable orientation accuracy.

Fully Synchronized Unscrambling

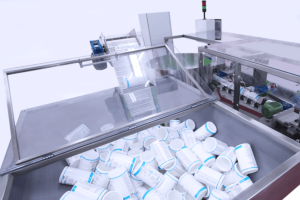

Operators load empty containers into the stainless-steel hopper, which includes level transmitters for “half full” and “empty” status. The elevator conveyor then transfers containers to a centrifugal feeding plate, where the initial orientation process takes place. Afterwards, containers move into a side conveyor for final orientation.

The upper belt section applies a controlled pressing or guiding force. As a result, every container leaves the machine standing vertically and enters the main conveyor in the correct position for downstream filling, capping or labelling. This design eliminates manual intervention, improves operational efficiency and reduces handling errors in continuous production.

Benefits

- Fully automatic operation with minimal operator input

- Stainless steel 304 frame, conveyors and machine parts

- RHS 40 stainless-steel base with reinforced cube-shape construction

- CE compliant with sanitary welds

- SIEMENS PLC and touchscreen HMI for recipe control and diagnostics

- Omron or Sick sensors for stable and reliable detection

- Festo or SMC pneumatic components for long service life

Industry 4.0 Ready

All Shemesh Automation start-of-line systems are Industry 4.0 ready. The SA-CF120 Automatic Container Unscrambler includes a SECOMA Site Manager 1139 modem integrated into the HMI for SMART remote support, live performance statistics, diagnostic data and manufacturer feedback.

This capability provides advanced monitoring and helps keep the machine aligned with modern production and maintenance standards.

Applicable Sectors

- Food & Beverages

- Cosmetics, Health & Beauty

- Pharma and Biotech

- Chemicals

- Nonwovens and household products

How the SA-CF120 Works

The SA-CF120 is the flagship front-of-line solution within Shemesh Automation’s container handling range. This Automatic Container Unscrambler handles different bottle shapes and sizes without requiring additional changeover parts. Furthermore, its robust mechanical structure and intuitive HMI support consistent performance during long production runs.

First, empty containers enter the hopper. Next, the elevator system delivers them to the centrifugal disc for initial orientation. Subsequently, containers move to the side conveyor for final orientation. Finally, they exit the machine in an upright position and continue downstream in perfect alignment for accurate filling.

Explore More Unscrambler Technologies

To explore other container orientation systems in the Shemesh Automation portfolio, visit the

Automatic Unscrambler Machine overview page.

FAQ – SA-CF120 Automatic Container Unscrambler

Does the SA-CF120 handle multiple container formats?

Yes. It can orient round, oval, square and irregularly shaped bottles or canisters.

Can the machine integrate into an existing production line?

Yes. The SA-CF120 integrates seamlessly with any filling machine or complete packaging line.

What speeds can the SA-CF120 achieve?

Depending on container type and size, the machine can reach very high throughputs. Contact us for exact performance specifications.

Speak to Our Experts

Contact our team to evaluate Automatic Container Unscrambler compatibility with your container formats, speeds and line layout:

Speak to our experts.

Follow Us

Stay updated with automation insights, upgrades and installations.

Shemesh Automation on LinkedIn.