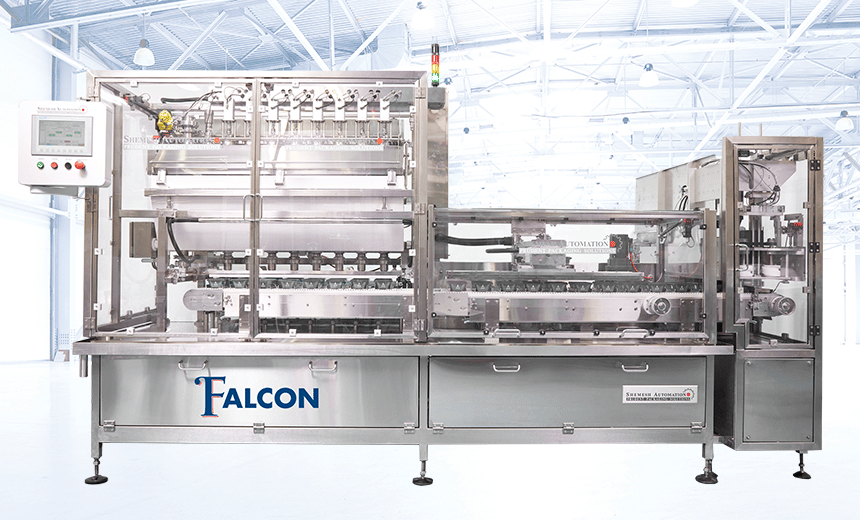

Shemesh’s FALCON Net Weight Liquid Filling Machine was the subject of an article in the November/December edition of Machinery Update. You can read the full piece on pg18 here.

Filling Machine Delivers for the Chemical Industry

Shemesh has launched a net weight liquid filling machine for thin liquids featuring hot fill of viscous and abrasive materials.

Called the FALCON, the machine incorporates the Shemesh DEENEX Denester as well as a special parallel servo-driven indexing conveyor for maximizing throughput potential. It has been developed primarily to target the chemical sector. However, the creative design also makes it suitable for filling food, such as tubs of tahini and hummus.

The machine design combines a clever sequence of technologies that can load, sort, fill and package a variety of cleaning agents, creams and pastes. Using gravity or other positive displacement methods of filling ensures almost pin-point net weight accuracy, says the company.

There are many materials that are sensitive to specific gravity changes due to temperature and this new filling equipment will accurately control the net weight to help manufacturers comply with legislation.

Shemesh’s VP Global Sales & Business Development, Yonatan Levy, says the Falcon is built for long-term durability, avoiding the common problem of degradation of machine parts by harsh materials. « What sets it apart from its competitors is its parallel infeed system, which is used to maximise the throughput from the denester. » He says.

« The tank and nozzles design guarantees that the liquid path is free from any kind of mechanical parts such as pistons and seals which can suffer from wear and tear because of the abrasiveness of certain materials.”

The PLC and HMI controls both the filler and the denester which essentially creates a single combined unit.

The Falcon is also easily and rapidly adjustable. All parts are tool-less for quicker changeover times, which are less than 15 minutes – a benefit for more niche producers switching between product lines more frequently.

You can read the original article, which was published on pg 18 of the November/December 2022 edition here