Gallery

Automatic Tray Denester for Food Packaging Lines

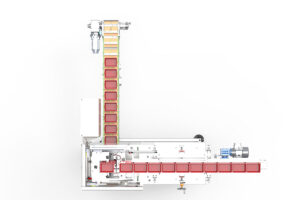

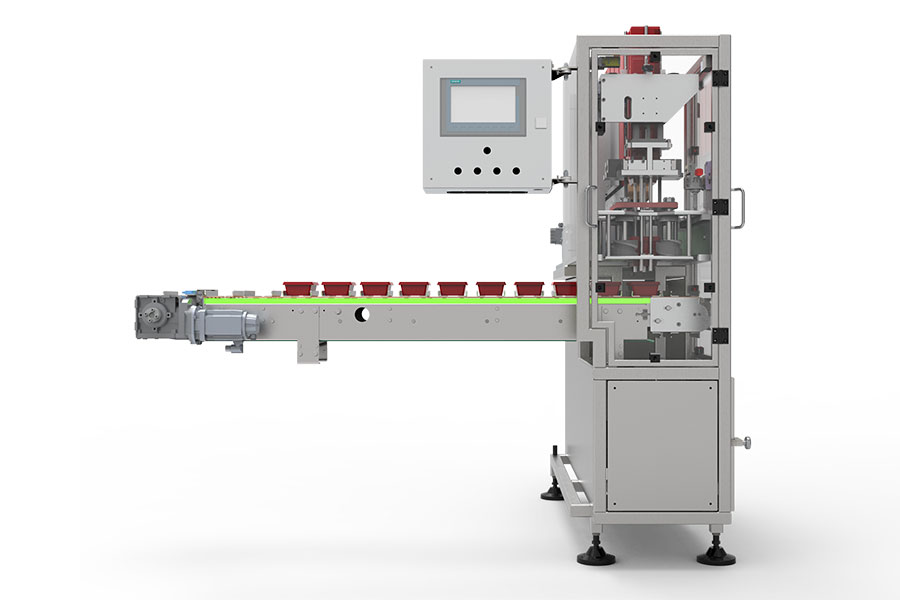

The Shemesh Automation automatic tray denester continuously feeds your packaging line by separating stacked trays one by one and placing them precisely onto the conveyor. As a result, manual handling drops significantly and production throughput stays stable throughout the shift.

Designed for thermoformed or injection-moulded food trays, the system integrates smoothly upstream of a filling machine, tray sealing unit or labelling station. Moreover, it is ideal for ready meals, fresh food, snacks and frozen products, making it a versatile choice for many food producers.

How the Tray Denester Works

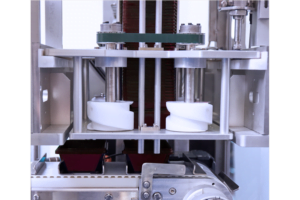

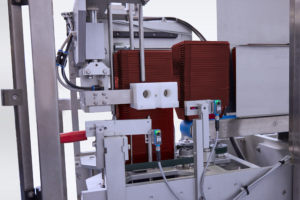

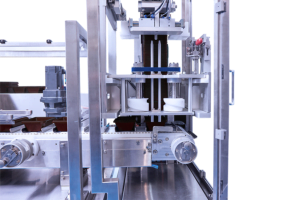

First, operators load stacks of trays into a high-capacity vertical magazine. A servo-driven mechanism then separates trays from the bottom of the stack and transfers them onto the infeed conveyor. In addition, full synchronisation with the rest of the packaging line keeps tray positioning consistent for filling, sealing or weighing operations.

- Automatic denesting of stacked trays.

- Magazine can be refilled during operation without stopping production.

- Smooth and controlled tray transfer that preserves tray integrity.

- Fully synchronised with the conveyor and downstream stations.

Key Advantages of the Tray Denester

- Reduced labour required for manual tray loading.

- High and consistent throughput suitable for modern packaging lines.

- Fewer jams and unplanned stops thanks to accurate tray placement.

- Wide compatibility with various tray sizes and depths.

- Stainless steel construction suited for demanding food-production environments.

- User-friendly HMI with recipe storage for quick format changes.

Main Technical Features

- Indicative speed: up to XX trays per minute (depending on tray design and product).

- Compatible with thermoformed or injection-moulded trays, single or multi-compartment.

- High-capacity tray magazine with front or side loading.

- Servo-controlled denesting and transfer mechanisms.

- Fast, tool-less adjustments for format changeovers.

Typical Applications

The tray denester integrates easily into lines for the following applications:

- Ready meals and prepared dishes.

- Meat, poultry, fish and other fresh food products.

- Snacks, deli products, salads and frozen foods.

- Multi-compartment trays for cheese, desserts and confectionery.

Integration into Existing Lines

You can install the tray denester on a new line or use it to replace manual loading stations. Furthermore, the Shemesh engineering team reviews your throughput requirements, tray formats and plant layout to provide a tailored integration plan that may include conveyors, guides, change parts and inspection devices.

Additionally, for sites handling several packaging types, the tray denester works seamlessly with our automatic denesters to create a fully automated front-of-line solution.

FAQ – Frequently Asked Questions

Which tray types are compatible?

The machine accepts most standard market trays, whether thermoformed or injection-moulded, single or multi-compartment. Dedicated format parts enable quick adaptation to different tray geometries.

Does the denester match the speed of my tray sealer?

Yes. The denester synchronises automatically with the downstream sealer or filler and follows line speed while keeping a continuous and stable tray flow.

How are format changes performed?

Operators adjust most settings directly through the HMI, and they can swap format parts quickly when needed. In addition, recipe storage enables rapid setups and helps minimise downtime.

Speak to Our Experts

Contact our team to evaluate tray denester compatibility with your tray formats, required speeds and line layout: Speak to our experts.

Follow Us

Stay updated with automation insights, engineering updates and new machine installations. Follow Shemesh Automation on LinkedIn.