Gallery

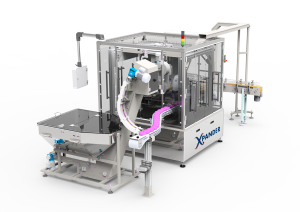

Xpander Monoblock Canister Wipes Machine

The Xpander Monoblock Canister Wipes Machine is a fully integrated solution engineered to automate every step of the downstream packaging process for round wet wipes in canisters. Built for reliability, flexibility, and precision, it streamlines production from roll stuffing to final labeling.

All-in-One Xpander Monoblock Automation

Designed to consolidate operations into a single compact footprint, the Xpander Monoblock Canister Wipes Machine handles:

- Automatic roll stuffing

- Liquid dosing (up to 450cc)

- Conduction sealing with film break sensors

- Robotic pick & place capping with torque control

- Automatic cap feeder for uninterrupted cap supply

- Front/back, wraparound, and other label configurations depending on canister format

- Built-in smart quality control (sealing, torque, weight check)

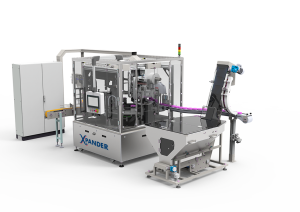

Production Efficiency & Flexibility

With a throughput of 30 to 35 canisters per minute, the Xpander Monoblock aligns precisely with upstream rewinders. Its servo-driven architecture supports fast, toolless changeovers in under 40 minutes, making it ideal for varied SKUs.

- Color-coded format parts simplify changeover and training

- Slide-out dosing tanks and pumps reduce machine footprint

- Height-adjustable filling nozzles eliminate spillage

- Compatible with round, oval, conic & rectangular containers

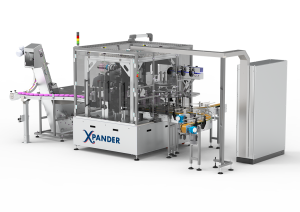

Operator-Centric Xpander Monoblock Design

This canister wipes packaging machine includes multiple user-friendly features for ergonomic access and intuitive handling:

- Large transparent Lexan safety doors

- Multiple HMI interfaces for real-time diagnostics and control

- Automated height adjustments linked to product recipes

- Direct and easy integration with rewinder

Smart Manufacturing, Industry 4.0 Ready

The Xpander Monoblock is equipped with the SECOMA Site Manager 1139, enabling remote support, live performance analysis, and seamless integration into your digital factory environment.

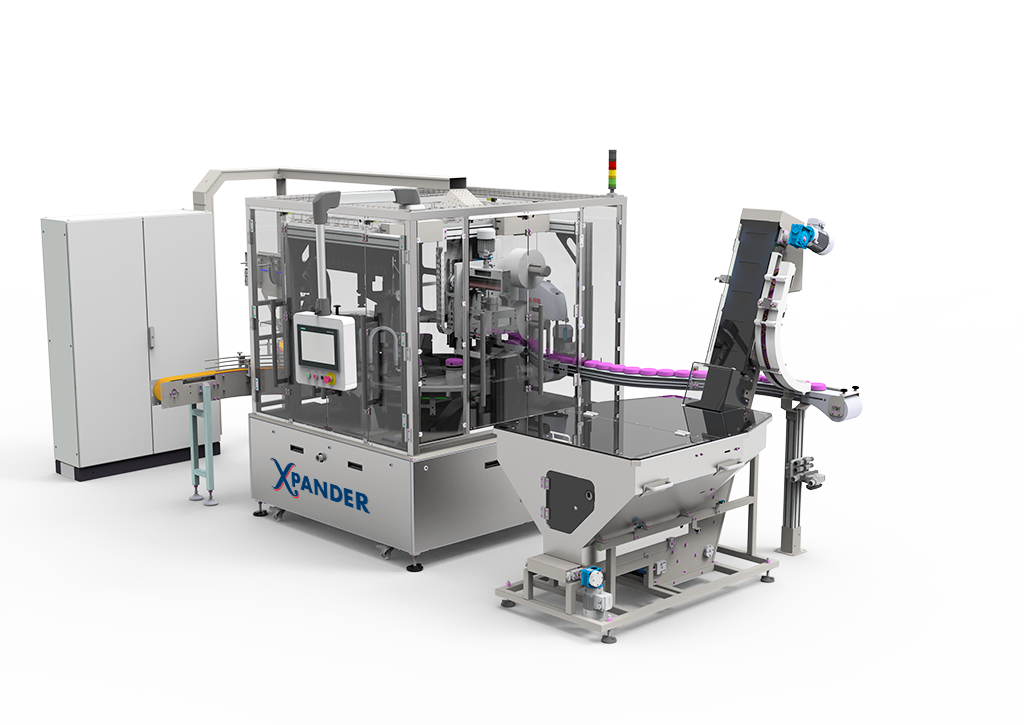

Technical Highlights

- Servo-driven vertical index motion

- ±0.5% dosing accuracy

- 5 conveyors feeding in/out of the monoblock

- Constructed from 316/304 stainless steel (pharma sanitary grade)

- Optional torque control station for screw-on and snap-on caps

Supporting the Wipes Industry

The wipes market is evolving fast, requiring machines that are compact, future-ready, and robust. The Xpander Monoblock Canister Wipes Machine was reimagined to meet these demands through design improvements driven by feedback from the field.

Learn more about Shemesh Automation’s wet wipes packaging technologies at

Shemesh Automation Nonwovens

or visit www.sawetwipes.com.

Industry resources:

INDA – Association of the Nonwoven Fabrics Industry |

Nonwovens Industry Magazine