Gallery

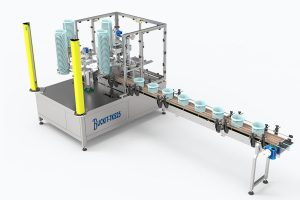

Automatic Buckets Denester – High-Efficiency Bucket Denesting Machine

The Shemesh automatic buckets denester delivers continuous, high-performance bucket handling for industrial lines. It uses a servo-driven vertical stack carousel that holds up to four bucket stacks. As a result, your production line receives a consistent and uninterrupted feed.

Operators load buckets vertically into the rotating magazines of the denester. Meanwhile, the carousel allows reloading on-the-fly, so production never stops. The system then separates each bucket and places it upright on the conveyor. Therefore, downstream processes such as filling, sealing, or labeling run smoothly.

What Is an Automatic Buckets Denester Used For?

In many industries, buckets serve as essential packaging containers. A bucket denester machine automates the task of separating and placing buckets onto the line. Consequently, manufacturers avoid manual destacking, which often slows production and increases labor costs.

The automatic denester improves productivity by cutting downtime and removing repetitive manual work. Moreover, it ensures a stable and continuous supply of buckets to the next stage. This benefit makes the system especially valuable for co-packers and manufacturers handling multiple bucket formats at scale.

Get a Quote Call us: +44 754 620 6583

Industries Served

- Food & Beverage – sauces, condiments, powders, gummies

- Chemicals – adhesives, paints, detergents

- Cosmetics – gels, scrubs, bulk creams

- Nonwovens – wipes in buckets

- Co-packers – for flexible, multi-format bucket lines – Contact us

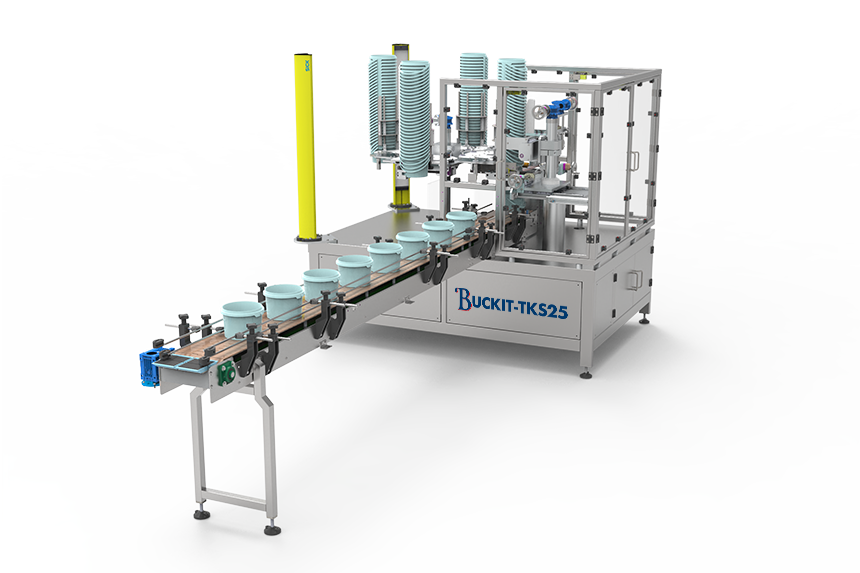

Technical Highlights

- Continuous operation – Reload buckets without stopping the line

- Fast changeovers – Switch bucket types instantly via Siemens or Allen-Bradley PLC & HMI

- Reduces the need for format parts

- Minimizes downtime and manual handling

- Built in stainless steel SST304 – durable and hygienic

- User-friendly HMI control system

- Throughput: Up to 25 buckets per minute

- Capacity: Holds 100–120 buckets across 4 magazines

Follow us on LinkedIn

for more updates on bottling, capping, labeling, and packaging innovations.