Gallery

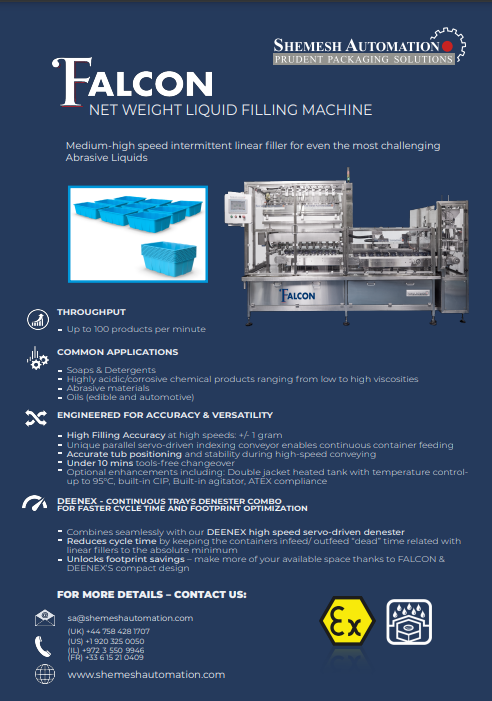

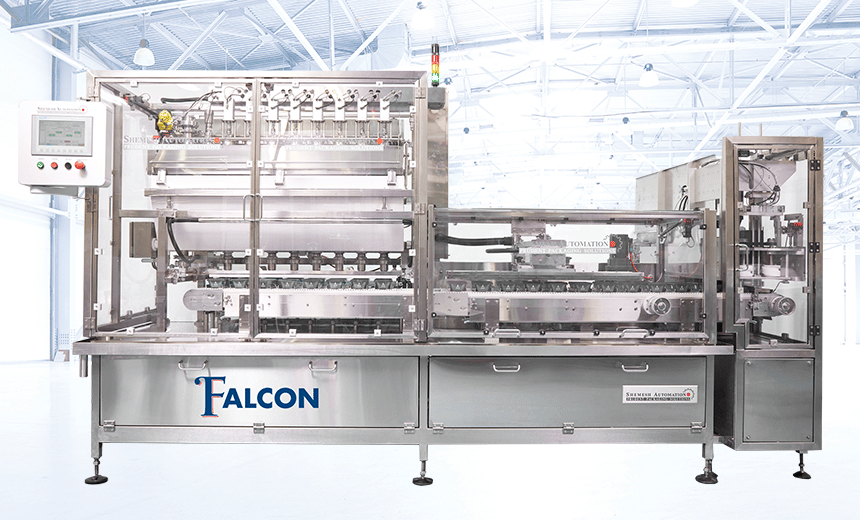

The “Falcon” Net weight liquid filler is a state-of-the-art, medium- high speed intermittent linear filler design, engineered to accommodate the most challenging and abrasive liquids, with high accuracy filling capabilities for a variety of products from low to high viscosity.

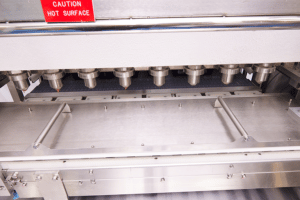

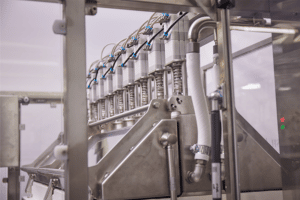

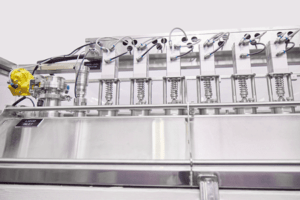

The liquid flows from the tank to the tubs/containers through gravity, while each filling station is equipped with a load cell for maximum accuracy with the most inconsistent liquid.

Common Applications

- Soaps & Detergents

- Highly acidic/corrosive chemical products ranging low to high viscosities

- Abrasive materials

- Oils (edible and automotive)

Infeed combo for faster cycle time and footprint optimisation

The Falcon combines seamlessly with our DEENEX high speed servo-driven denester to reduce cycle time by keeping the containers infeed/ outfeed “dead” time related with linear fillers to the absolute minimum. This powerful combination allows for increased automation of your production line and allows you to unlock the full throughput potential of your space, making the absolute most out of its footprint.

Benefits

- High Filling Accuracy at high speeds: +/- 1 gram (tested with water)

- Throughput: Up to 100ppm

- Nozzles are engineered to achieve maximum flow and are equipped with a pneumatically actuated seal.

- Accurate tub positioning and stability during high speed conveying

- Under 10 mins tools-free changeover

- Full recipe control via HMI

- INDUSTRY 4.0 READY: SECOMA SiteManager 1139 modem, integrated into the machines’ HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback.

- “No bottle no fill” function

- Optional enhancements including: Double jacket heated tank with temperature control- up to 95°C, built-in CIP, Built-in agitator, ATEX compliance