Gallery

ALANTRA Automatic Air Pump & Trigger Nozzle Capper

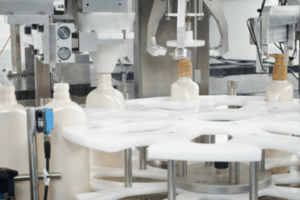

Cap-off your in-line system with the ultra-accurate ALANTRA Automatic Air Pump and Trigger Nozzle Capper Machine!

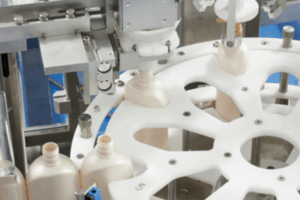

From cleaning products with trigger nozzles to cosmetics products with air pumps, Shemesh Automation’s ALANTRA is designed to provide accurate, efficient torque-measured capping for a wide variety of industries.

Specifically designed to provide super-accurate leak-free capping, the ALANTRA is available in both semi-automatic and fully automatic versions for maximum efficiency and versatility. ALANTRA is applicable to containers common to the chemical & cosmetics, pharmaceuticals & food and beverage industries.

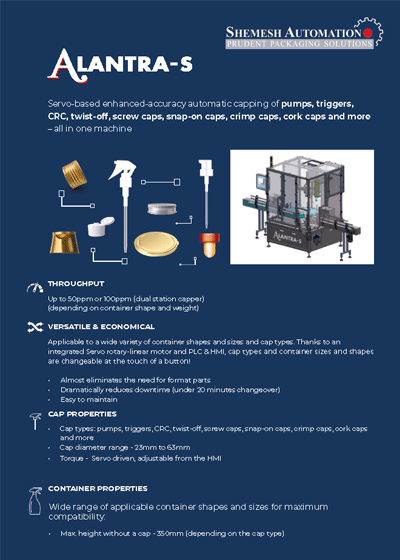

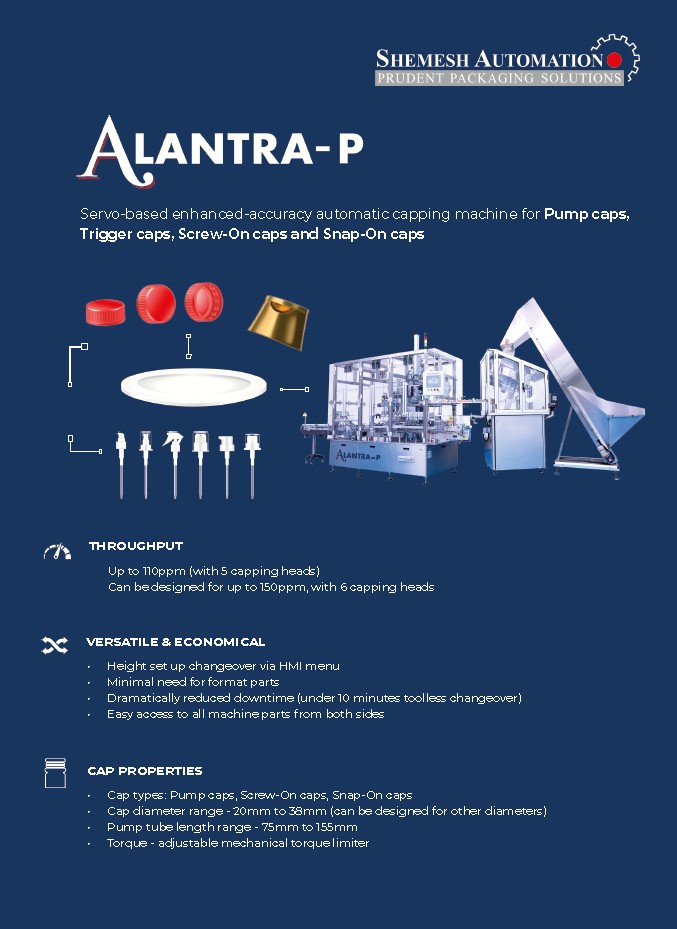

The ALANTRA Automatic Air Pump and Trigger Nozzle Capping Machine has optional built-in capping quality control and its defects rejection system guarantees a less than 1% defect rate – reducing waste and downtime. ALANTRA’s tool-free design offers a sub 20-minute changeover and reduced downtime, further enhancing the productivity of your line regardless of how many different product types run through it.

Like all machines in the Shemesh range, the ALANTRA is INDUSTRY 4.0 READY. It includes as standard a SECOMA SiteManager 1139 modem, integrated into the machine HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback.

Automatic Trigger Nozzle Capper Machine Benefits

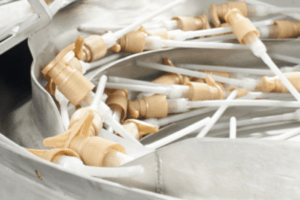

- Trigger and/or spray pump automatic feeding, orientation & capping

- Semi-automatic (accommodates up to 2 operators) or fully-automatic (for hands-free operation) models available

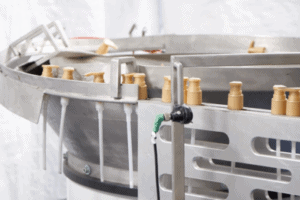

- Throughput: 60 containers/min or up to 120 containers/min (double station)

Sanitary design - Handles wide variety of containers, bottles and shapes (eg plastic, glass, round, square, cylindrical, conical, etc)

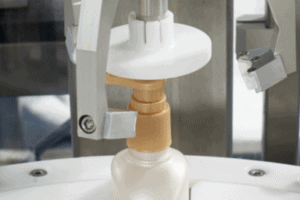

- Pick & Place method for accurate capping

- Digital, servo-driven adjustable torque for flexibility and precision

- Universal proprietary gripper fits both spray and trigger caps. No tools, no downtime required

- Optimised footprint

- Built-in capping quality control to examine defects (if there is no cap or if the cap is not closed properly) and defects rejection system

- Accurate – under 1% defect rate guaranteed – delivers saving through reduced waste and downtime

- Tool-free design offers sub 10-minute changeover (!) and reduced downtime

- Monoblock style version or linear line version available for hands-free operation and footprint reduction

Contact us for more information on our range of Capping Machinery or for a full quotation – let us build your vision!