Headquartered in Austin, Texas, Yellowbird Foods has experienced rapid growth since they debuted at a local farmers’ market in 2013.Yellowbird’s rise to the top came as they built a reputation for quality, from their meticulous automatic liquid filling machine production methods to every flavour-packed millilitre of the final product.

Yellowbird® are famous for packing their sauces with fresh fruits and vegetables to create sauces that are smoother but also more viscose than standard sauces. They also pride themselves on consistency of flavour, meaning every bottle of sauce packs a punch with their signature bold and spicy flavours.

Now a top 10 sauce supplier on Amazon, the dramatic increase in demand for their fresh tasting spicy condiments soon necessitated an increase in production. But with such meticulous standards in product quality, sourcing equipment capable of achieving production consistency at high throughput would be no easy task. Thankfully, Yellowbird® found Shemesh Automation.

With over 30 years’ experience delivering high-end turnkey packaging lines to manufacturers all over the world, Shemesh was able to deliver a sauce filling, capping and labelling solution that offered Yellowbird® an enhanced throughput of 100ppm, whilst ensuring the highest standards in product consistency, hygiene and efficiency.

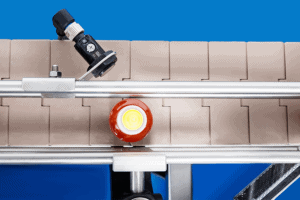

The featured line included Shemesh’s flagship dynamic duo – STRATUM II and THORO II. STRATUM II, an advanced in-line double servo driven automatic liquid filling machine and THORO II, a robust servo-driven cam designed double station capper, specifically designed to provide super-accurate, leak free capping were ideally suited to Yellowbird’s requirements.

The capacity and speed of each unit afforded the client the ability to seamlessly fulfil each product range with minimal downtime between runs, thus reducing costly capital outlays, space and utility consumption associated with multi production lines. STRATUM’s empirical ability to negotiate a wide range of viscosities meant the Yellowbird® sauces retained their enticingly smooth mouth feel and famous fresh punchy flavour.

The line also included Shemesh’s flagship labelling machine – the LWA Series – which delivered ultra-accurate wraparound labelling to apply the finishing touch to Yellowbird®s famous bottles.

|

|

|

See the 100ppm line in action here.

Kevin Uplinger, COO of Yellowbird® commented: “Our significant growth in recent years made it essential for us to increase our production capabilities in order to address the demand for our sauces. Selecting the manufacturer for such a line is one of the most important decisions you can make. Of course, enhanced production capacity is important but even more so is the integrity of our product. Ensuring that our selected manufacturer understood the importance of maintaining the quality of our sauces throughout the packaging process was absolutely paramount.

The experience Shemesh has demonstrated during their 30 years of serving premium food brands was therefore highly significant in our decision to work with them on the project. I’m delighted to say that we made the right choice as Shemesh has delivered on all fronts – from the efficiency of the process to the quality of the final product, we couldn’t be happier. I wouldn’t hesitate to recommend Shemesh to any other manufacturer who wants to increase their production capacity without compromising on product quality.”

Bob Green, Sales Director – North America, Shemesh USA, Inc. commented: “Yellowbird® and Shemesh actually enjoy many similarities as businesses – from experiencing rapid growth in a relatively short space of time, to our mutual determination to never compromise on quality. I believe these shared experiences and values, together with our depth of experience in providing such high-quality machinery to some of the world’s biggest names, has helped to make this partnership the success it has been. I’m incredibly proud to see the impact Shemesh machines are already having at Yellowbird® – helping them to meet the demand for their amazing product whilst also reducing waste, utility consumption, and changeover time within an ergonomic production centre footprint.

With the new Shemesh USA, Inc. sales, service and parts distribution facility opening in Green Bay, Wisconsin during the second quarter this year, Yellowbird Foods, and all of our North American customers, will benefit from expedited, local technical service and parts in the future. Our goal is simply, top quality customer service without compromise.”