Gallery

Air Rinsing Machine for Bottles and Jars – EXANE Automatic Inverting Air Rinser

EXANE Air Rinsing Machine – Automatic Inverting Air Rinser for Rigid Containers

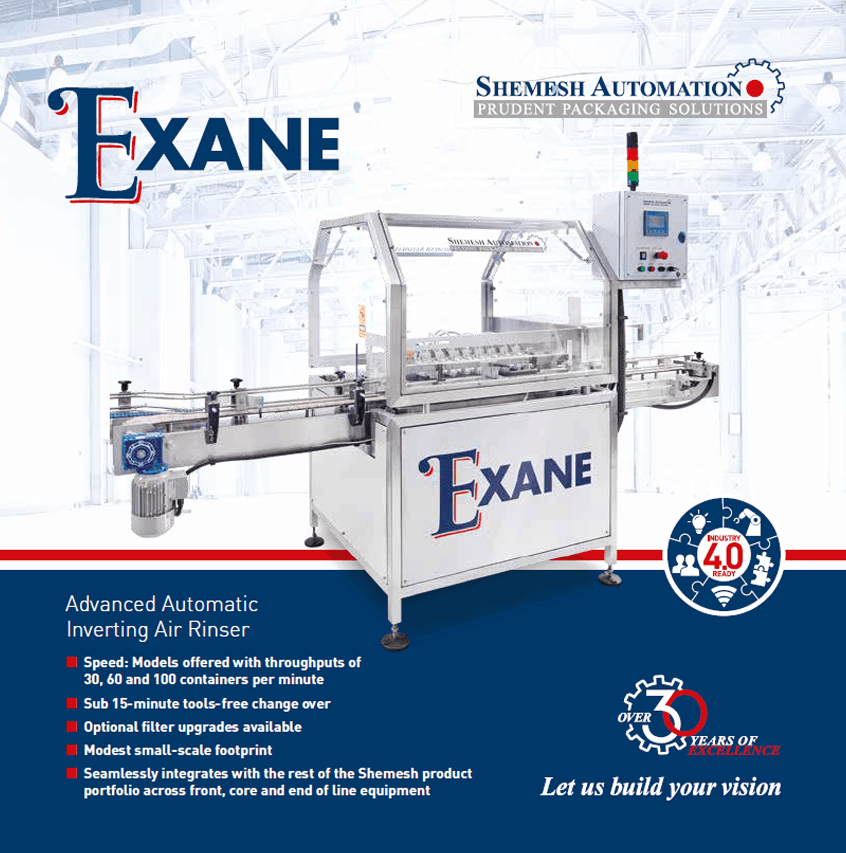

The EXANE Air Rinsing Machine is a servo-controlled, high-precision system engineered to deliver reliable, hygienic container cleaning for the Food & Beverage, Cosmetics, and Pharmaceutical sectors. Designed for bottles, jars, and rigid containers made of plastic, glass, or metal, EXANE ensures each container is thoroughly cleaned before filling and capping.

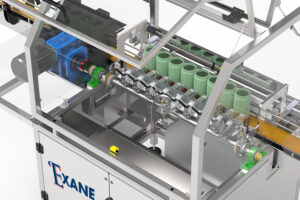

Using an advanced inverting mechanism with precision grippers, the EXANE flips each container upside down and injects a controlled, filtered burst of compressed air inside. This process effectively removes dust, particulates, and other contaminants accumulated during storage, conveying, or handling.

As a high-speed air rinsing machine, EXANE combines robust mechanical design with hygienic construction to maintain consistent container cleanliness even in demanding production environments.

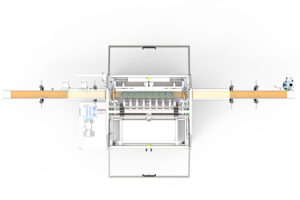

Built with a robust 304-grade stainless-steel frame, EXANE features an intuitive HMI, full safety guarding, upward-opening doors for easy access, and compatibility with both linear and rotary filling lines. Its compact footprint allows seamless integration within new or existing packaging lines.

Technical Advantages

- Fully automatic inverting air rinsing for consistent container cleanliness

- Available capacities: 30, 60, or 100 containers per minute

- Fast tool-free changeover – typically under 15 minutes

- Full hygienic construction in 304 stainless steel

- Supports round, oval, square, and irregularly shaped containers

- Compatible with glass, plastic (PET/HDPE), aluminum, and metal containers

- Equipped with high-efficiency air filtration; optional 3-stage filtration available

- Explosion-proof (ATEX) and corrosion-resistant versions available

- Optional vacuum-assisted air rinsing for ultra-clean applications

- Designed for quick cleaning, format adjustments, and low-maintenance operation

- Fully integrable with Shemesh’s complete filling, capping, sealing, and case packing lines

Additional Benefits

- Safety & compliance: Explosion-proof and anti-corrosion designs available for demanding industrial environments

- Enhanced cleaning: Optional vacuum-assisted air extraction for superior particulate removal

- Reduced downtime: Smart engineering and ergonomic access points streamline maintenance and changeovers

For complete technical specifications, download the full EXANE brochure.

FAQ – EXANE Automatic Air Rinser

Does the EXANE rinser handle multiple bottle formats?

Yes, EXANE can process various bottle and container formats depending on your production line requirements.

What type of cleaning does EXANE perform?

The machine uses an air-inversion blowing system that effectively removes internal particles before filling.

Can EXANE be integrated into an existing production line?

Yes, the EXANE air rinser integrates seamlessly with any filling machine, capping unit or monoblock system.

What speeds can EXANE achieve?

Depending on the container type and configuration, EXANE can reach very high throughputs. Contact us for exact performance specifications.

Discover how the EXANE Air Rinsing Machine can elevate hygiene, speed, and reliability across your packaging line. Contact our team for a tailored consultation or request a budgetary quote today.

Follow us on LinkedIn for updates, engineering insights, and case studies.