Gallery

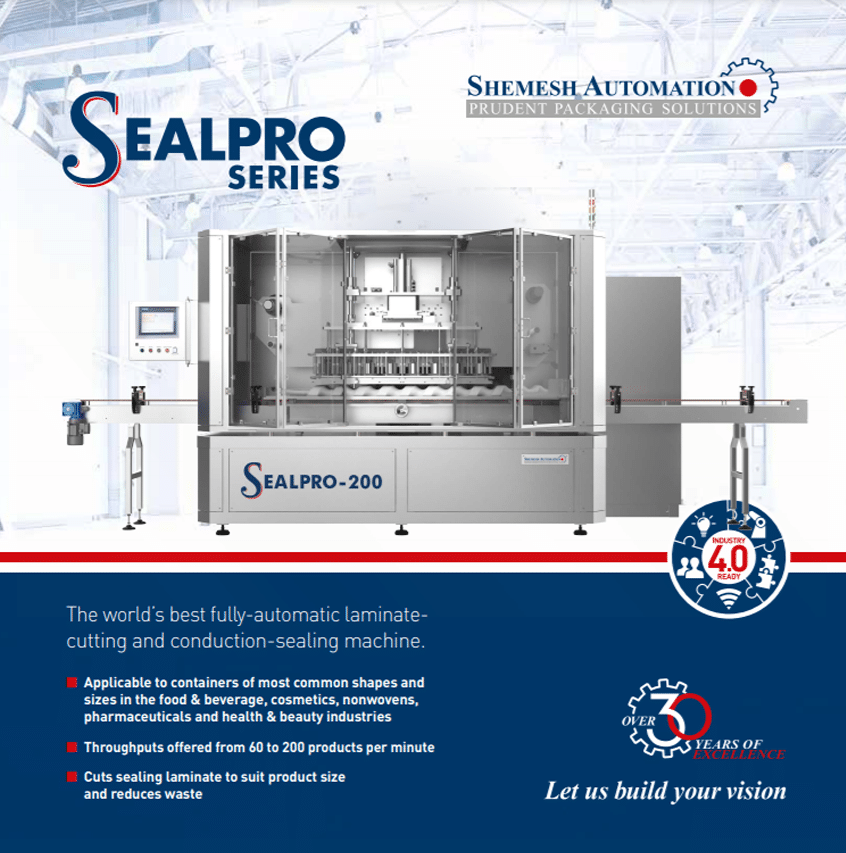

Shemesh’s all-new SealPro 200 Automatic Continuous Conduction Sealing Machine means manufacturers no longer have to choose between speed and waste reduction, efficiency and sustainability, premium machinery and extra floor space – they can now have it all!

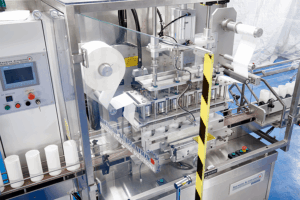

The SealPro 200 Conduction Sealing Machine is a linear-designed machine that automatically cuts the foil laminates according to the container size, stretches it and conduction seals the container at high speed. The SealPro200 has ten (10) welding heads installed within the one robust sealing block, which allows it to achieve 200ppm speeds.

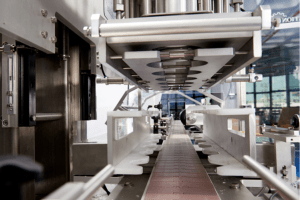

The SealPro200 features a double servo driven screw feeder to introduce the containers, accurately position them under the sealing zone and discharge them out of the machine. As well as being accurate and consistent, the SealPro200 boasts unique design aimed at eliminating container slippage which may otherwise happen due to possibly wet conveyors, thereby reducing waste.

The SealPro200 Conduction Sealing Machine is robust, accurate, consistent and works with most PE-based laminates existing in the industry.

How the SealPro 200 Conduction Sealing Machine works

Containers arrive to the SealPro200 conveyor where each product goes through a double servo driven accurate screw feeder for an accurate, high-speed feeding, registration and positioning of each canister under its designated conduction seal & cut unit.

Once detecting ten (10) containers under the sealing block, a sensor commands the sealing block to descend, press, stretch, cut the laminate and weld it to the canisters ring. Once a sealing cycle is complete, canisters are directed by the double servo driven screw feeder towards the chosen capping machine.

General Specification:

- Throughput: up to 200ppm.

- SealPro200 main frames and construction base made of stainless steel SST304.

- Stainless steel SST304 slat chain conveyor. Dimensions width: 130mm, length 5m.

- Servo driven double SCREW FEEDER for accurate, high-speed feeding registration and positioning of canisters arriving to their conduction seal & cut units.

- Designed for sealing up to ten (10) canisters per cycle.

- Controls platform: Siemens or Allen Bradley

- Gears and motors: SEW Germany

- Pneumatics: Festo Germany

- Sensors: Banners

- Machine is Industry 4.0 ready.

- Explosion proof / Corrosion proof upgrades available

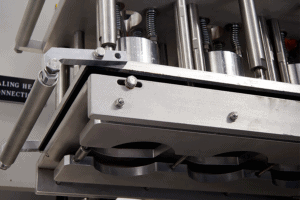

- Each sealing head “sits” on springs to allow for slight cans height differentials (as those molds are never perfect!) and is individually controlled from the HMI for several critical parameters.

The Sealing block:

- Each sealing block is designed for one size of container +/- 5 mm.

- Sealing block height digitally adjusted (up/down).

- Ten (10) heating zones, each controlled by an individual temperature controller.

- Cutting knives for film roll cutting according to the product required diameter and shape.

- Entire machine changeover (sealing block and screw feeder) is fast, user-friendly and tools-free.

- Automatic Foil Tension Control.

We strongly recommend that for these throughputs the SEALPRO 200 Conduction Sealing Machine should be used together with its Shemesh designed Continuous Jumbo Rolls Magazine.

If you don’t need such a high throughput Shemesh’s regular SEALPRO could be a better fit for you. Please see more info here.

Please contact our team of expert sales engineers who can advise you further.