Gallery

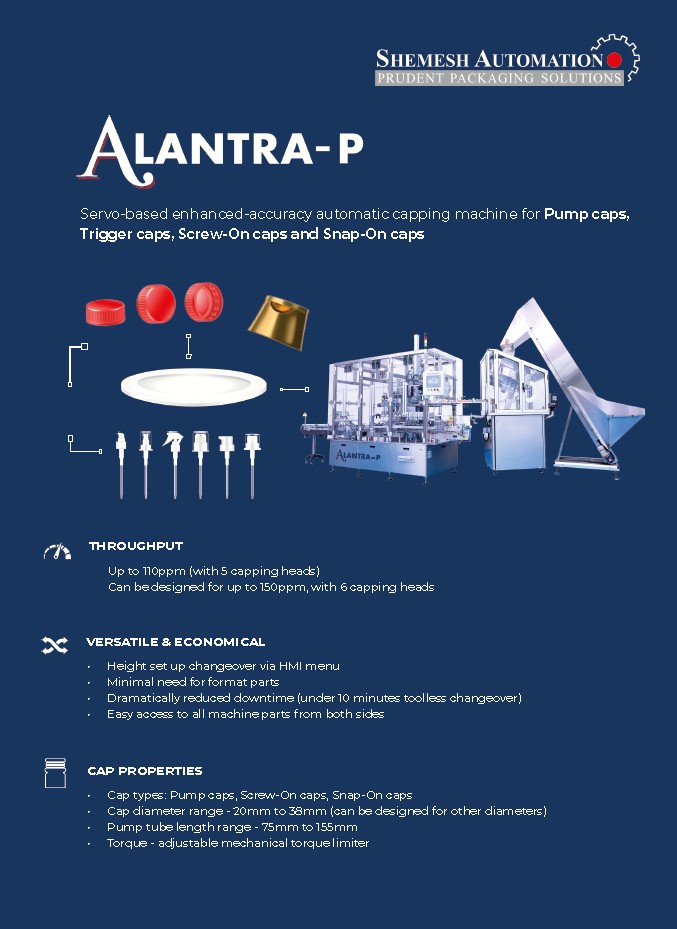

ALANTRA P Automatic Capping Machine: Pump, Trigger, Screw-On & Snap-On Caps

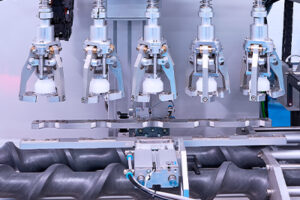

Introducing the ALANTRA P Automatic Capping Machine, a high-speed, high-performance, and exceptionally versatile linear servo-based automatic capping machine, designed for industries requiring precision, speed, fast changeover, low downtime, reliability, and consistency across their packaging processes.

Whether you’re handling screw-on, spray pump, snap-on, or trigger caps, this machine offers the ultimate solution for cosmetics, pharmaceuticals, chemicals, and food & beverage applications. Its servo-driven design ensures exacting torque control, creating a secure, leak-free seal every time.

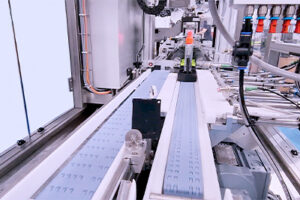

The ALANTRA P is fully integrated with a cap sorting and orientation system for seamless handling of various cap types, ensuring caps are correctly positioned before tightening.

Cap up to 150 ppm with the “six up,” 6-head configuration, ideal for high-demand production environments requiring consistent, high-speed output. Lower throughput versions as low as 40 ppm are also available.

The ALANTRA P’s servo system ensures precise container positioning and torque across the machine.

This model can also come with a built-in dosing system, creating a filler-capper monobloc with technology options like net weight, gear pumps, flow mass, or pistons.

Tailored for Precision Packaging Across Multiple Sectors

The ALANTRA P is built to meet the unique demands of modern packaging lines across diverse industries, designed to work with or without pucks and handle containers from 50ml to 2L.

Cosmetics Applications

The cosmetics industry demands precision and reliability to protect product integrity. The ALANTRA P Automatic Capping Machine is suitable for:

- Serums and Lotions: Leak-free sealing for screw-on and snap-on caps to maintain product efficacy.

- Perfumes and Mists: Handles spray pumps with precise torque control, protecting sensitive products.

- Creams and Gels: Simplifies capping for viscous products with superior snap-on and trigger cap options.

Pharmaceutical Applications

In the pharmaceutical industry, seal integrity is critical to product safety and efficacy:

- Vials Liquid Medications: Provides secure sealing with screw-on or snap-on caps to prevent contamination.

- Nutraceuticals: Suitable for syrups, lotions, and supplements, with precision to prevent leaks.

- Topical Ointments: Trigger caps enable easy dispensing, ensuring effective application without leakage.

Applications for Chemicals

For chemical products, safety and precision are essential. The ALANTRA P is ideal for:

- Household Cleaners: Ensures correct capping for bleach, disinfectants, and trigger spray cleaners to prevent spills.

- Industrial Chemicals: Delivers a secure seal for lubricants, solvents, and detergents, reducing leakage risks.

- Automotive Fluids: Provides exact torque control for motor oil, coolants, and windshield fluids for reliable sealing.

Food and Beverage Applications

Maintaining product freshness and preventing leakage is essential in the food and beverage industry:

- Sauces and Condiments: Ideal for viscous products like sauces, dressings, and syrups with secure snap-on or screw-on caps.

- Beverages: Ensures tight capping for juices, energy drinks, and spirits, preserving product quality and shelf life.

- Honey and Syrups: Capable of handling trigger caps and pump caps for viscous liquids like honey, preventing waste or leaks.

Benefits

- High Throughput: Cap up to 150 ppm with the “Six up” 6-head configuration, ideal for high-demand production environments.

- Servo-Driven Precision: Ultra-accurate torque settings for consistent capping force, preventing leaks and reducing waste.

- Versatile Cap Customization: Supports a range of cap diameters, adaptable for custom sizes upon request.

- Automated Cap Feeding: Fully automated feeding and placement of caps, enhancing efficiency by minimizing manual handling.

- Quick Changeover: Allows fast switching between cap types, reducing downtime and boosting productivity.

- Industry 4.0 Compatibility: Equipped with SECOMA Site Manager 1139 for live monitoring, remote diagnostics, and performance feedback.

- Precise Torque Control: Adjustable torque for accurate cap application, essential for fragile products.

- Built-In Quality Control: QC and reject conveyor detect and remove defective containers from the line.

For more information on our automated packaging machinery, contact us today to discuss how we can meet your unique packaging requirements.

Follow us on LinkedIn for updates on our latest news and innovations in filling, capping, and sealing solutions.