Gallery

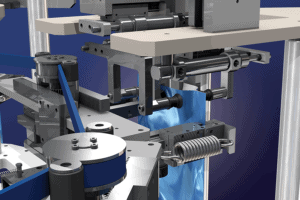

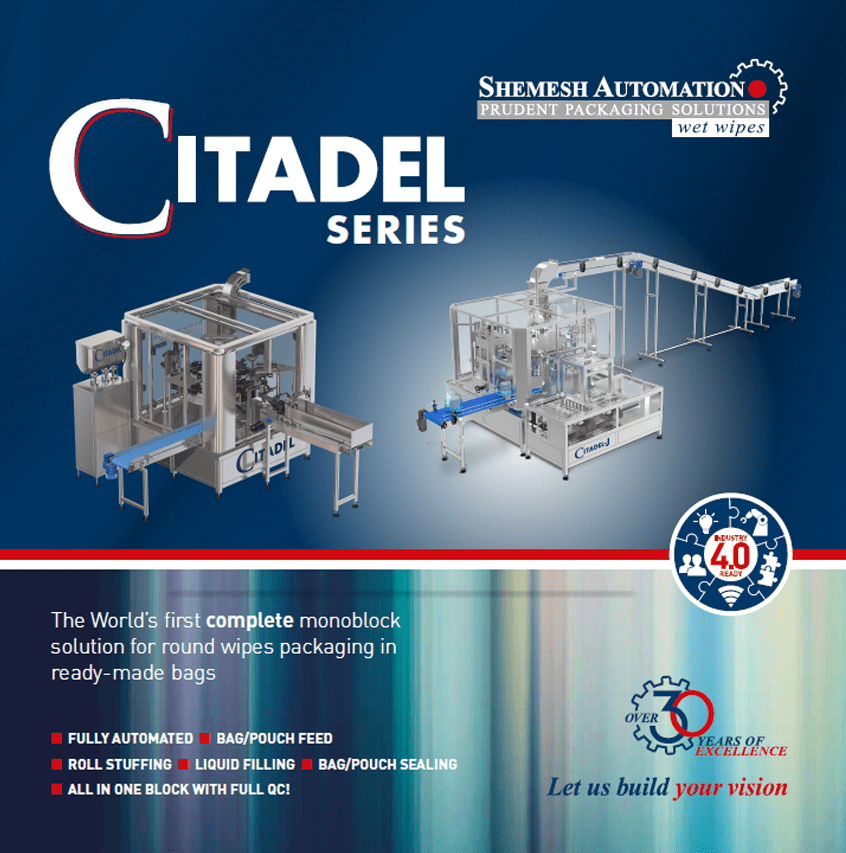

The World’s First Complete Packaging Automation Monoblock Machine For Round Wipes In Flexible Packs

PACKAGING AUTOMATION – BAG/POUCH FEED, ROLL STUFFING, LIQUID FILLING, BAG/POUCH SEALING – ALL IN ONE BLOCK WITH FULL QC!

Built on decades of industry experience supporting the wipes manufacturing sector with our in-line, high throughput downstream packaging portfolio, Shemesh Automation is once again first to market with an all-in-one system designed specifically to serve the round wipes in flexible packaging market.

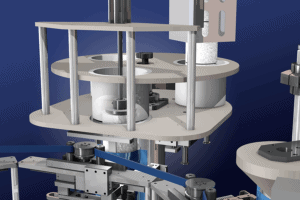

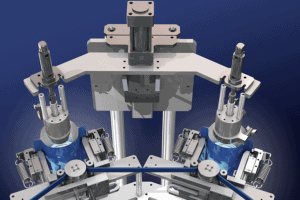

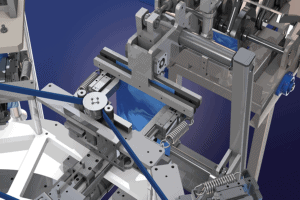

The Citadel Packaging Automation harnesses all the knowledge and innovations that were key to our globally successful Xpander monoblock for wipes in canisters and other nonwovens packaging technologies such as the SAS120 stuffer. The tried and tested all-in-one monoblock design of the Citadel encompasses all aspects of round wipes downstream packaging from bags/pouches feeding, roll stuffing, liquid filling, bag sealing with full built-in QC!

The Citadel has a throughput of up to 30ppm (refill size)/ 8-12ppm (jumbo size) and is the only machine of its kind available on the market today — far exceeding the sophistication of existing market solutions.

Through a process of continual evolution and constant dialogue with our customers the all-new Citadel offers significant productivity enhancements, benefiting manufacturers and boosting efficiency.

Requiring just one person for operation, the Citadel affords flexible and efficient operation and offers exceptional ROI while reducing waste, cutting production times and maintaining high levels of product quality.

In addition, with a monoblock footprint of only 1.8m x 1.8m, the Citadel is capable of operating in very small spaces.

For more information on our full range of Wet Wipes packaging machinery, including solutions for both rigid and flexible packaging, visit our dedicate site, www.sawetwipes.com

Benefits

- Throughput of up to 30ppm (refill size), 8-12 (jumbo size)

- Direct and easy integration to the rewinding unit

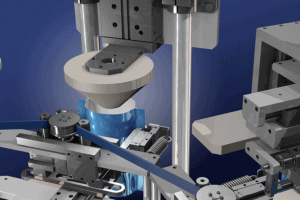

- Closed bags opening feature

- All welded to pharma sanitary standards using 316/304 stainless steel

- Designed for operational flexibility and ultra low, tools free sub 40 minutes format parts changeover downtime

- INDUSTRY 4.0 READY: SECOMA SiteManager 1139 modem, integrated into the machines’ HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback.

- Advanced QC including multiple check-weighers significantly increasing efficiency

- Enhanced, height-adjustable anti-overflow, proprietary designed filler nozzles. Portioning tolerance of 0.5% of filling volume – reducing waste

- Bag inflation: bags are inflated with the exact amount of air needed to facilitate speedy opening and rolls stuffing

- Two-stage filling, minimising foaming and spillover whilst achieving a higher throughput

- A newly developed design for wipes bag loading Easy-to-access ‘smart’ controls with multiple HMI’s around the Citadel for simple operation

- Adjustable rewinder-to-Citadel throughput technology

- Air evacuation