Accumulation Table

Accumulation Tables

What is an Accumulation Table?

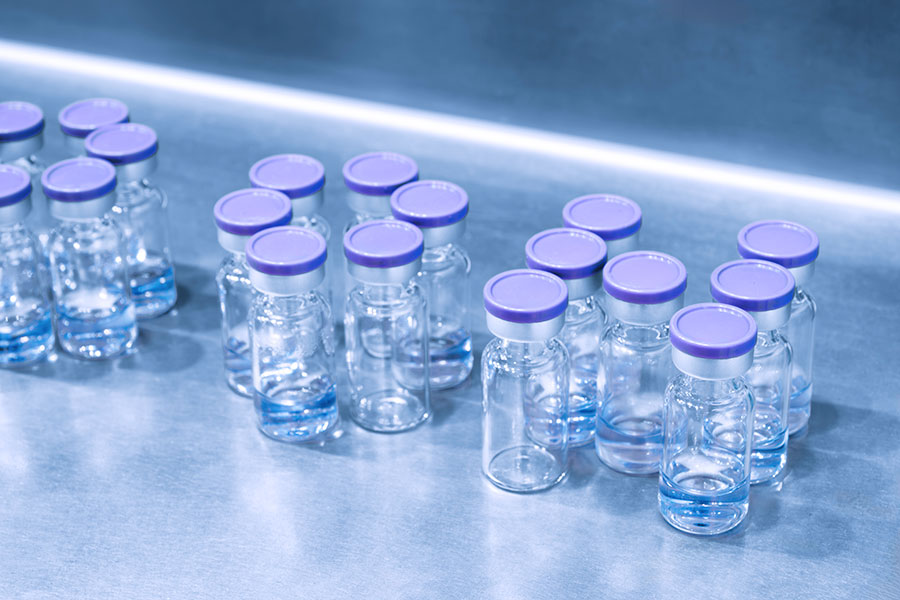

An accumulation table is a key end-of-line component in automated packaging systems, designed to temporarily hold and buffer containers such as bottles, jars, or tubs. Commonly used in the food & beverage, cosmetics, chemicals, and nonwovens sectors, an accumulation table helps balance the flow between upstream and downstream machines, preventing bottlenecks and maintaining a smooth production rhythm.

How Does an Accumulation Table Work?

Positioned between two machines in a production line-such as between a filler and a labeler or a capper and a case packer-the accumulation table receives filled or capped products, storing them momentarily before releasing them to the next stage. This buffering function compensates for speed differences between machines, short stops, or temporary slowdowns, ensuring that production keeps moving even if one machine pauses.

Accumulation tables are typically circular (rotary) or straight-line conveyors with controlled feeds and exit zones, and may include sensors or guides to regulate flow and avoid product overlap or jams.

What Are the Benefits of an Accumulation Table?

- Smooth production flow by minimizing downstream disruptions

- Increased throughput and uptime across the line

- Reduced product damage thanks to gentle buffering

- Space efficiency with compact footprints available

- Boosted overall equipment effectiveness (OEE)

Our accumulation tables integrate seamlessly with automatic case packing machines, Shemesh capping machines, and SealPro conduction sealing machines.

What Are the Different Types of Accumulation Table?

- Rotary Accumulation Tables – Circular tables ideal for round containers and medium-speed lines

- Inline Accumulation Conveyors – Straight-line buffers for high-speed or irregular-shaped containers

- Mass Accumulation Systems – Large-scale systems for high-volume, continuous flow operations

- Custom Multi-Lane Tables – Used in cosmetics or chemical industries for parallel accumulation

Our Accumulation Table

Shemesh Automation offers robust and reliable accumulation tables as part of our end-of-line packaging solutions. Designed with hygienic stainless steel construction and seamless integration in mind, our accumulation tables ensure continuous flow between Shemesh fillers, cappers, labelers, sealers, and case packers.

- Adjustable height and speed

- Smooth rotary or inline accumulation surfaces

- Gentle product handling with minimal backpressure

- Easy cleaning and maintenance access

- Compact footprint with optional custom configurations

Frequently Asked Questions (FAQs)

Why choose Shemesh Automation for my automation needs?

With over 30 years of expertise and thousands of machines deployed globally, Shemesh Automation delivers premium packaging equipment, built for performance, integration, and long-term support.

What warranties and after-sales support will I receive?

All Shemesh machines come with a 12-month standard warranty (extendable), access to remote and on-site support, spare parts, and global service hubs in the US, UK, France, and Israel.

Can Shemesh customise a machine for my factory’s specific needs?

Yes. Our team can tailor any machine, including accumulation tables, to match your specific product, line layout, and speed requirements, ensuring optimal performance in your facility.

Get in Touch

For more information on the Accumulation Conveyor & Accumulation Table Conveyor, and to discuss how we can meet your unique packaging requirements.

Follow us on LinkedIn for updates on our latest innovations.